Supporting device for assembling chassis

A technology for supporting equipment and chassis, which is applied in transportation and packaging, workpiece clamping devices, motor vehicles, etc., and can solve problems such as complex layout, squatting or even lying on the ground, and small working space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

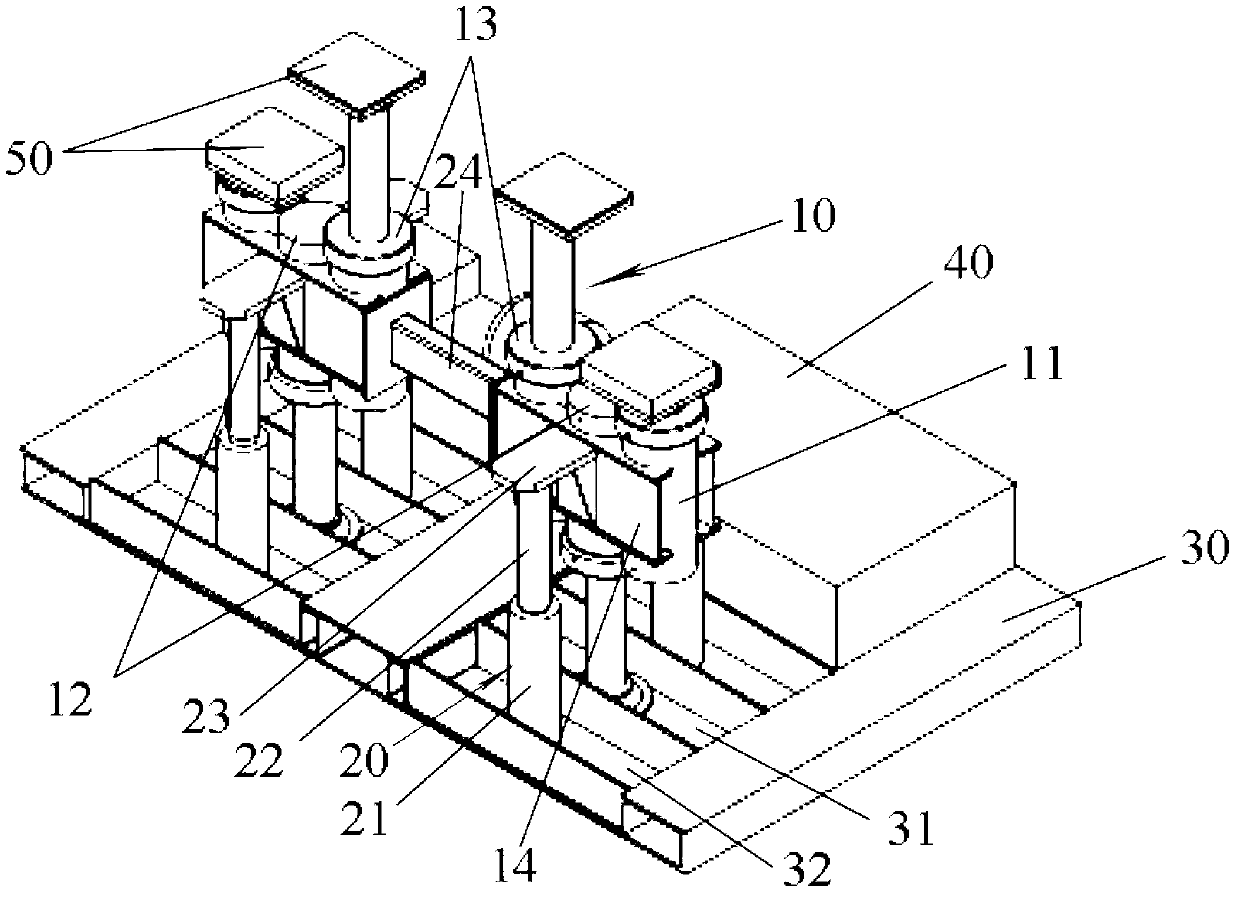

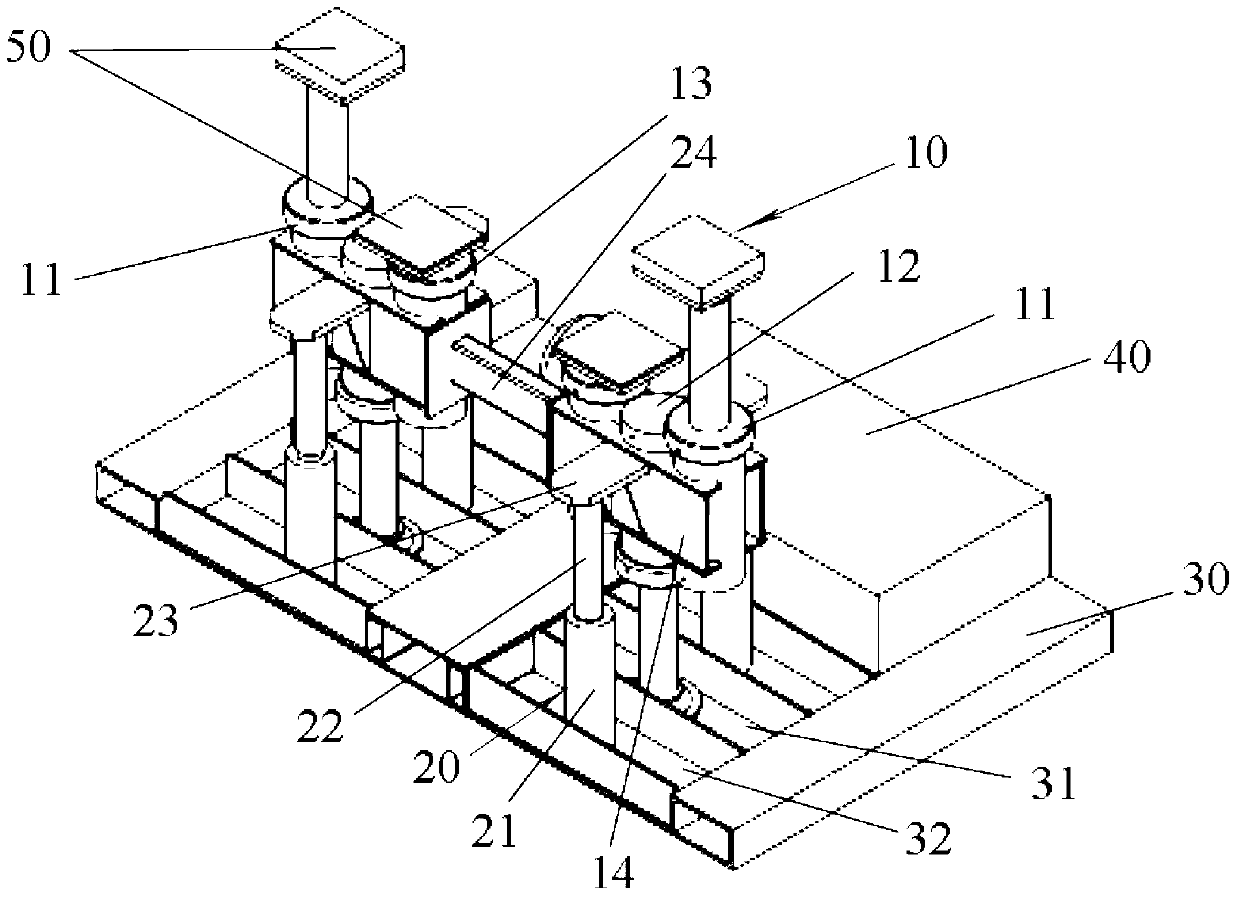

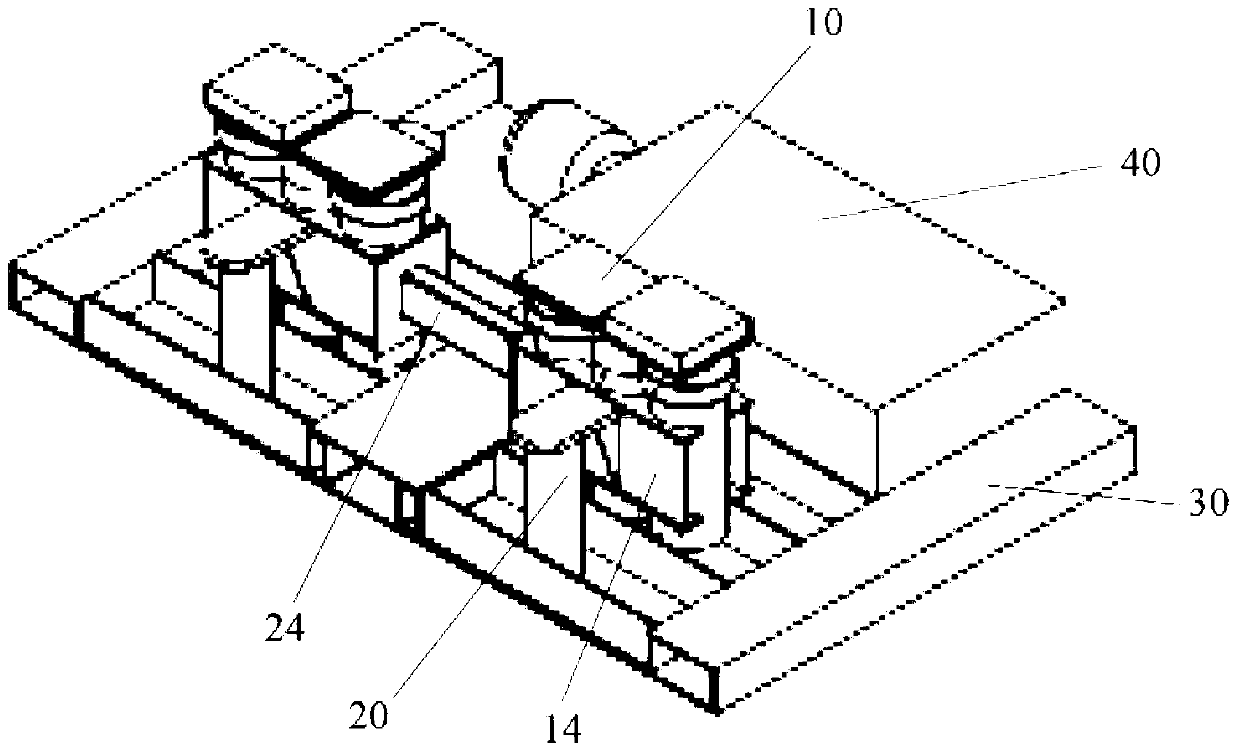

[0038] More preferably, the two lifting devices 10 are arranged in such a manner that the distance between the two lifting devices 10 is adjustable, so that the supporting position can be adjusted correspondingly according to the different models and sizes of the chassis of the supported cranes. Wherein, the two lifting devices 10 can be arranged in various appropriate ways, as long as the distance can be adjusted. Although a specific embodiment will be described in detail below, the present invention is not limited thereto.

[0039] In a preferred embodiment of the present invention, each lifting device 10 may include a first oil cylinder 11 and a second oil cylinder 12, the cylinder body of the first oil cylinder 11 is fixedly connected to the cylinder body of the second oil cylinder 12, The piston rod of the first oil cylinder 11 and the piston rod of the second oil cylinder 12 protrude in opposite directions.

[0040] More preferably, as Figure 1 to Figure 3 As shown, e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com