Monorail tramcar rail using rising and falling parallel turnout

A technology for monorail trams and turnouts, applied to tracks, roads, buildings, etc., which can solve the problems of limited train running intervals, complex turnout structures, and time-consuming moving, and achieve the effects of less oppression, simple construction, and cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

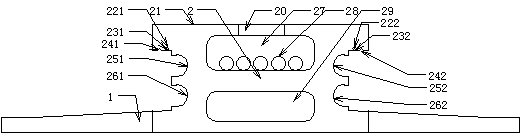

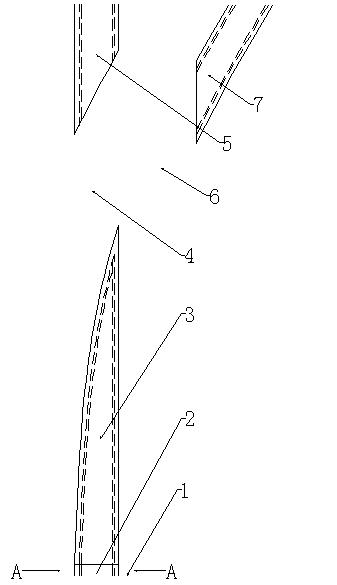

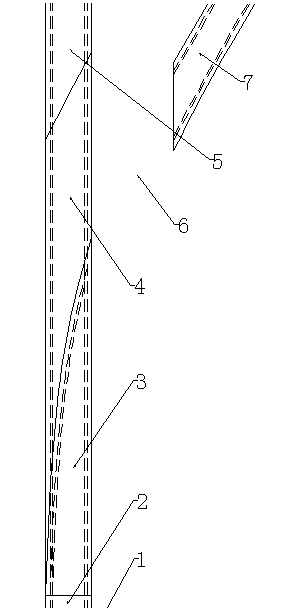

[0010] The invention relates to a monorail tram track, in particular to a monorail tram track adopting a lifting parallel switch. Such as figure 1 - Figure 4 Shown: Including conjoined floor 1 (option), monorail trunk track 2, turnout fixed root 3, turnout straight lifting movable body 4, straight trunk rail fixed joint 5, turnout turning lifting movable body 6, turning trunk rail fixed joint 7 . Among them, the monorail trunk track 2 has a track skeleton 21, a left power line porcelain tank 221, a right power line porcelain tank 222, a left power line 231, a right power line 232, a left water isolation tank 241, a right water isolation tank 242, and upper left horizontal clamping wheels Groove 251, upper right level clip row wheel groove 252, lower left horizontal clip row wheel groove 261, lower right horizontal clip row wheel groove 262, upper material removal hole 27, communication control cable 28, lower material removal hole 29, track patio 20.

[0011]The present in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com