Control valve set having load maintaining function and buffering vibration-reducing function

A load holding and functional technology, applied in the direction of shock absorbers, shock absorbers, springs/shock absorbers, etc., can solve the problems of no load holding function, bulky buffer mechanism, and inability to install construction machinery, etc., and achieve good technical characteristics , Improve the effect of integration and volume improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

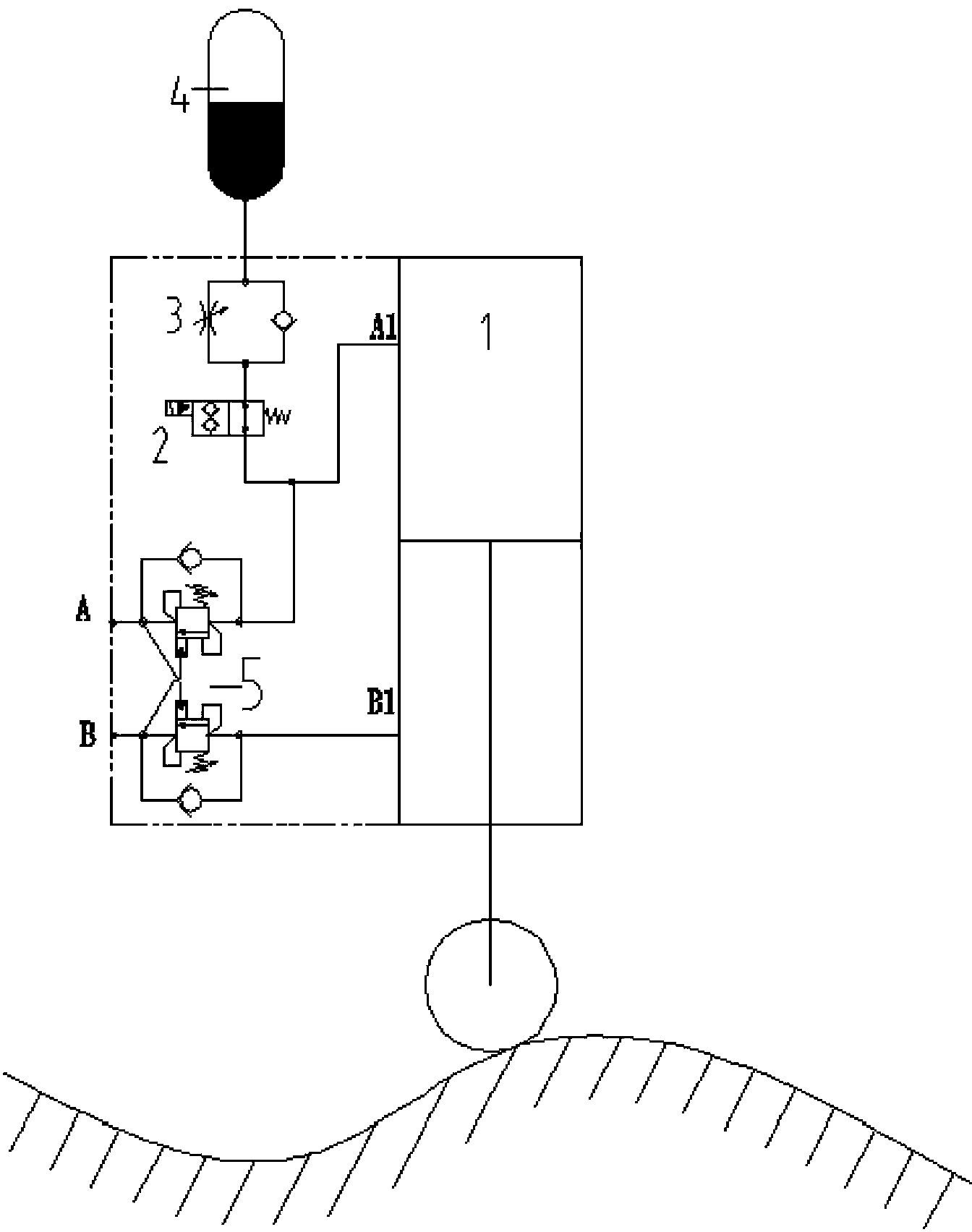

[0011] refer to figure 1 , the control valve group with the functions of load holding and buffering and vibration reduction, including a supporting cylinder 1, a wheel track switching circuit balance valve 5, a two-position four-way solenoid valve 2, a one-way throttle valve 3 and an accumulator 4, the supporting One end of the high-pressure chamber A1 of the oil cylinder 1 is connected in parallel with a first oil circuit and a second oil circuit. The first oil circuit with the buffering and vibration reduction function, the high-pressure chamber A1 of the support cylinder 1, the two-position four-way solenoid valve 2, the one-way throttle valve 3 and the accumulator 4 are sequentially connected through oil pipes; the support cylinder The high-pressure chamber A1 of 1, the wheel-shoe switching circuit balance valve 5, and the low-pressure chamber B1 of the supporting cylinder 1 constitute the second oil circuit with load protection function, and the oil outlet of the high-pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com