Composite core rod torsion tester

A technology of torsion testing machine and composite mandrel, which is applied in the direction of measuring devices, instruments, scientific instruments, etc. It can solve the problems of sample mandrel rotation or axial slippage, lower test accuracy, and failure to clamp, etc., to achieve clamping Unique and reliable holding mechanism, broadened test range, simple and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

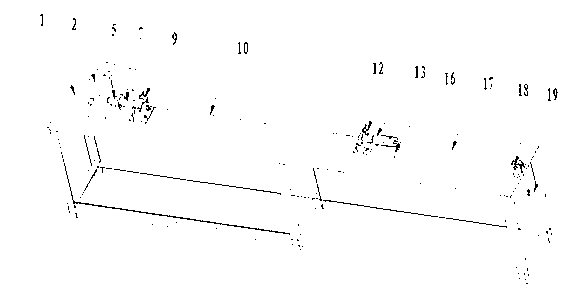

[0019] see figure 1 , the reducer 2, the front clamping assembly, the rear clamping assembly and the pulley assembly 18 of the composite mandrel torsion testing machine of the present invention are connected with the workbench 1 through bolts 11; the reducer 2 and the front clamping assembly are connected through the coupling sleeve 5 The rear clamping assembly and the weight 19 are connected by the rope 17 through the pulley assembly 18; the sample mandrel 10 is clamped and positioned by the front clamping assembly and the rear clamping assembly; the V-shaped block 16 supports the rear clamping assembly.

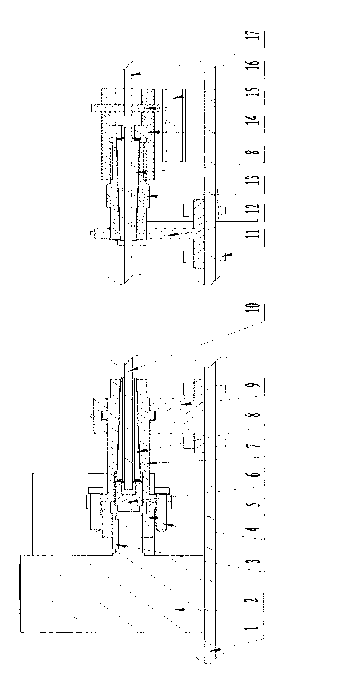

[0020] Such as figure 2 As shown, before starting the torsion test of the composite mandrel, make sure that the power supply is in the off state; Clamped in the spring sandwich core 8; put them into the front bracket 9 and the rear bracket 12 respectively and fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com