Tail-end vibration damper based on rapid energy decay and control method of tail-end vibration damper

A technology of a vibration damping device and a control method, which is applied in the directions of shock absorbers, shock absorbers, springs/shock absorbers, etc., can solve the problems of limited application scope, complicated control schemes, poor low frequency vibration suppression effect, etc. The effect of increasing work efficiency, increasing work speed and range, and reducing control complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

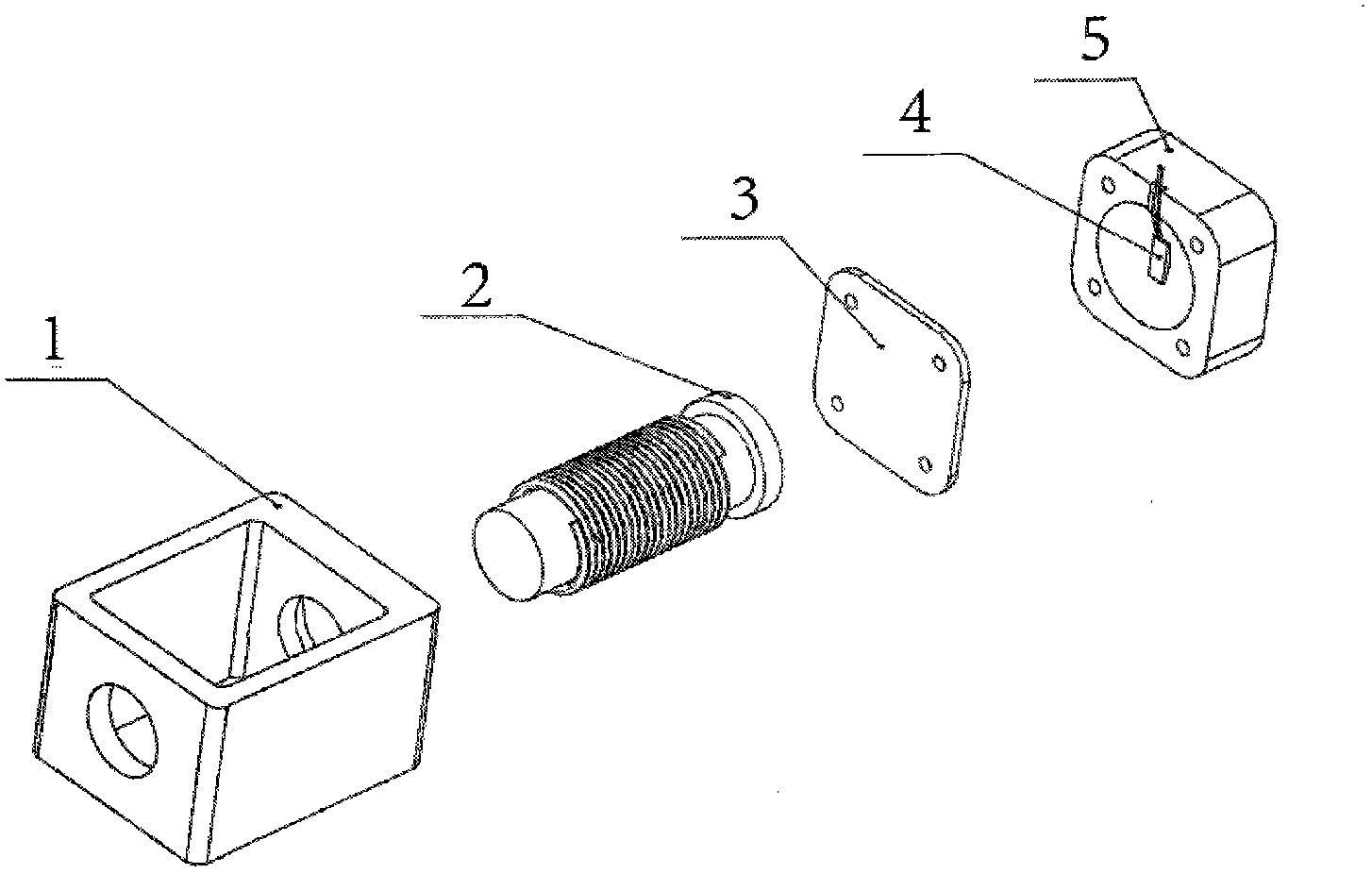

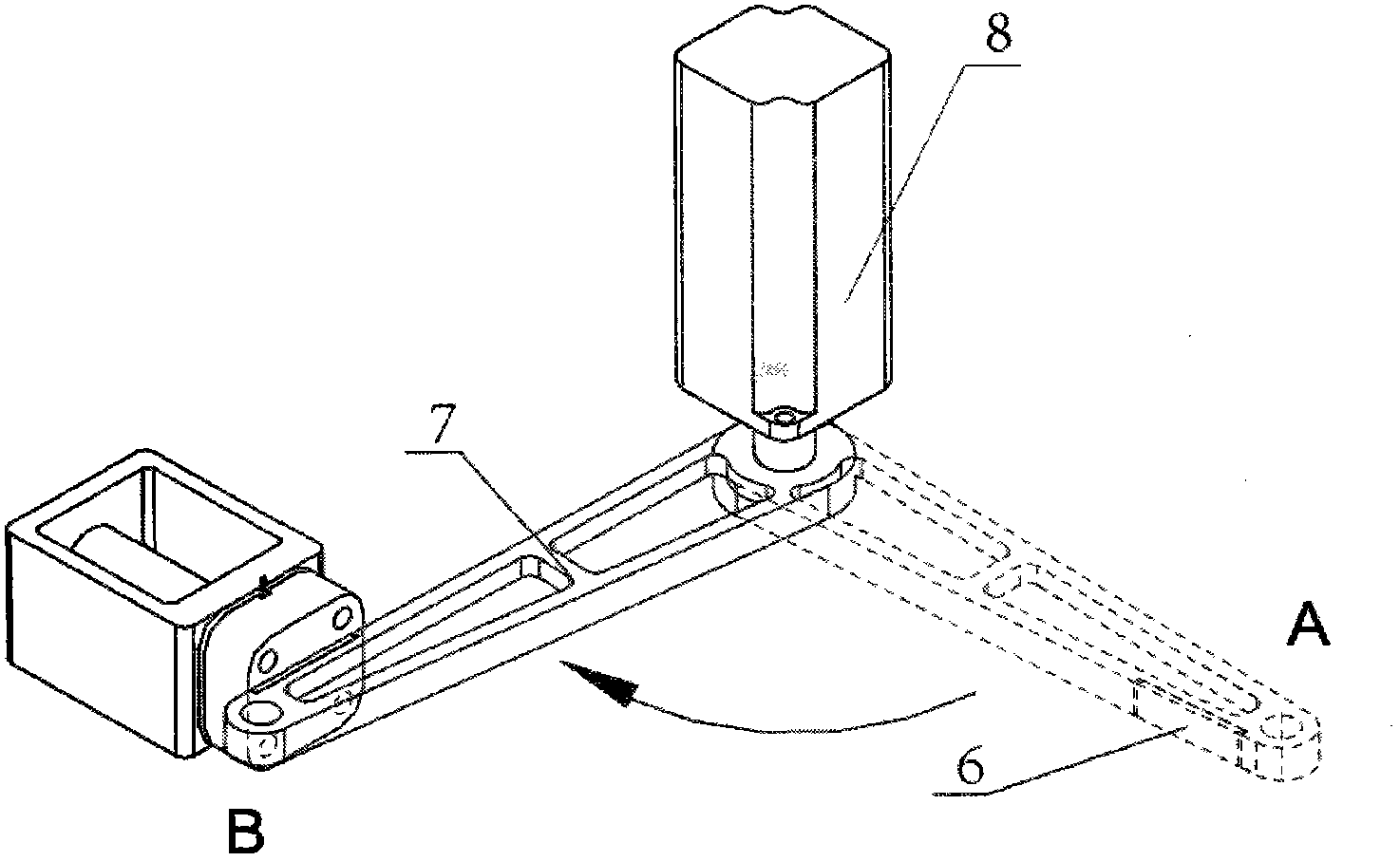

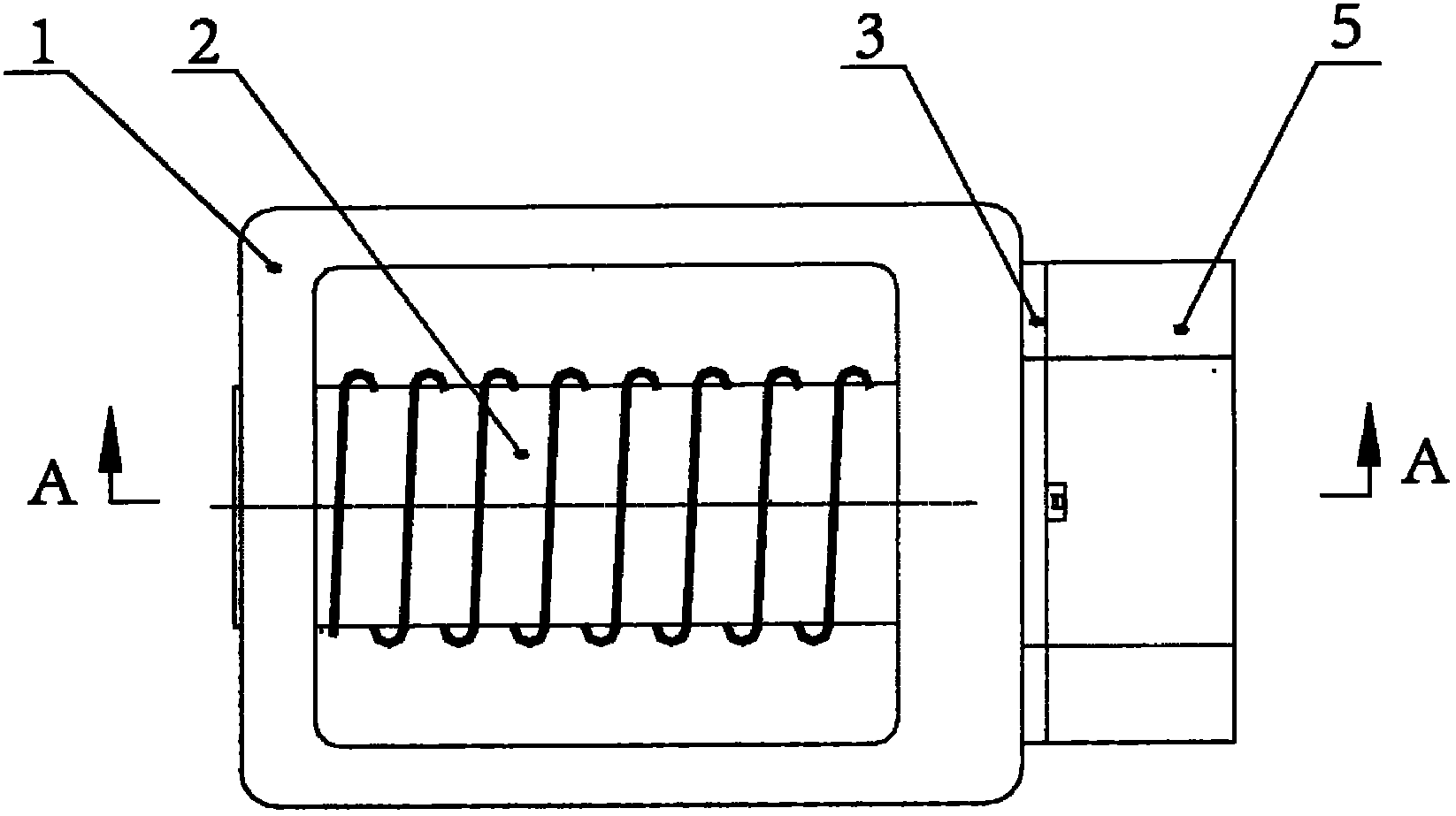

[0027] The structure diagram of the present invention is as figure 1 and figure 2 As shown, the device of the present invention is mainly composed of a housing (1), an electromagnet (2), a support plate (3), a strain gauge (4), an elastic body (5) and an armature (6). Wherein the electromagnet (2) is fixed inside the casing (1), and the support plate (3) and the elastic body (5) are fixed together with the casing (1). Wherein the elastic body (5) has a concave cavity near the electromagnet (2), and the above-mentioned strain gauge (4) is pasted on the middle surface of the concave cavity of the elastic body to directly detect the elastic body Strain, which indirectly detects changes in the pressure an elastomer is subjected to. The armature (6) in the device of the present invention is fixed on the moving part of the main moving device, so that the electromagnetic force of the electromagnet (2) can act on the main moving part.

[0028] Such as figure 2 As shown, the rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com