Reducing agent aqueous solution mixing device and exhaust gas after-treatment device

A technology of mixing device and aqueous solution, which is applied in the direction of exhaust gas treatment, mixer, noise reduction device, etc., can solve problems such as insufficient ammonia, achieve the effects of suppressing back pressure, suppressing the increase of fuel consumption rate, and reducing flow path resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] [the whole frame]

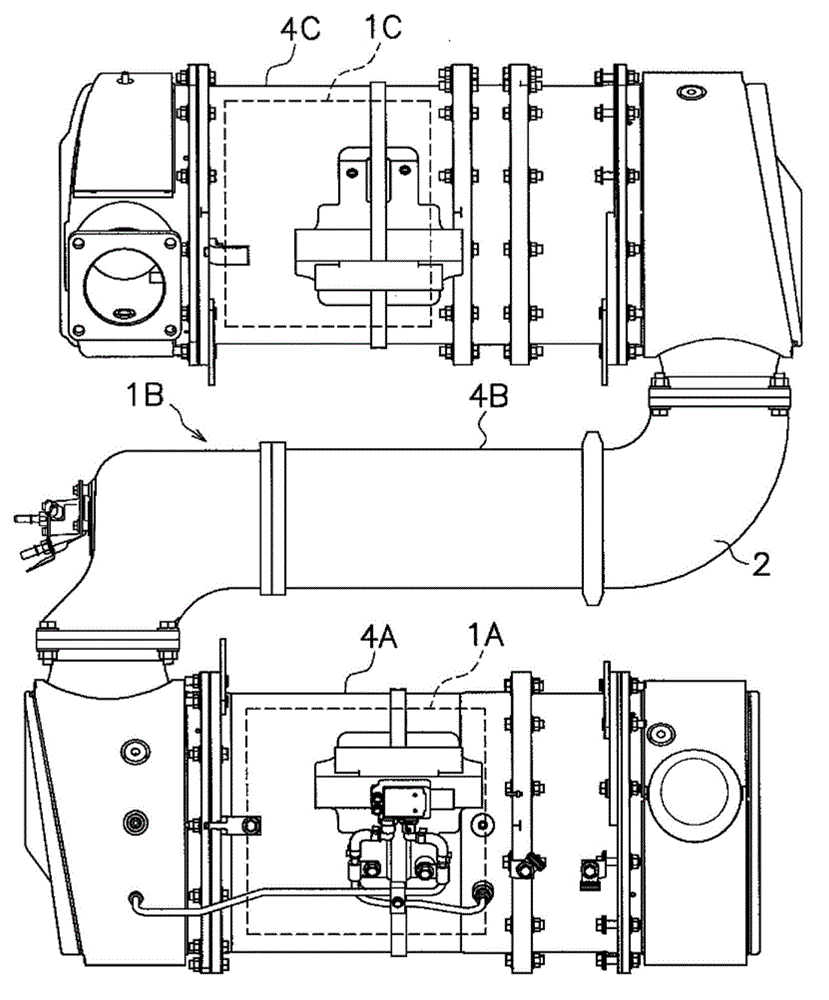

[0056] figure 1 It is a configuration diagram of the exhaust gas post-processing device 1 according to one embodiment of the present invention. The exhaust gas aftertreatment device 1 is sequentially provided with a diesel particulate filter (Diesel particulate filter: hereinafter referred to as "DPF") 1A, a urea aqueous solution mixing device 1B and Nitrogen oxide reduction catalyst (hereinafter referred to as "SCR") 1C. Each of the above-mentioned devices is installed in the middle of an exhaust pipe, and exhaust gas discharged from a diesel engine (not shown) through an exhaust manifold flows through the exhaust pipe.

[0057] DPF1A is a device for trapping particulate matter in exhaust gas, and is housed inside casing 4A.

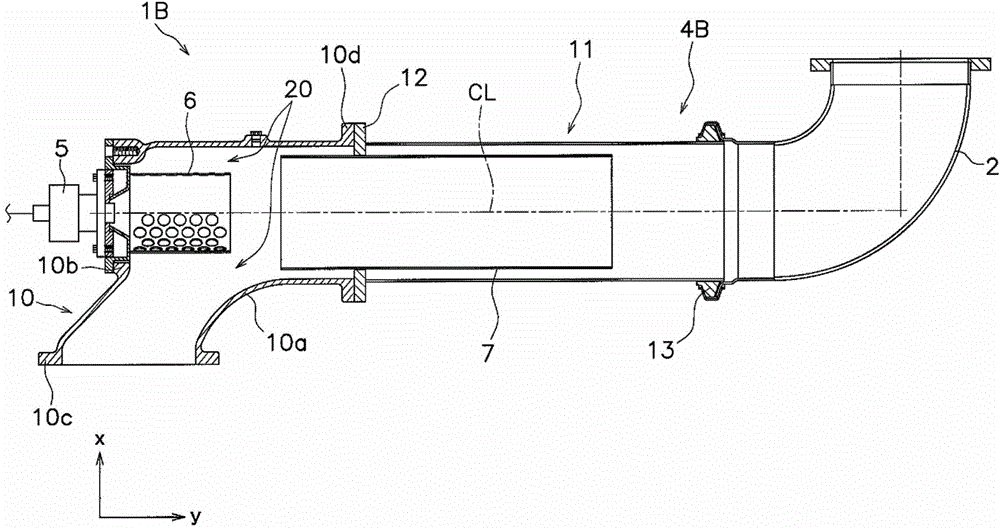

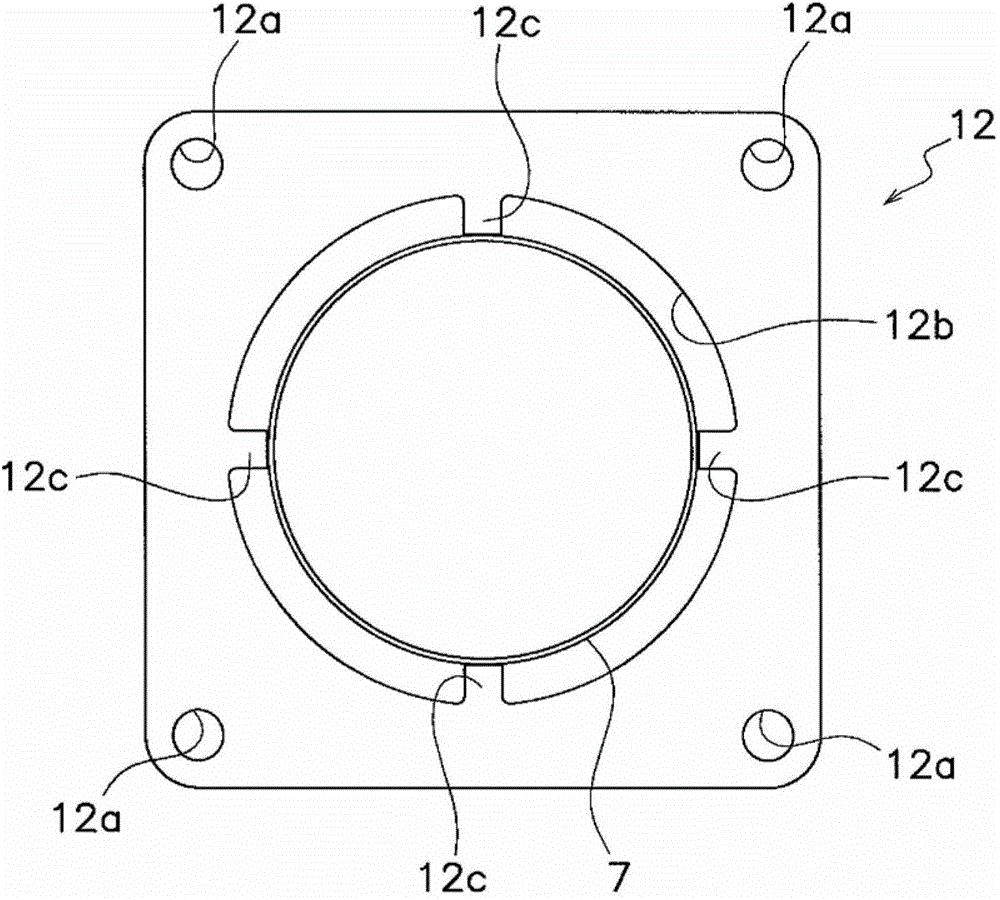

[0058] The urea aqueous solution mixing device 1B is a device for adding an aqueous urea solution as a reducing agent to exhaust gas. The added urea aqueous solution is hydrolyzed to become ammonia, and the ammonia is supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com