A rapid non-destructive testing method for harvest maturity of flue-cured tobacco

A non-destructive testing and maturity technology, applied in the measurement of color/spectral characteristics, etc., can solve the problems of reducing the curing quality of tobacco leaves, lack of clear quantitative indicators and testing standards, inconsistent harvesting standards, etc., to achieve easy operation and mastery, oil content. Multi-color uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

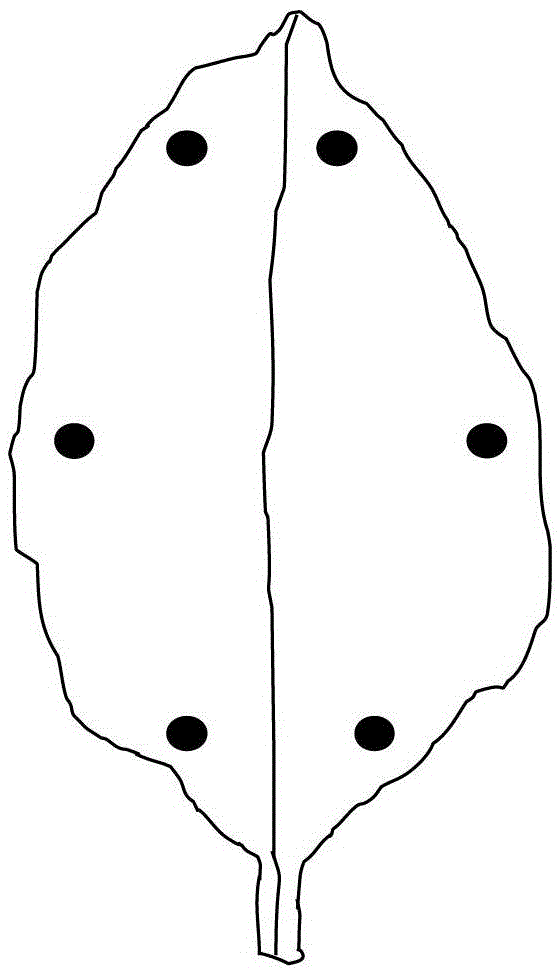

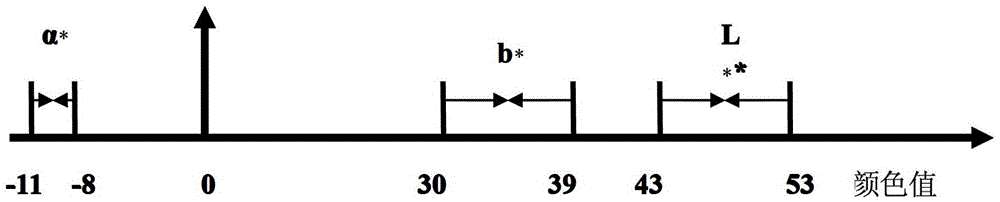

[0016] From 2011 to 2012, the flue-cured tobacco mature harvesting and baking experiment was carried out in the Fuquan Flue-cured Tobacco Base of Guizhou Tobacco Research Institute. In order to accurately judge the maturity of tobacco leaves and clarify the maturity standards of tobacco leaves, random selection was made in the tobacco fields with the same transplanting period and cultivation management measures. For 20 tobacco plants, measure the L*a*b* color value of 1 to 3 tobacco leaves in the middle (from bottom to top) with a portable color difference meter. Each leaf should choose to detect 6 points, that is, the tip, middle and leaf base in the center of the leaves on both sides of the main vein, avoiding the main branch veins of the leaves, and then take the average value. L*a*b* values of the first tobacco leaf: 61.25, -5.12, 45.1; L*a*b* values of the second tobacco leaf: 57.99, -6.91, 44.86; L*a of the third tobacco leaf The values of *b* are: 56.76, -7.32, 42...

Embodiment 2

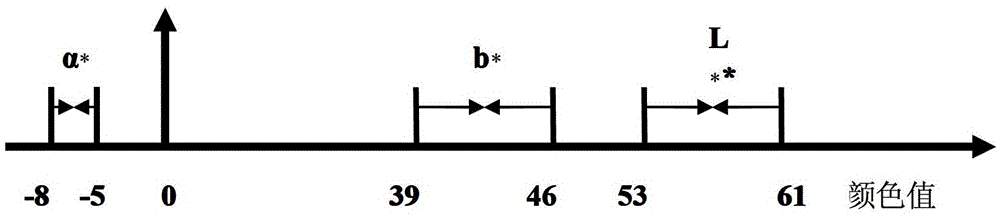

[0018] From 2011 to 2012, the mature harvesting and curing experiment of flue-cured tobacco was carried out in Fuquan Flue-cured Tobacco Base of Guizhou Tobacco Science Research Institute. 20 tobacco plants were randomly selected in a tobacco field with the same transplanting period and cultivation management measures, and the L*C*h* color value of 1 to 3 tobacco leaves in the middle (from bottom to top) was measured with a portable colorimeter. Each leaf should choose to detect 6 points, that is, the tip, middle and leaf base in the center of the leaves on both sides of the main vein, avoiding the main branch veins of the leaves, and then take the average value. L*C*h* values of the first tobacco leaf: 59.6, 46.12, 97.76; L*C*h* values of the second tobacco leaf: 57.99, 45.39, 98.76; L*C*h of the third tobacco leaf The * values are: 56.92, 44.43, 99.8, all within the appropriate range, indicating that 1 to 3 tobacco leaves are mature and can be harvested and roasted at ...

Embodiment 3

[0020] From 2011 to 2012, the mature harvesting and baking experiment of flue-cured tobacco was carried out in Fuquan Flue-cured Tobacco Base of Guizhou Tobacco Research Institute. In the tobacco field with the same transplanting period and cultivation management measures, 20 tobacco plants were randomly selected, and the middle leaves were measured with a portable color difference meter ( From bottom to top) 1 to 3 tobacco leaves L*a*b*C*h*color value. Each leaf should choose to detect 6 points, that is, the tip, middle and leaf base in the center of the leaves on both sides of the main vein, avoiding the main branch veins of the leaves, and then take the average value. The L*a*b*C*h* value of the first tobacco leaf: 61.28, -5.2, 46.39, 46.68, 96.4; the L*a*b*C*h* value of the second tobacco leaf: 59.38, - 5.17, 43.45, 43.76, 96.78; the L*a*b*C*h* value of the third tobacco leaf: 56.84, -6.23, 44.06, 44.5, 98.05, all within the appropriate range, indicating that the tobacco l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com