Swiss roll type gas-water separator and gas-water separation method

A gas-water separator and channel separator technology, which is applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve the problems of complex structure of gas-water separators and poor separation methods, and improve the performance of gas-water separators. Separation effect, effect of improving adaptability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

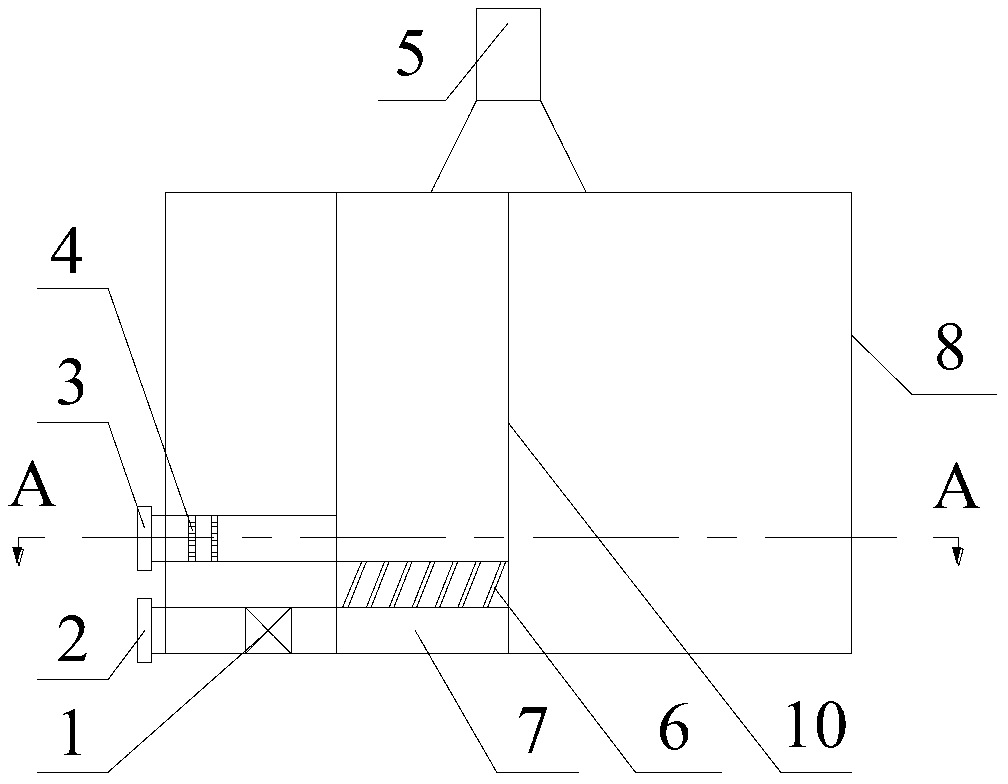

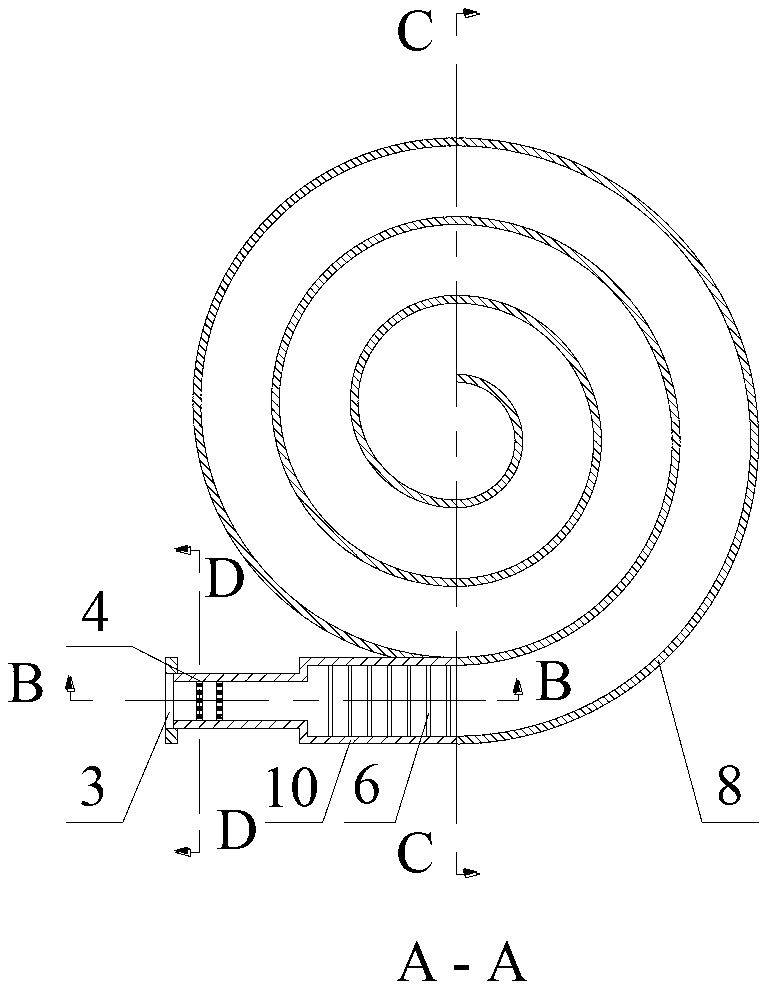

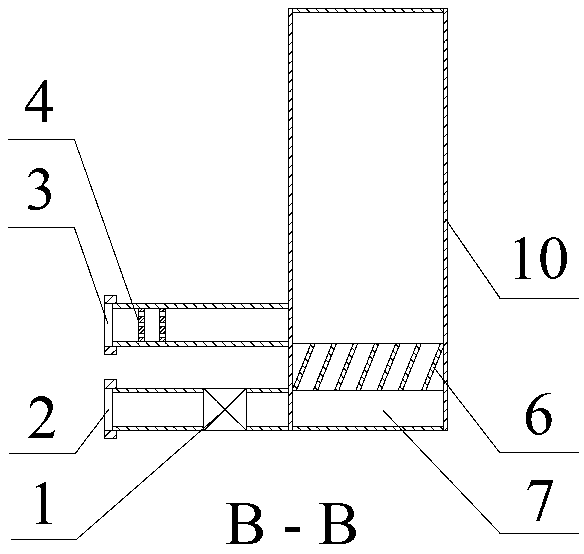

[0021] As shown in the accompanying drawings, the Swiss roll air-water separator of the present invention is mainly composed of an air inlet pipe 3, a drain pipe 2, a water storage bin 7, and a Swiss roll channel separator, and the Swiss roll type channel separator is composed of a spiral Shaped reel 8 and square box 10 connected to the open end of spiral reel 8 constitute, and the number of spiral turns of described helical reel 8 is 3-5 circles. The top of the Swiss roll channel separator is provided with an exhaust pipe 5, the lower part of the square box 10 is provided with an air intake pipe 3 and a drain pipe 2, and between the air intake pipe 3 and the drain pipe 2 is fixed in the square box 10 The water filter plate 6 is provided with a plurality of inclined water guide plates at intervals on the water filter plate 6, and the water guide plates comm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com