Small lifting film coating device

A small-scale device and coating technology, applied in the direction of solid-state chemical plating, metal material coating process, coating, etc., can solve the problems of waste of raw materials and inability to process multiple substrates at the same time, so as to avoid mechanical vibration and structure Simple, Inexpensive Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Example 1: The specific operation process of a small device for pulling and coating

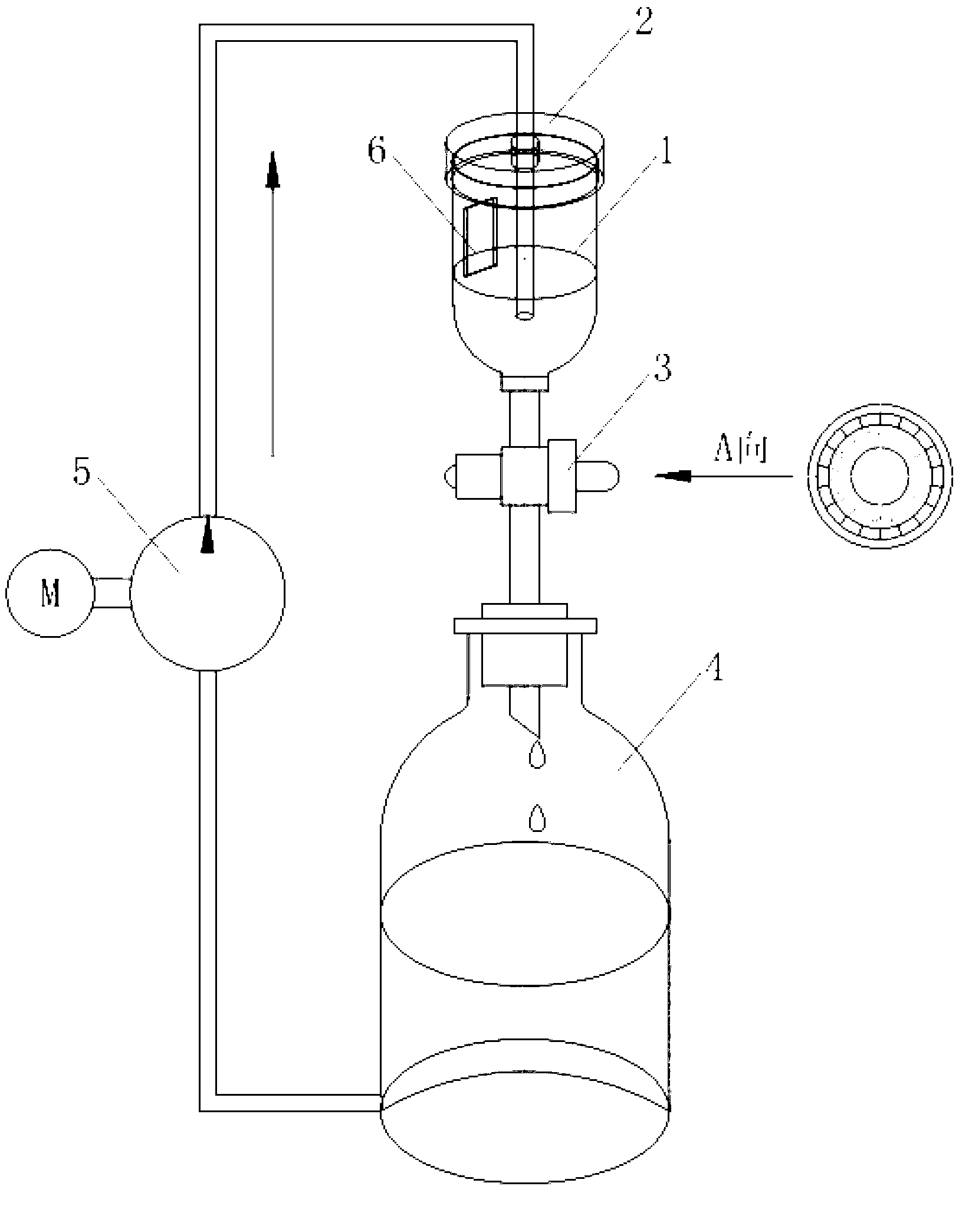

[0016] The first step: if figure 1 As shown, the production device is installed, and the various pipelines between them can be disassembled and can be installed in a sealed manner. Connect the bottom of the liquid storage bottle 4 to one end of the mechanical pump 5 , and the other end of the mechanical pump 5 extends into the coating container 1 through the opening of the coating container cover 2 through the pipeline. The outlet end of the coating container 1 is connected with a liquid storage bottle 4 through a valve 3 . Connect the devices in this order;

[0017] Step 2: Open the coating container cover 2, place the substrate 6 in the coating container 1 and pour the prepared plating solution (the substrate 6 can be fixed with a clip, or a bracket can be fixed in the coating container 1 in advance , to fix the substrate 6 on it, etc.), then cover the coating container cover 2 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com