Method for temporarily wiring 35kV medium voltage cables for narrow space

A temporary wiring, narrow ground technology, applied in the direction of connecting/terminating cables, etc., can solve the problems of narrow space, difficult wiring of high-voltage terminals, damaged cable ends, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

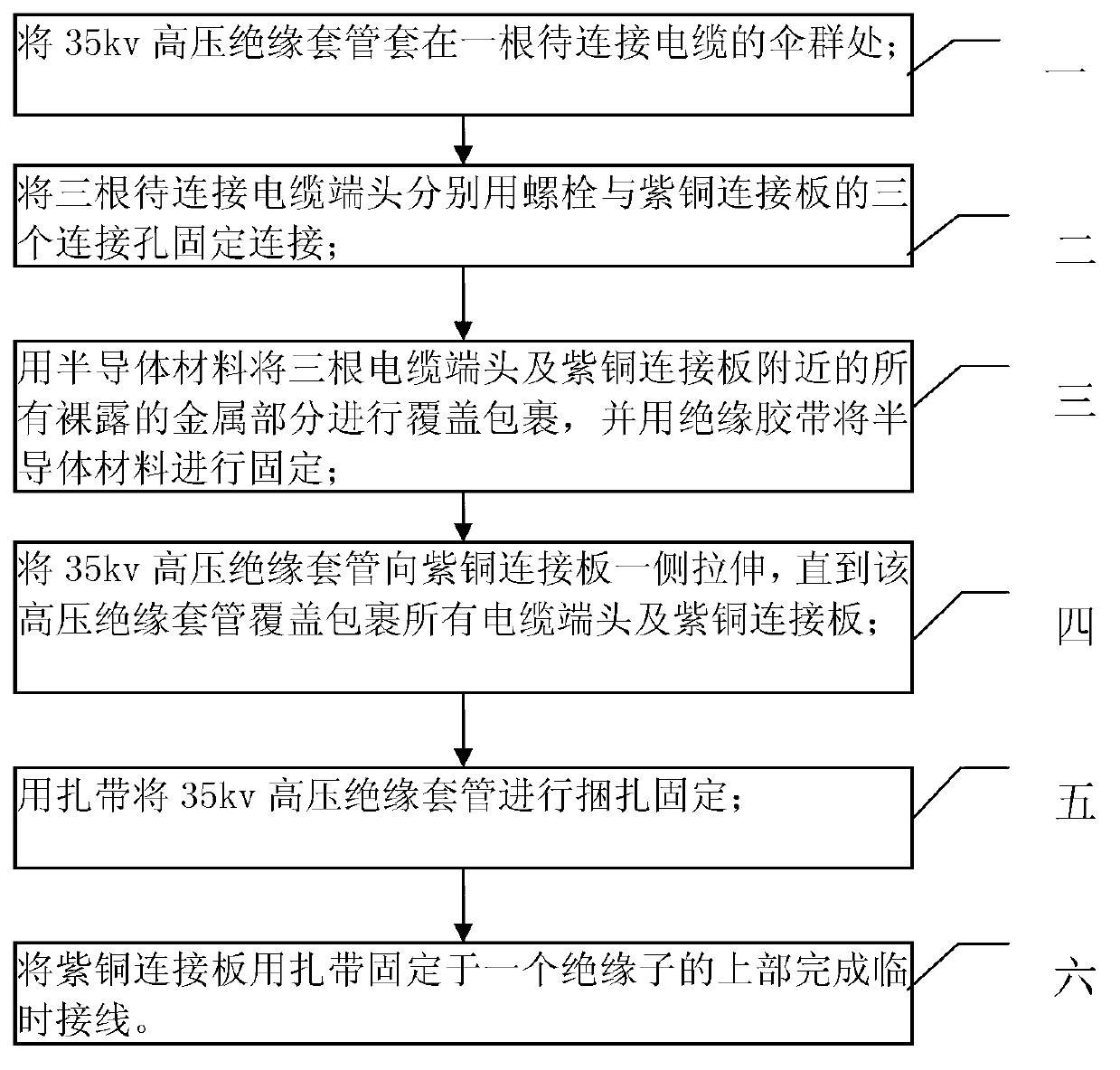

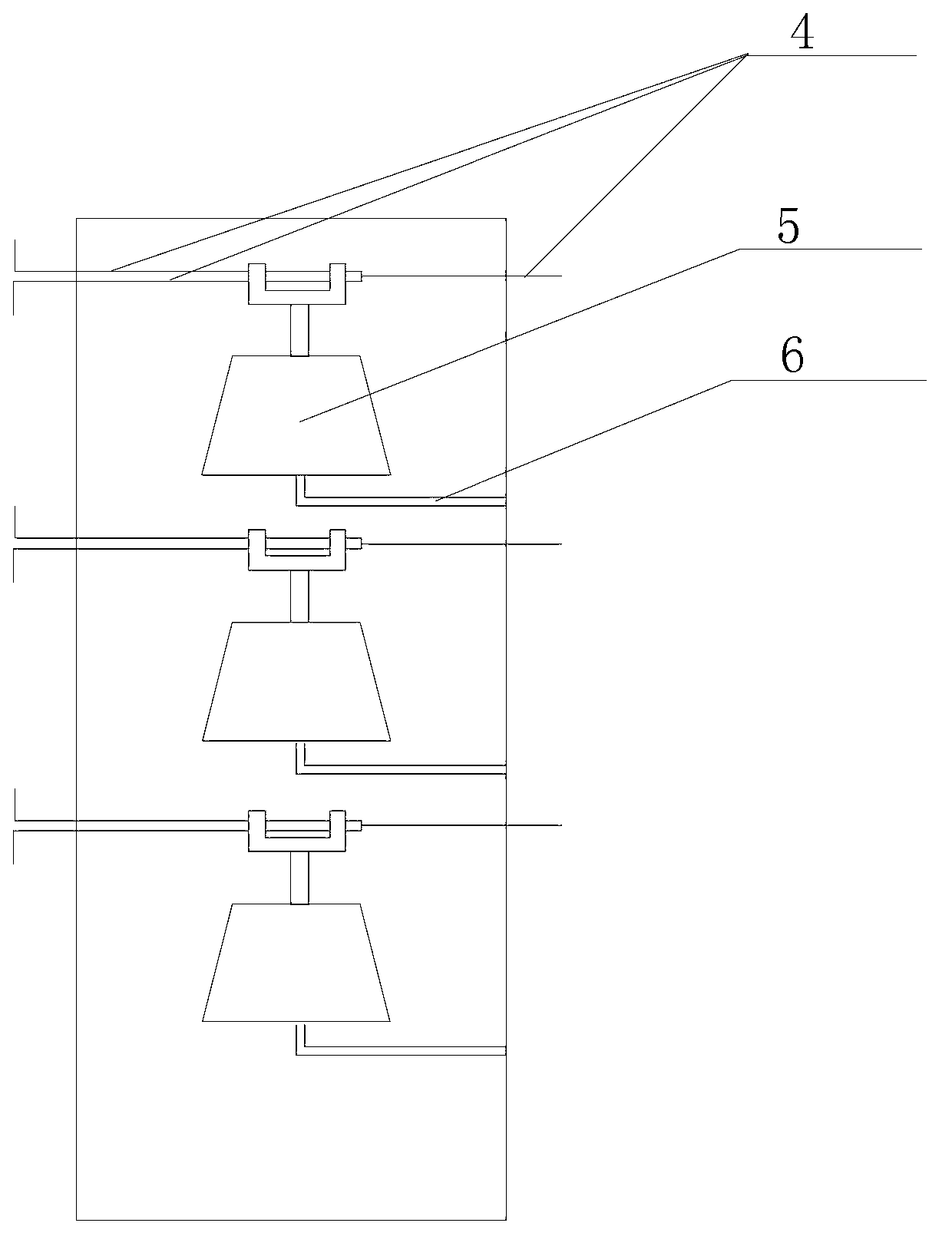

[0018] Specific implementation mode one: see figure 1 , figure 2 and Figure 4 Describe this embodiment, a temporary connection method for 35kV medium-voltage cables used in narrow places described in this embodiment. Steel frame 6, three insulators 5 are arranged on the supporting steel frame 6, the temporary wiring method of each phase cable is the same, and the wiring method of one phase cable is:

[0019] Step 1: Put the 35kv high-voltage insulating sleeve 1 on an umbrella group of cables to be connected;

[0020] Step 2: Fix and connect the three cable ends 4 to be connected to the three connection holes of the copper connecting plate 3 with bolts;

[0021] Step 3: Cover and wrap all the exposed metal parts near the three cable ends 4 and the copper connecting plate 3 with the semiconductor material 2, and fix the semiconductor material 2 with insulating tape;

[0022] Step 4: Stretch the 35kv high-voltage insulating sleeve 1 toward the copper connecting plate 3 unti...

specific Embodiment approach 2

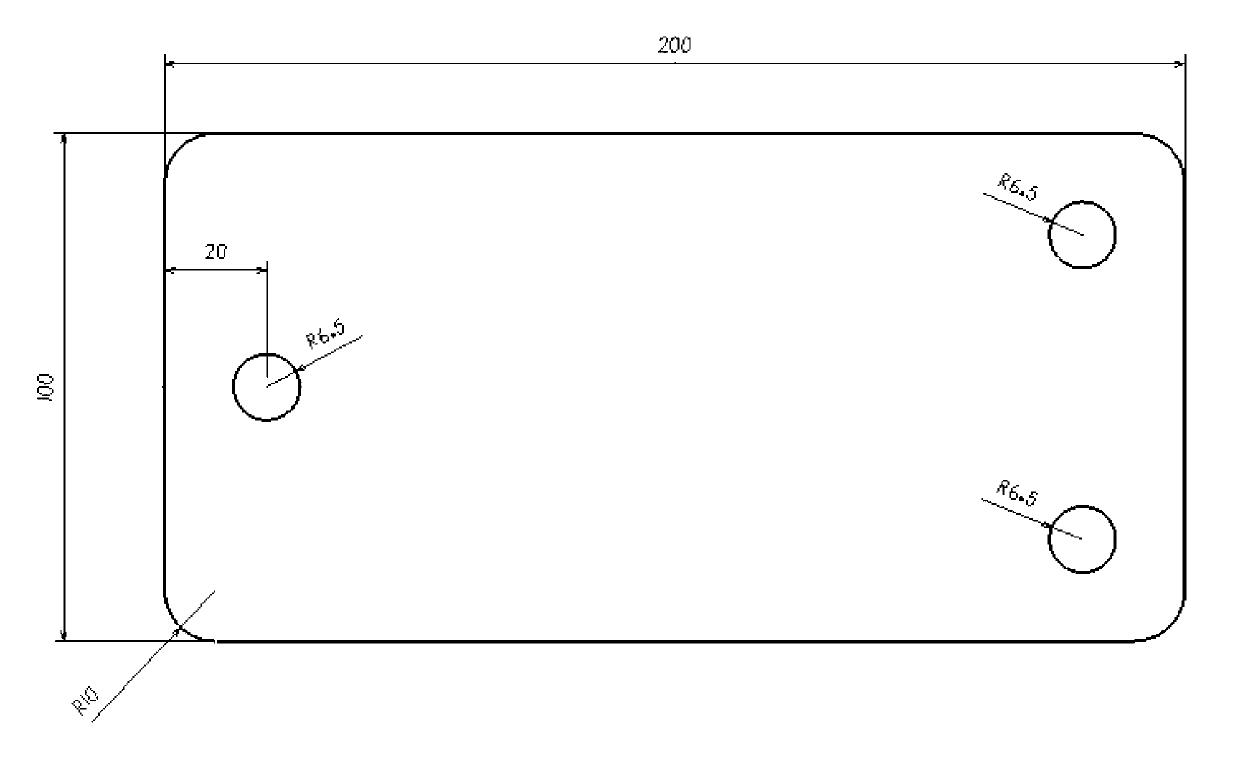

[0028] Specific embodiment 2: This embodiment is a further limitation of the temporary wiring method for 35kV medium voltage cables in narrow places described in specific embodiment 1. The copper connecting plate 3 in the step 2 is 180mm to 100mm long. 210mm, a copper plate with a width of 80mm to 110mm and a thickness of 6mm to 9mm.

specific Embodiment approach 3

[0029] Specific implementation mode three: see image 3 Describe this embodiment, this embodiment is a further limitation of a temporary connection method for 35kV medium-voltage cables in a narrow place described in the second embodiment, the copper connecting plate 3 in the second step is 200mm long, A copper plate with a width of 100mm and a thickness of 8mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com