Amphiprotic leather tanning agent and preparation method thereof

A technology for retanning agent and leather, applied in the field of amphoteric leather retanning agent and its preparation, can solve the problems of leather retanning, insufficient dyeing performance, etc., and can improve the glass transition temperature is too high, the amount of dyes is reduced, and the degree of branching is improved. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

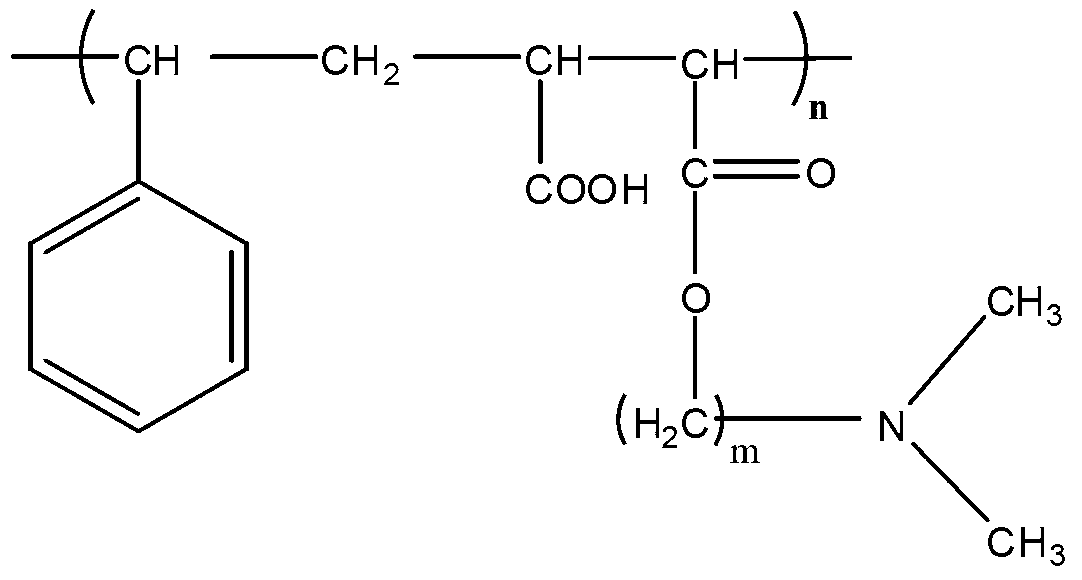

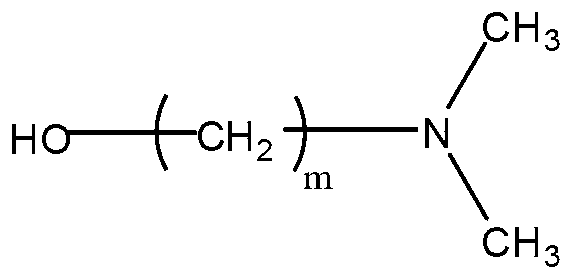

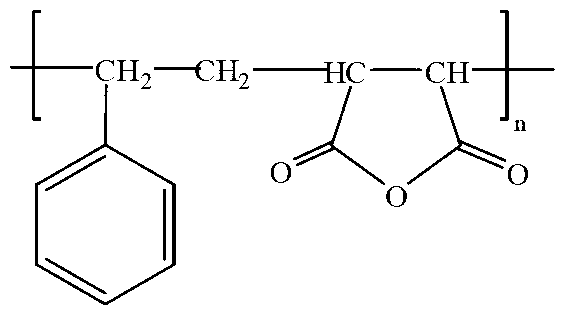

[0036] A preparation method of an amphoteric leather retanning agent, comprising the following steps:

[0037] In terms of parts by mass, add 202 parts of SMA copolymer, 75 parts of N,N-dimethylmethanolamine and 1.385 parts of p-toluenesulfonic acid to the reactor equipped with a condensing device, and add solvent twice the total amount of reactants 554 parts of dioxane, react at 85°C for 3 hours, measure the hydroxyl value in the reaction system, calculated as solids, when the hydroxyl value is less than or equal to 10 (mgKOH / g), add 126 parts of dimethyl sulfate, at 85°C Reaction at low temperature for 3.5h, then vacuum distillation at 0.08Mpa and 80°C for 1h to remove dioxane, finally adjust the pH to 7.0 with 10% NaOH aqueous solution, and adjust the moisture content so that the active ingredient of the product is 30% That's it.

[0038] The physical properties of the amphoteric leather retanning agent prepared in this example: Appearance, colorless or slightly light yell...

Embodiment 2

[0040] A preparation method of an amphoteric leather retanning agent, comprising the following steps:

[0041] In terms of parts by mass, add 202 parts of SMA copolymer, 89 parts of N,N-dimethylethanolamine and 1.455 parts of p-toluenesulfonic acid to the reactor equipped with a condensing device, and add solvent D 582 parts of ketone, react at 90°C for 2.5h, measure the hydroxyl value in the reaction system, calculated as solid, when the hydroxyl value is less than or equal to 10 (mgKOH / g), add 126 parts of dimethyl sulfate, under the condition of 90°C React for 3 hours, then distill under reduced pressure at 0.08Mpa and 80°C for 1 hour to remove butanone, and finally adjust the pH to 6.0 with 20% ammonia solution, and adjust the moisture content so that the active ingredient of the product is 25%.

[0042] The physical properties of the amphoteric leather retanning agent prepared in this example: Appearance, colorless or slightly light yellow transparent liquid; Odor, slight...

Embodiment 3

[0044] A preparation method of an amphoteric leather retanning agent, comprising the following steps:

[0045]In terms of parts by mass, add 202 parts of SMA copolymer, 103 parts of N,N-dimethylisopropanolamine and 1.525 parts of sulfuric acid to the reactor equipped with a condensing device, and add solvent DMSO610 twice the total amount of reactants Parts, react at 90°C for 3 hours, measure the hydroxyl value in the reaction system, in terms of solids, when the hydroxyl value is less than or equal to 10 (mgKOH / g), add 126 parts of dimethyl sulfate, react at 95°C for 4 hours, Then distill under reduced pressure at 0.07Mpa and 80°C for 1 hour to remove DMSO, and finally adjust the pH to 6.5 with 10% KOH aqueous solution, and adjust the moisture content so that the active ingredient of the product is 35%.

[0046] The physical properties of the amphoteric leather retanning agent prepared in this example: Appearance, colorless or slightly light yellow transparent liquid; Odor, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com