Manufacturing method of thin film transistor (TFT) array substrate and TFT array substrate

A technology of an array substrate and a manufacturing method, which is applied in the field of flat panel display, can solve the problems of long period of reticle design, development and production, high cost, rising production cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to make the purpose, technical solution and advantages of the present invention more clear, the following will be further described in detail in conjunction with the accompanying drawings.

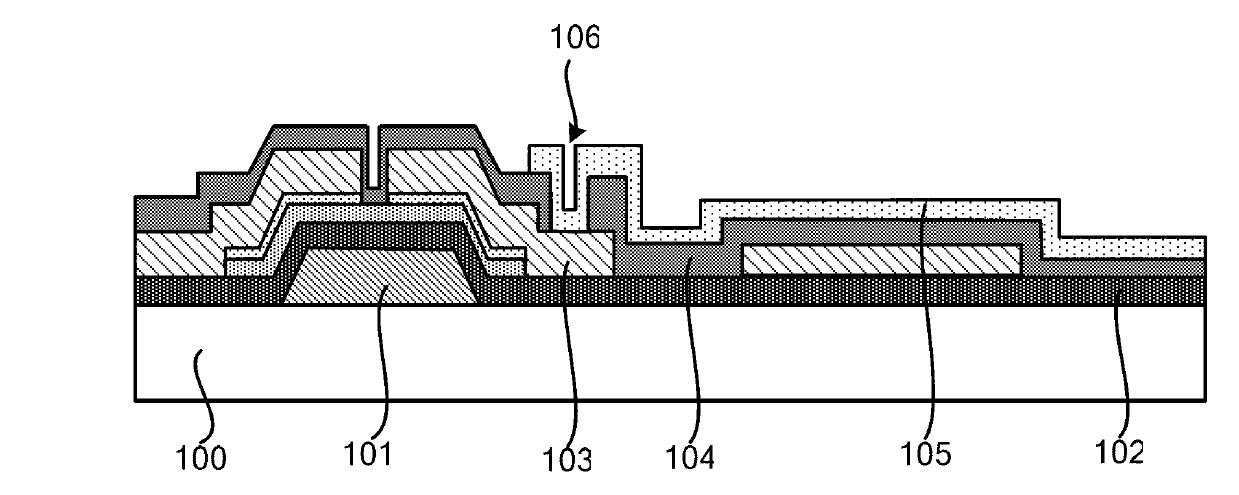

[0051] image 3 It is a top view of a TFT array substrate according to an embodiment of the present invention. Such as image 3 As shown, a TFT array substrate 200 according to an embodiment of the present invention includes a substrate 201 , and the substrate 201 includes a display area 202 and a peripheral area 203 surrounding the display area 202 . A plurality of thin film transistors 204 (Thin Film Transistor, TFT) are included in the display area 203 . Applying an amorphous silicon gate driver integrated with an active matrix (amorphous silicon gate, ASG) technology, a gate drive circuit 205 is provided in the peripheral area 203, and the gate drive circuit 205 can be used to replace a gate drive IC, so that the display becomes lighter.

[0052] Attached below Fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com