Rotary tool apron structure capable of being quickly disassembled and assembled of coal plough

A technology of rotary blades and coal plows, applied in the field of coal plows, which can solve the problems of difficult replacement and trimming of plow holders, affecting coal mine production efficiency, long working hours, etc., and achieves compact structure, fast operation, and low operating costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

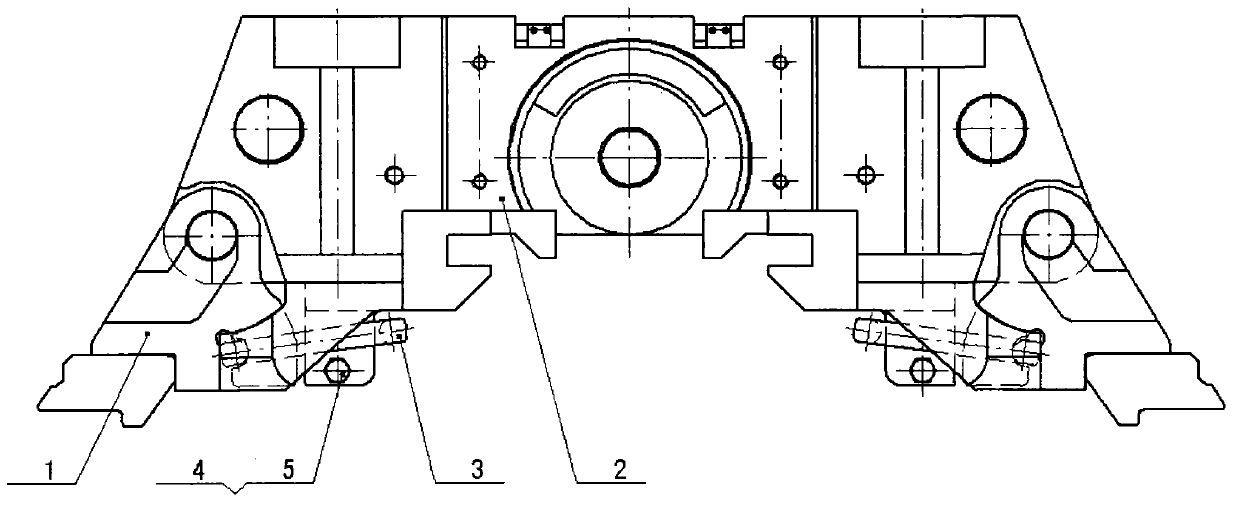

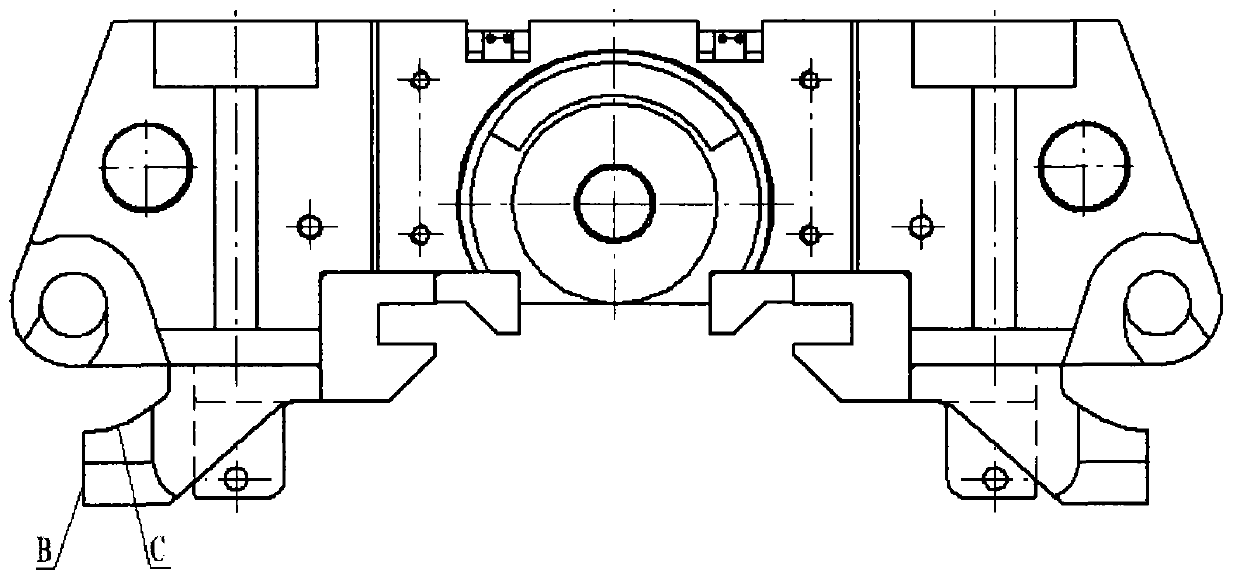

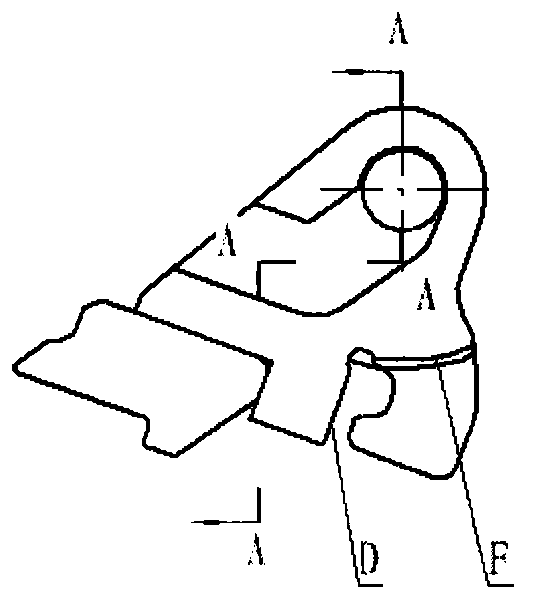

[0016] In the figure: 1. Rotary tool holder; 2. Planer body; 3. Long ring; 4. Bolt; 5. Nut; B. Vertical surface of planer body limit boss; C. Planer body limit boss arc track ; D. The positioning surface of the rotary tool holder; F. The arc surface of the rotary tool holder.

[0017] It can be seen from the figure that the structure of the quick disassembly and assembly rotary knife seat of the coal plow is composed of a rotary knife seat 1, a planer body 2, a long ring 3, a bolt 4 and a nut 5; There are grooves, and cooperate with the circular boss of planer body 2, and pin shafts are respectively welded to the lower ends of the upper boss and the lower boss; the upper plane of the upper boss is provided with guide grooves; the rotary tool holder 1 There is a positioning surface D at the rear of the upper boss and the lower boss, and the positioning surface D is a plane; the upper and lower parts of the right side of the rotary tool holder 1 are the arc surface F of the rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com