Power mixing machine

A technology of power mixing and chain transmission mechanism, applied in the field of machinery, can solve the problems of poor dispersion ability, low efficiency, unable to meet the requirements of high dispersion of materials, etc., and achieve the effect of improving the mixing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The embodiment of the present invention provides a dynamic mixer, which can effectively improve the mixing rate.

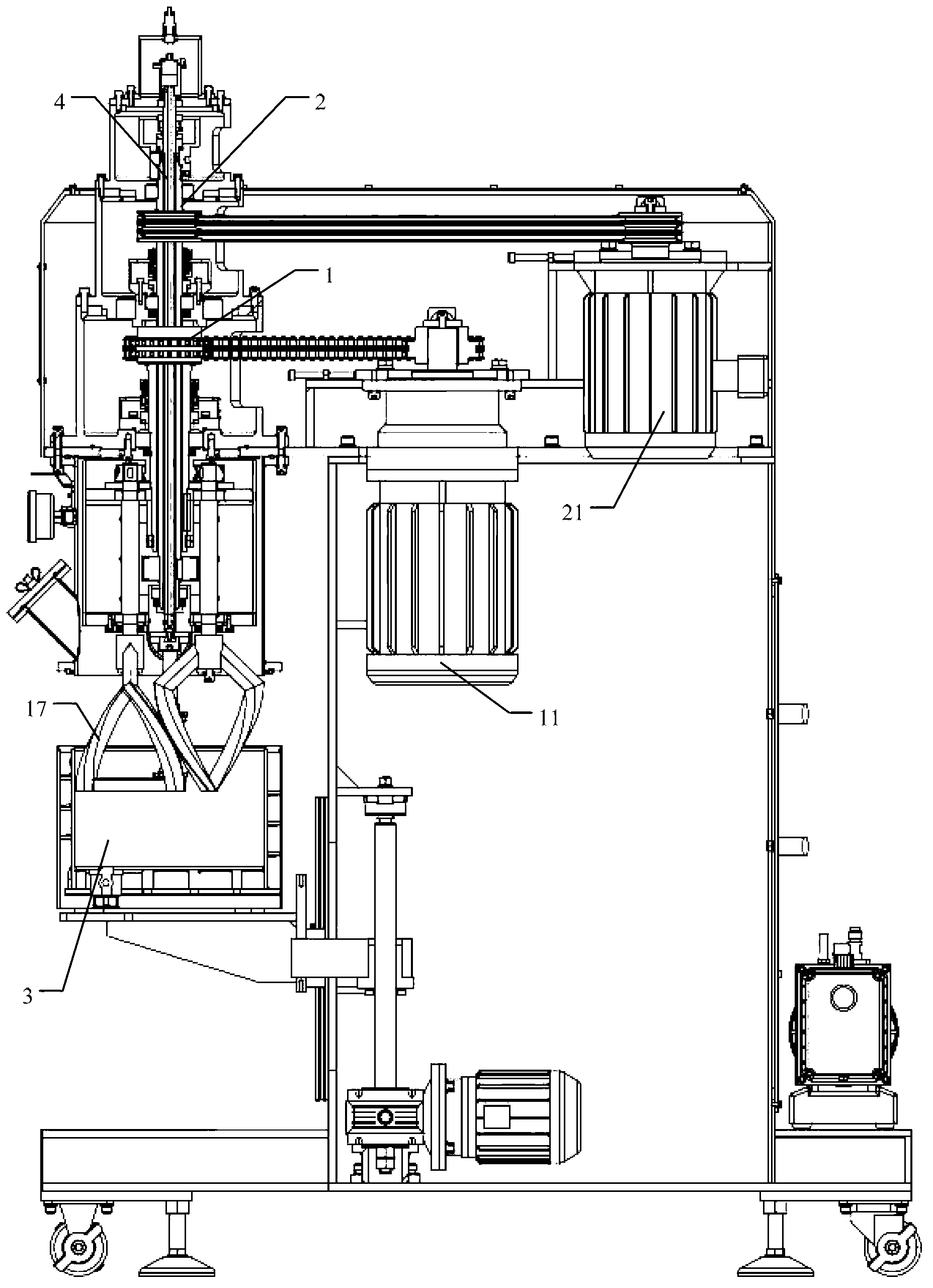

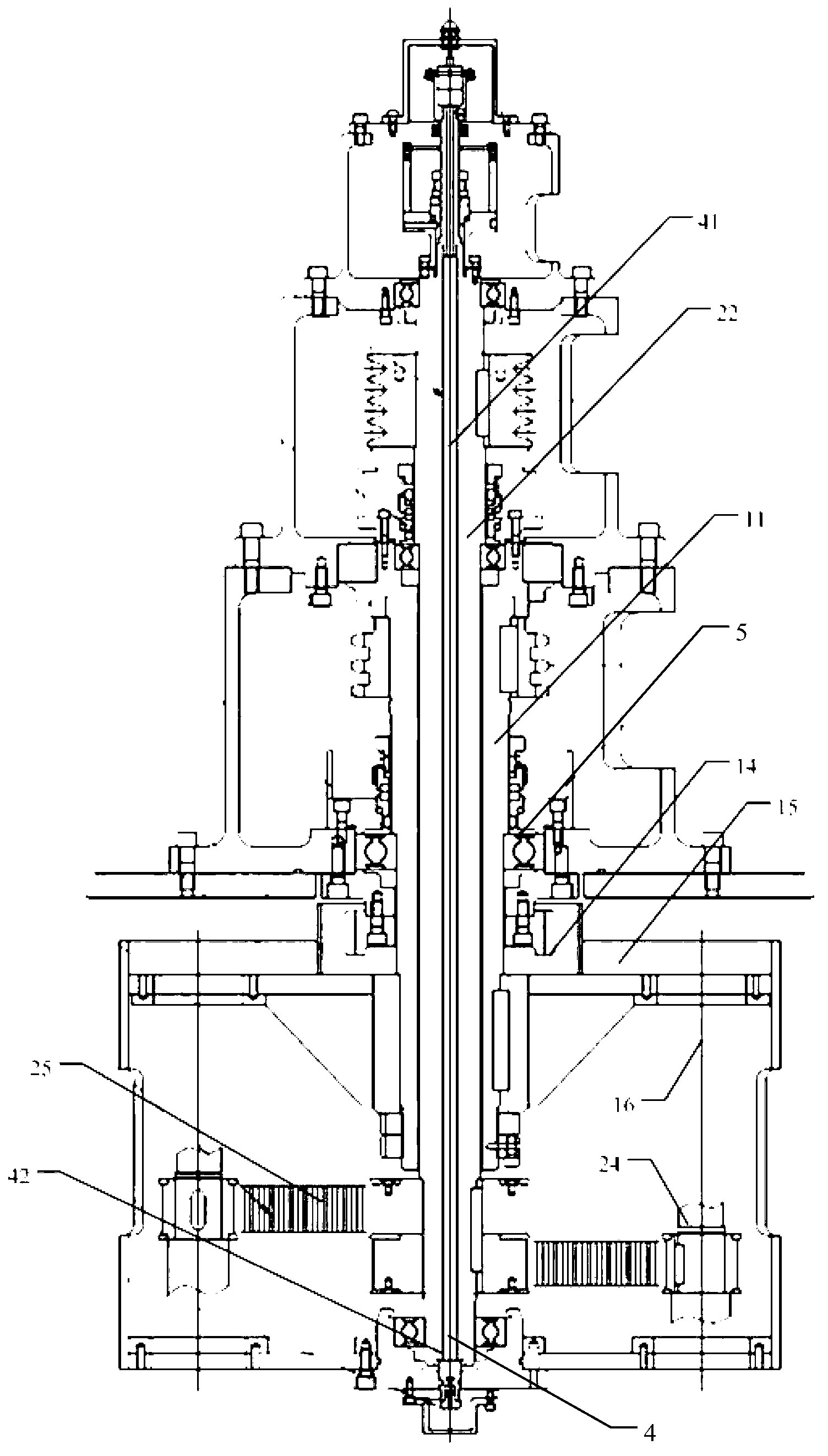

[0057] see figure 1 and figure 2 , an embodiment of a power mixer provided in an embodiment of the present invention specifically includes:

[0058] Power mixing structure 1, high-speed dispersion structure 2 and material tank container 3;

[0059] Power hybrid structure 1 includes:

[0060] Stirring motor 11, mixing main shaft 12, chain transmission mechanism 13, planetary gear mechanism 14, planet carrier 15, at least two planetary shafts 16 and at least two stirring components 17;

[0061] The stirring motor 11 is connected to the mixing main shaft 12 through a chain transmission mechanism 13;

[0062] The planetary gear mechanism 14 and the planet carrier 15 are fixed on the mixing main shaft 12, and can be driven by the mixing motor 11 to perform revolution movement with the mixing main shaft 12;

[0063] At least two planetary shafts 16 are inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com