Core valve type reactor

A technology of reactors and iron cores, applied in the direction of inductors with magnetic cores, electromagnets with armatures, electromagnets, etc., can solve the problems of large safety hazards, complex structures, high operating costs, etc. The effect of high reliability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

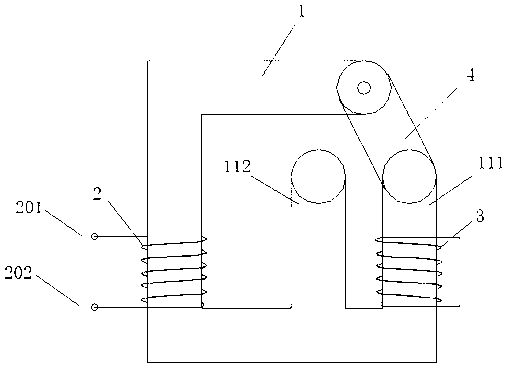

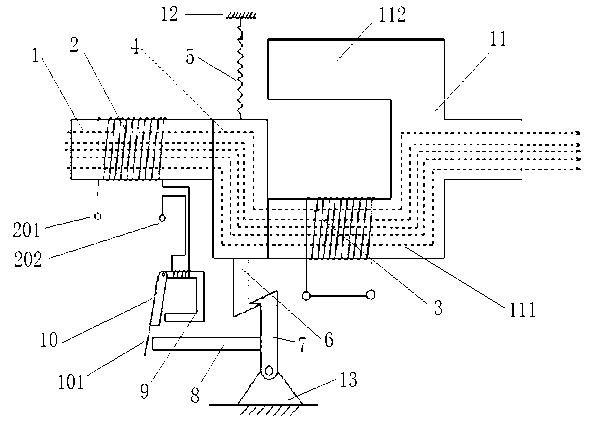

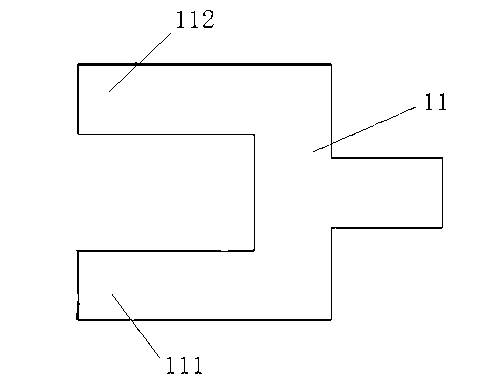

[0034] Such as figure 1 As shown, an iron core valve reactor according to the present invention includes an iron core valve armature arm 4, a main iron core shunt 111, an iron core 1 and a main side reactance winding 2 wound on the iron core 1. The main iron core branch 111 is wound with a short circuit winding group 3, and the main side reactance winding 2 on the iron core 1 is formed by the iron core valve armature arm 4 and the short circuit winding group 3 on the main iron core branch 111. coupling loop. At this time, according to the impedance transformation principle of the ideal transformer 1:1, the impedance of the short-circuit surrounding group 3 on the main iron core shunt 111 is very small and approximately equal to zero...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com