Feed manipulator of spring bars former

A molding machine and manipulator technology, which is applied in the field of manipulators, can solve the problems that technical workers cannot maintain, robot application restrictions, poor working environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below according to the drawings and embodiments.

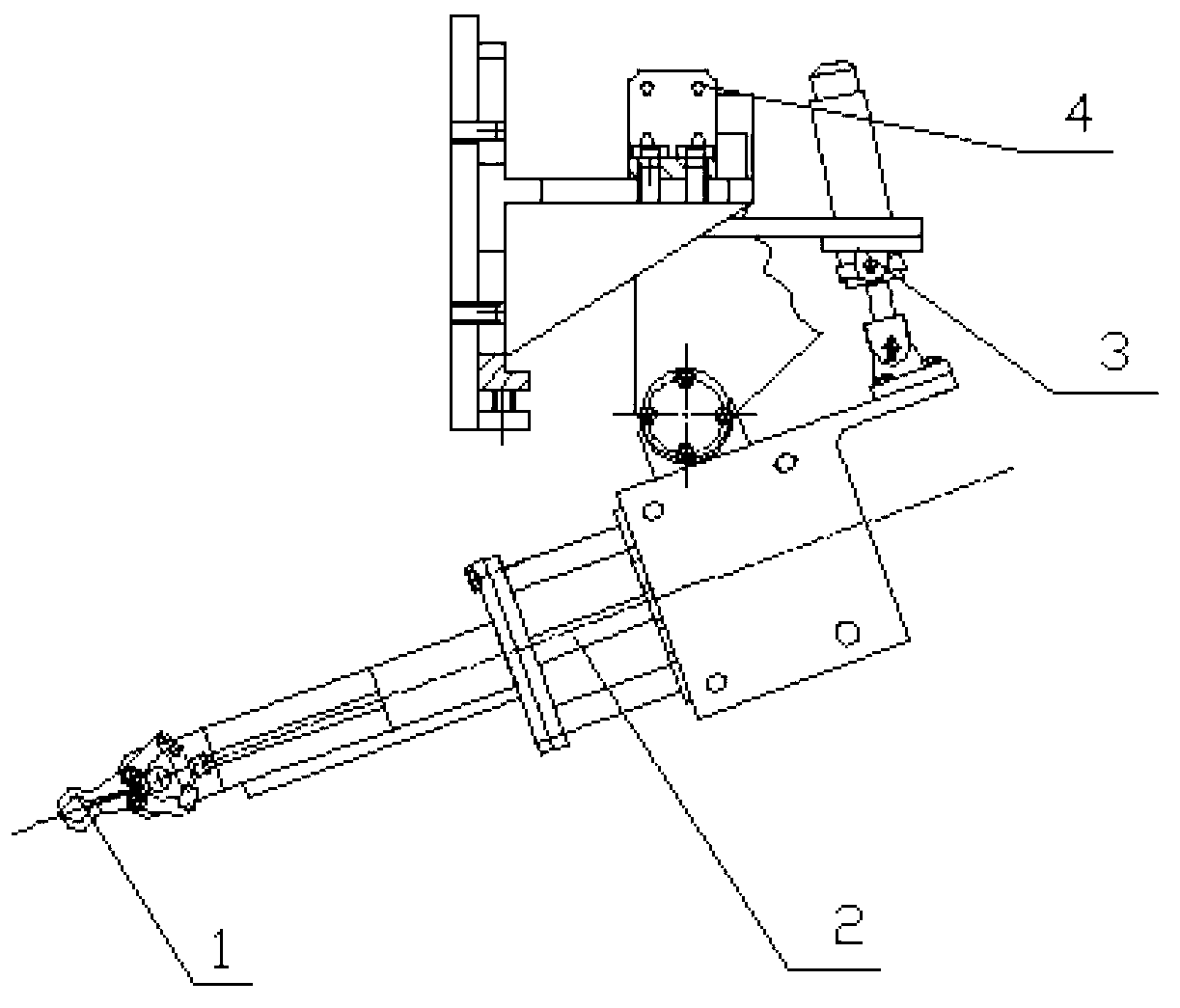

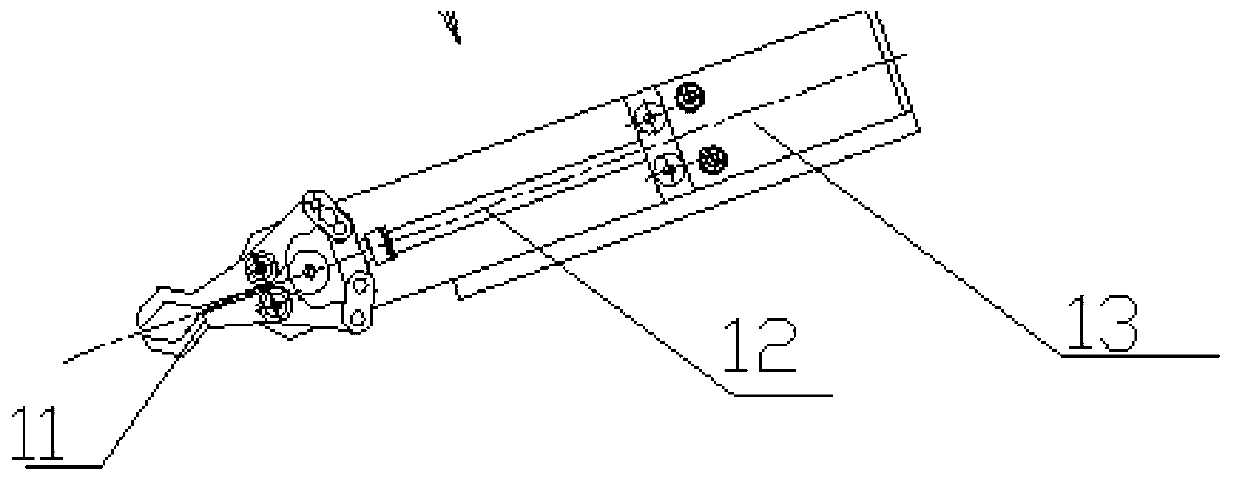

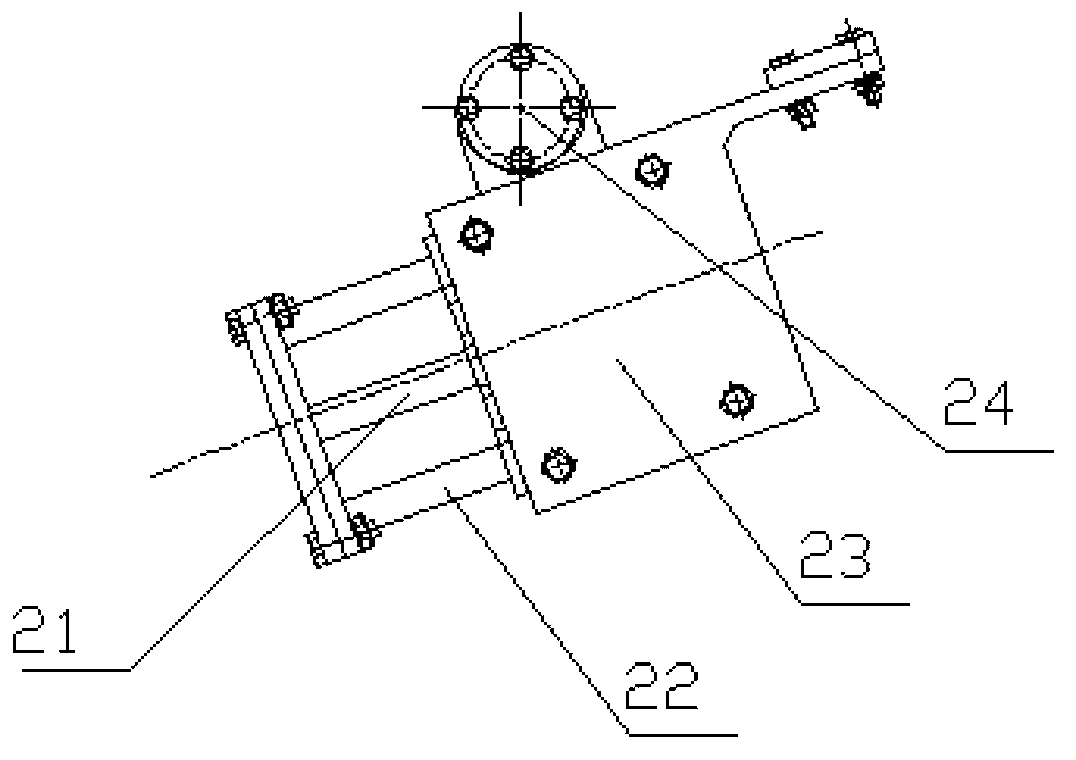

[0020] figure 1 For the structural diagram of the feeding manipulator of the elastic strip forming machine in this implementation case, refer to figure 1 , the feeding manipulator of the elastic strip forming machine, including a grabbing mechanism 1, a telescopic mechanism 2, a rotating mechanism 3, and a lateral movement mechanism 4. Wherein, the side of the above-mentioned telescopic mechanism 2 is connected with the above-mentioned grasping mechanism 1, and the telescopic mechanism 2 can expand and contract along the direction of the above-mentioned grasping mechanism 1. Make the above-mentioned telescopic mechanism 2 and the above-mentioned grasping mechanism 1 swing on the vertical plane where the connection of the above-mentioned telescopic mechanism 2 and the above-mentioned rotating mechanism 3 is the center point, the above-mentioned rotating mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com