Infrared burner of stainless steel metal corrugated plate

A technology of infrared burner and metal corrugated plate, which is applied in the direction of burner, gas fuel burner, combustion method, etc., can solve the problems of ceramic plate bursting, complicated manufacturing process, incomplete combustion, etc., and achieves unbreakable, simple process, compact effect

Inactive Publication Date: 2013-09-04

杨斌

View PDF1 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] As we all know, most of the gas cookers on the market currently use atmospheric burners, and all combustion depends on the mixing of secondary air, which has the disadvantages of low thermal efficiency and large exhaust emissions. However, due to the unique heating method and good energy-saving effect of infrared gas cookers, It has attracted people's attention. Over the years, most infrared gas cookers have used ceramic materials to make heating plates. The stability of ceramic plates is poor, and the manufacturing process is relatively complicated. Over time, the ceramic plates may burst and weather, which will cause gas cookers. The fire cannot be used normally, this phenomenon seriously restricts the development of infrared gas cookers. In order to solve this problem, in recent years, metal fiber materials, wire mesh and metal foam boards have also been used to make infrared burners, but the effects are not good. ideal

[0003] The Chinese invention patent "foam metal heating plate for infrared burner" (patent number: 201010562502.5; announcement number: CN102003709A) discloses the content of using foam metal plate to make infrared heater, which solves the problem that the ceramic plate material is easy to break, but still The production process is complicated, the pore size of the foam metal plate is difficult to control accurately, and it is easy to block, and the phenomenon of incomplete combustion will occur after a long time of use

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0021] Below by embodiment, the present invention will be further described in conjunction with accompanying drawing;

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

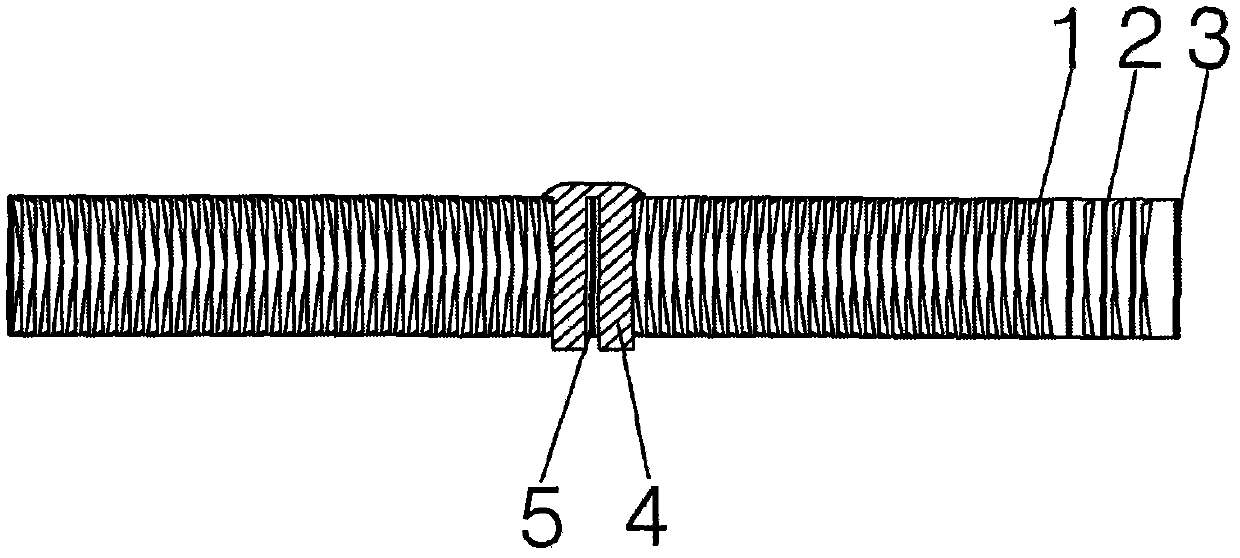

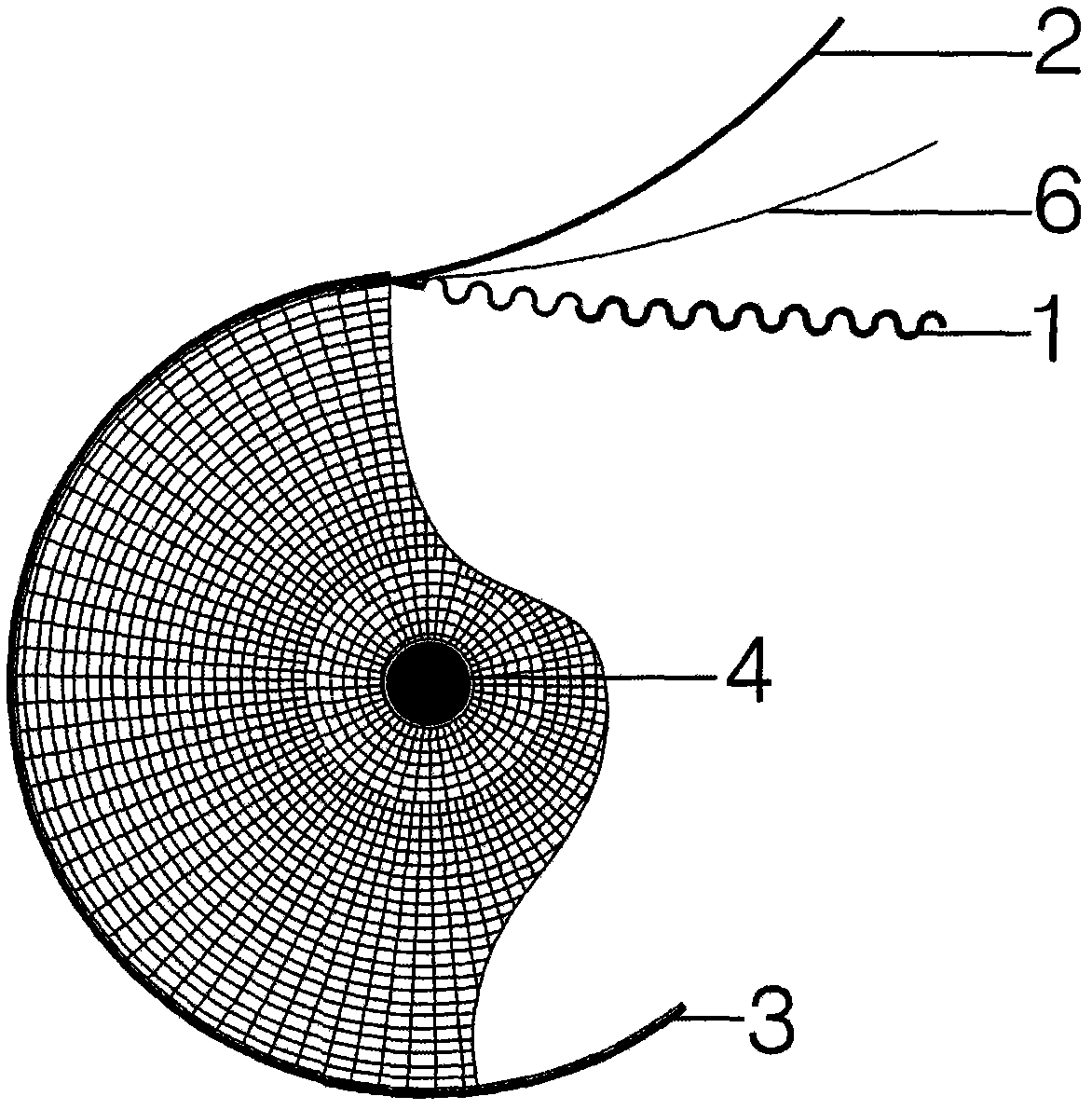

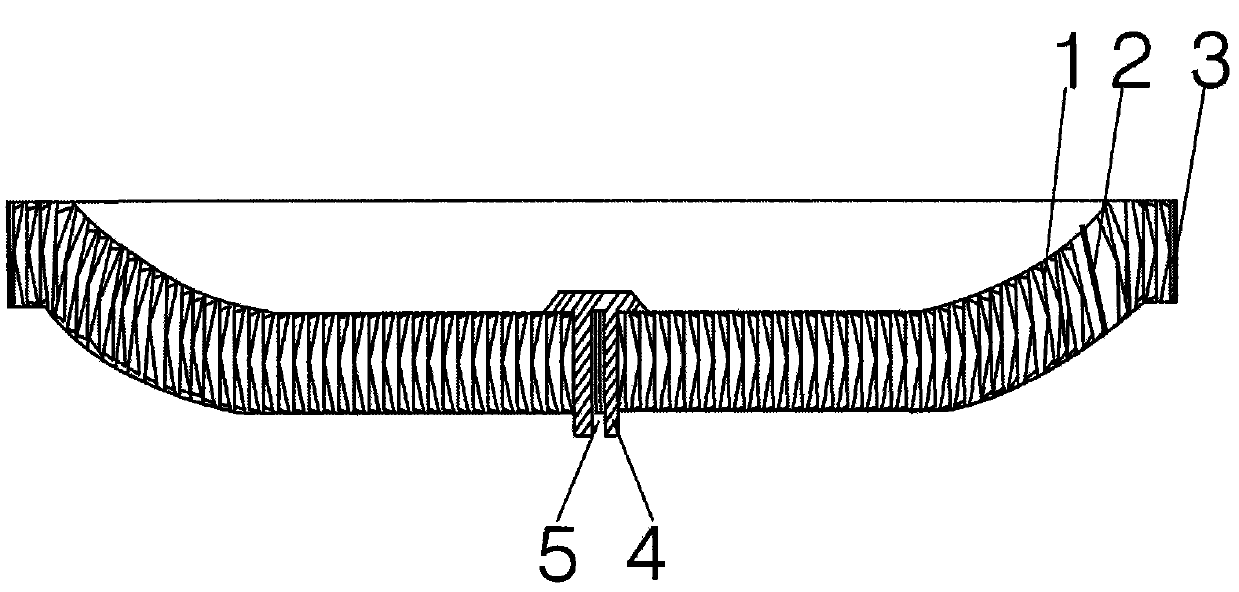

The invention discloses an infrared burner of a stainless steel metal corrugated plate. According to the infrared burner of the stainless steel metal corrugated plate, a metal corrugated belt, a welding film belt and a metal belt are mainly wound on a center shaft in an uniformly-level mode or arranged to form a square or a rectangle, and a metal ring is arranged on the outer layer in order to fix the metal corrugated belt, the welding film belt and the metal belt. By means of high temperature brazing, the welding film belt is melted, and the metal corrugated belt and the metal belt are welded into a whole to form a burning hole. With regard to the shape, the infrared burner of the stainless steel metal corrugated plate can be made into a plane shape or a combination of a plane and a curved surface or a curved surface, so that requirements for various purposes are met. With the regard to the technology, the infrared burner of the stainless steel metal corrugate plate is simple in structure, good in stability and not prone to being broken.

Description

technical field [0001] The invention relates to a burner, in particular to a stainless steel metal corrugated plate infrared burner. Background technique [0002] As we all know, most of the gas cookers on the market currently use atmospheric burners, and the combustion all depends on the mixing of secondary air, which has the disadvantages of low thermal efficiency and large exhaust gas emissions. However, due to the unique heating method and good energy-saving effect of infrared gas cookers, It has attracted people's attention. Over the years, most infrared gas cookers have used ceramic materials to make heating plates. The stability of ceramic plates is poor, and the manufacturing process is relatively complicated. Over time, the ceramic plates may burst and weather, which will cause gas cookers. The fire cannot be used normally, this phenomenon seriously restricts the development of infrared gas cookers. In order to solve this problem, in recent years, metal fiber materi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F23D14/14B21C37/087

Inventor 杨斌

Owner 杨斌

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com