Highway guardrail

A highway guardrail and guardrail technology, which is applied to roads, roads, road safety devices, etc., can solve problems such as collision and troublesome removal of guardrail posts, and achieve the effects of protecting the base post, easy to implement, and convenient to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

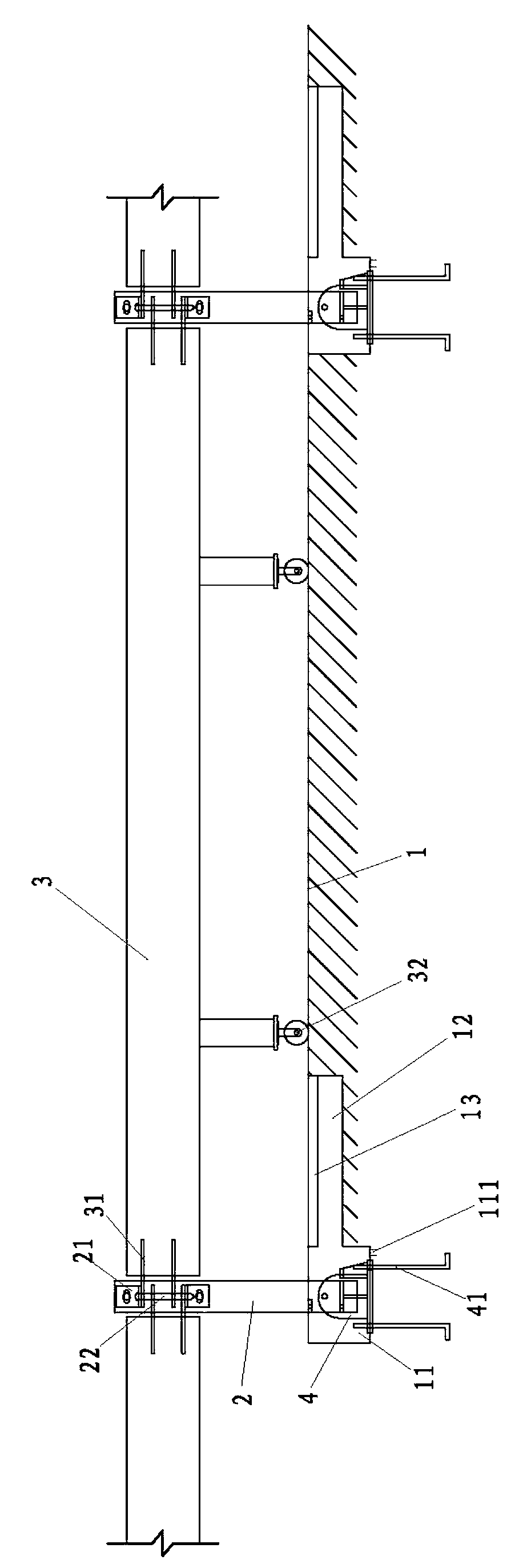

[0017] Example: such as figure 1 Shown, a kind of highway guardrail comprises ground 1, and ground 1 has foundation pit 11, and foundation pit 11 is provided with base 4, and base 4 is provided with the firm rib 41 that goes deep into ground 1 to fix base 4, in There is also a drainage hole 111 on the foundation pit 11; the base column 2 is rotatably connected to the base 4; the ground 1 is provided with a groove 12 that communicates with the foundation pit 11 and can accommodate the foundation column 2; the groove 12 is provided with a groove Cover 13; the inner wall of the groove 12 should be provided with a flange or a step on the inner wall to accommodate the tank cover 13, and the flange or step is not shown in the figure.

[0018] The guardrail body 3 between the adjacent base columns 2; the base column 2 is provided with a positioning piece 21 with a positioning hole; the guardrail body 3 is provided with an insertion piece 31 with a jack; Pin 22 is inserted; for the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com