Color-coated sheet wiping apparatus

A color-coated plate and wiping head technology, which is applied in the detection field, can solve problems such as very large detection accuracy errors, and achieve the effects of high accuracy, improved stability, and uniform wiping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

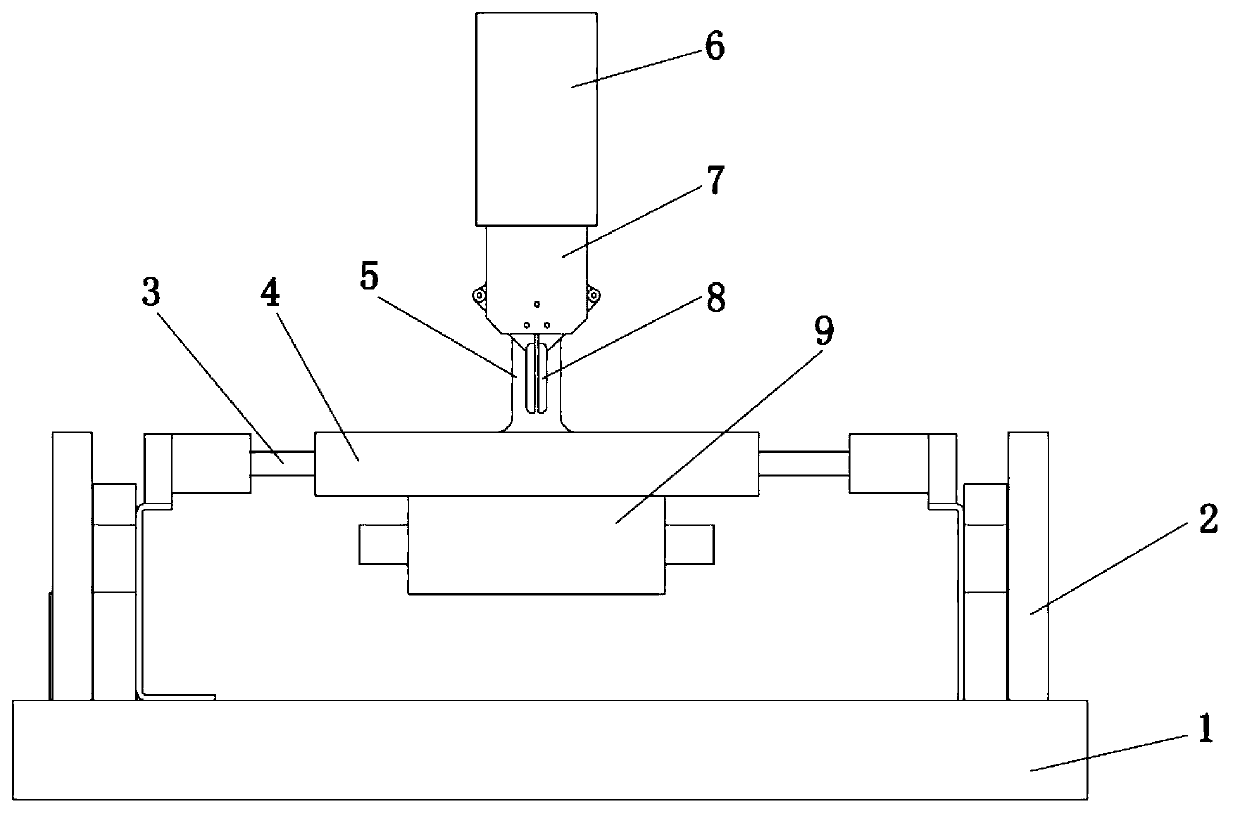

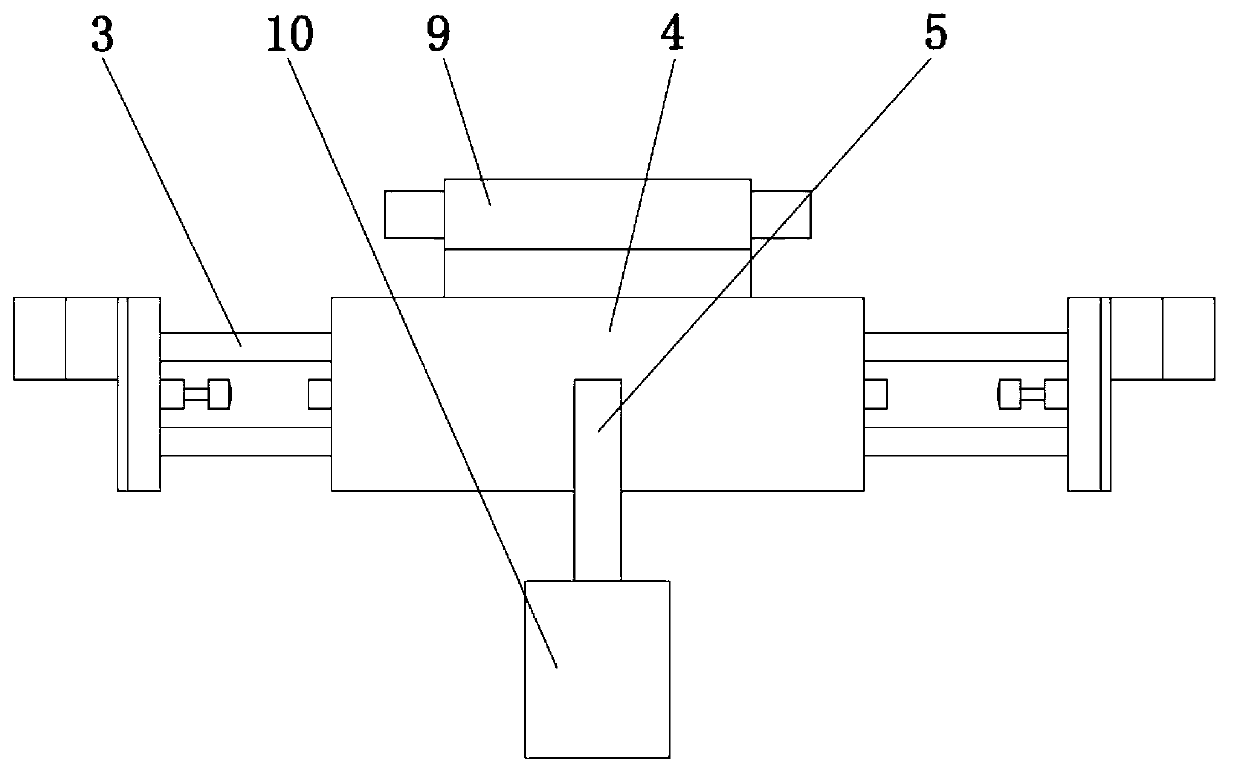

[0015] Such as figure 1 As shown, the wiping instrument is composed of a base 1, a bracket 2, a slide rail 3, a slider 4, a moving cylinder 9, a clamping cylinder 7, a wiping head and a wiping table. Support 2 is installed on both sides on the base 1, and slide block 4 is installed on support 2, and slide block 4 is driven by moving cylinder 9, and slide block 4 is installed pillar 5. Wiping head 10 is installed on pillar 5, and wiping head 10 is made of counterweight 6, clamping cylinder 7 and finger 8, and clamping cylinder controls finger to open and close. Below the fingers is the wipe station (not shown).

[0016] Before the wiping work is started, the cotton containing the wiping solution is stuffed into the clamp finger, and the wiping cotton is clamped by clamping the control button. When starting work then, connect the pillar and the slide rail by the connecting piece fixed on the moving cylinder, and the moving cylinder drives the slide block to move back and forth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com