A method for quick replacement of hoisting motor pulley blocks and wire ropes

A technology of moving pulley block and wire rope, applied in the direction of spring mechanism, hoisting device, etc., can solve the problems of low degree of automation, long time consumption, large labor workload, etc., and achieves the improvement of safety, time saving and cost saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The specific implementation manner of the invention will be described below in conjunction with the accompanying drawings.

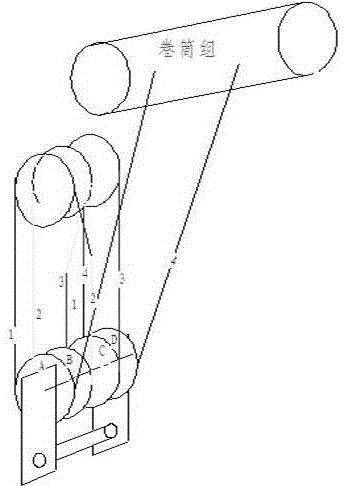

[0010] as attached figure 1 As shown, first drop the old moving pulley block to be replaced to a suitable position, and at the same time operate the hoisting system to make the wire rope continue to fall until the last two turns of the wire rope wound on the drum remain. figure 1 Among them, 1, 2, 3, and 4 are steel wire ropes wound in different moving pulleys respectively. A, B, C, and D represent movable pulleys. The steel wire rope 1 enters the movable pulley A from the drum, and then winds up into the fixed pulley, and then winds down and enters the movable pulley B, while the movable pulley C is the reversing movable pulley. The left side winds down and enters the movable pulley D, and the right side of the driven pulley D enters the pressure plate on the other side of the drum upwards. This is the way the entire wire rope is wound on this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com