A Method for Establishing Guideway Slider Database Oriented to Finite Element Analysis of Machine Tool

A technology for a guide rail slider and a method for establishing it, which is applied in the fields of electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of waste of design resources, cumbersome operation, and great influence on the efficiency and stability of finite element analysis of machine tools.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

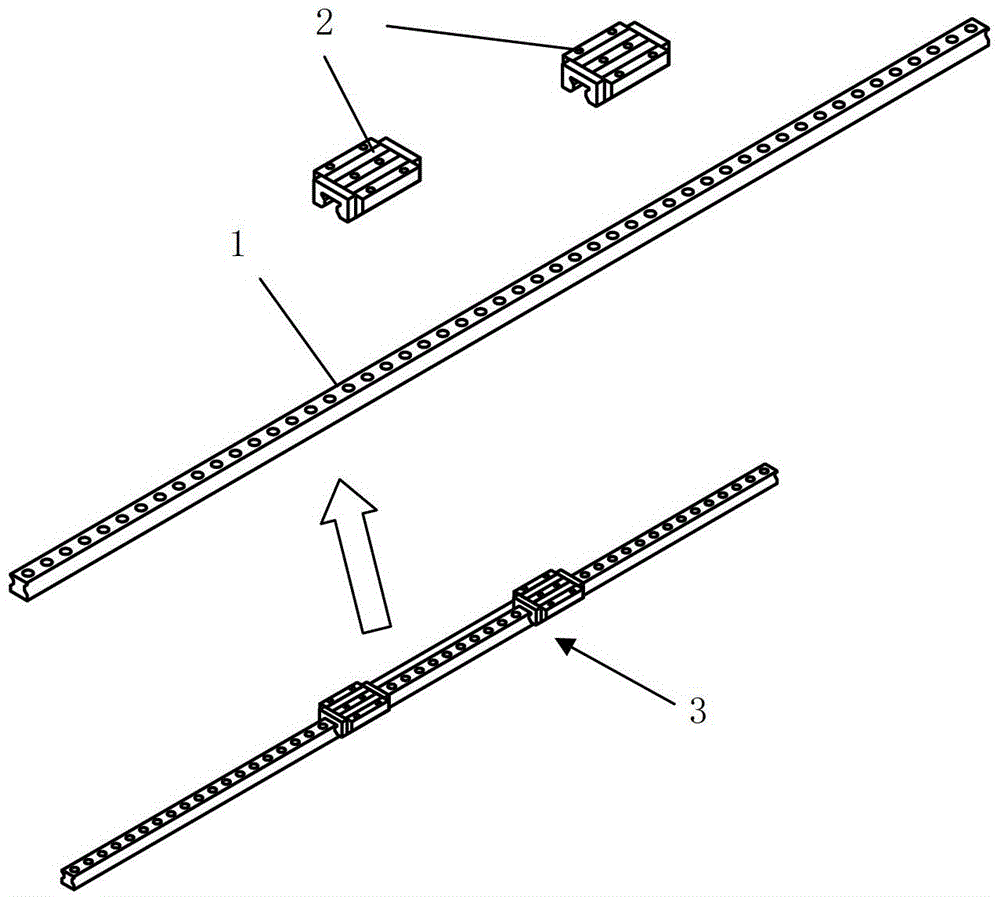

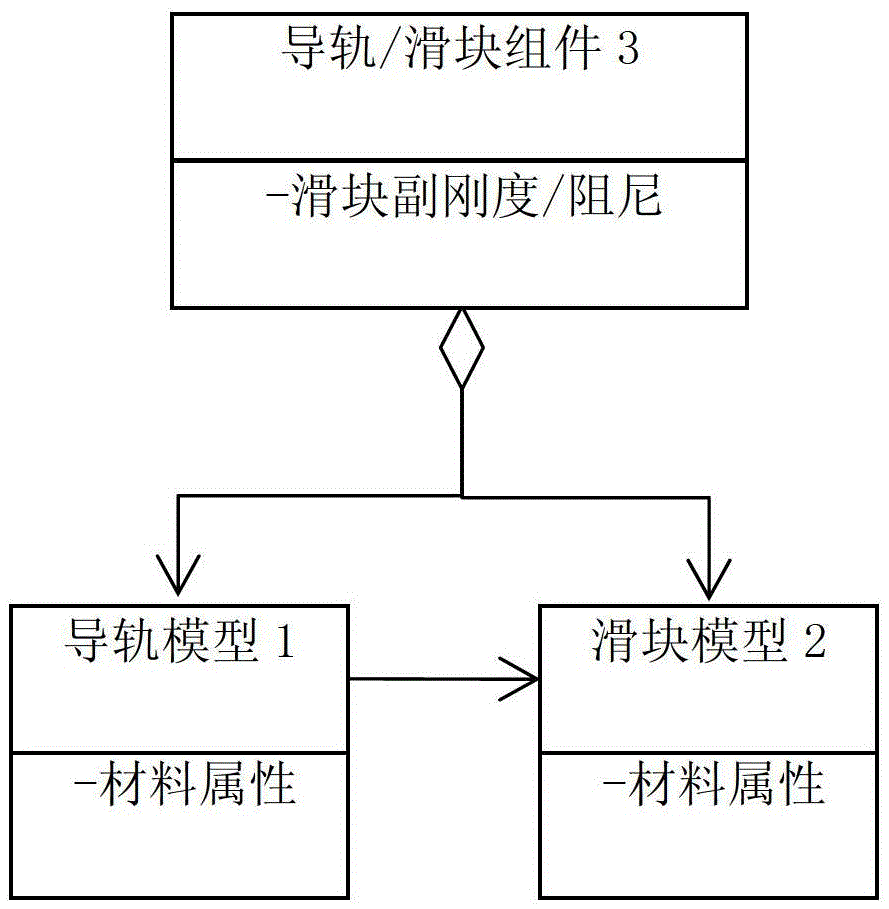

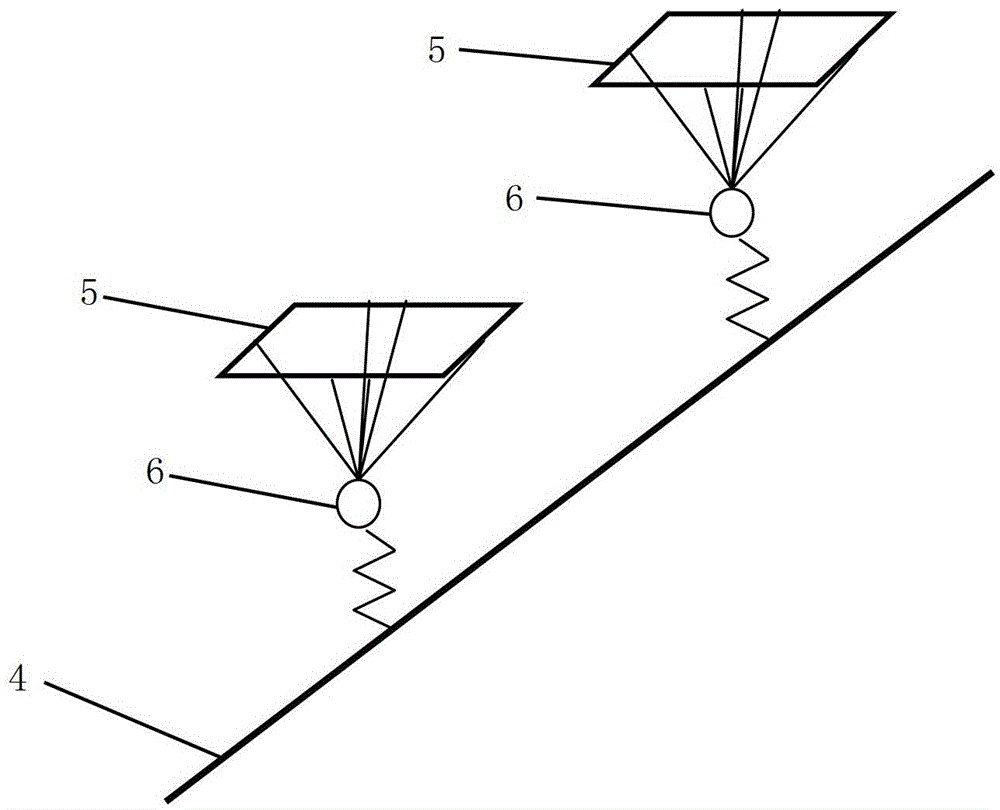

[0034] A method for establishing a guide rail slider database oriented to machine tool finite element analysis according to the present invention will be described in detail below in conjunction with the embodiments and drawings.

[0035] A method for establishing a guide rail slider database oriented to machine tool finite element analysis of the present invention extracts CAD model driving parameters and dynamic analysis parameters according to the supplier's manual, and establishes a database; then establishes CAD parameters of the corresponding guide rail slider assembly according to the database Finally, through the secondary development of CAD and CAE software, the reading of CAD parameters and analysis parameters of the guide rail slider assembly and the automatic creation of the CAE equivalent analysis model are realized.

[0036] A kind of guide rail slider database establishment method facing machine tool finite element analysis of the present invention is characteriz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com