Technology for casting motor shell

A technology of motor casing and casting process, which is applied in manufacturing tools, casting molding equipment, casting molds, etc., can solve the problems of waste of materials and molten iron smelting energy, difficulty in recycling waste sand, and high control requirements, and reduce technical requirements and labor force. Cost, saving electricity and raw material energy consumption, the effect of reducing technical requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] A casting process for a motor casing, comprising the following steps:

[0043] Install the sand core forming mold on the core shooter;

[0044] Add mold sand to the storage box of the core shooter;

[0045] Heat the sand core forming mold to a temperature of 190°C-230°C and control the pressure to 0.7kg / cm 2 -1.3kg / cm 2 ;

[0046] Inject the mold sand into the sand core forming mold to make the sand core;

[0047] Sinter the sand core for 80 seconds to 120 seconds;

[0048] Open the sand core forming mold and take out the sand core;

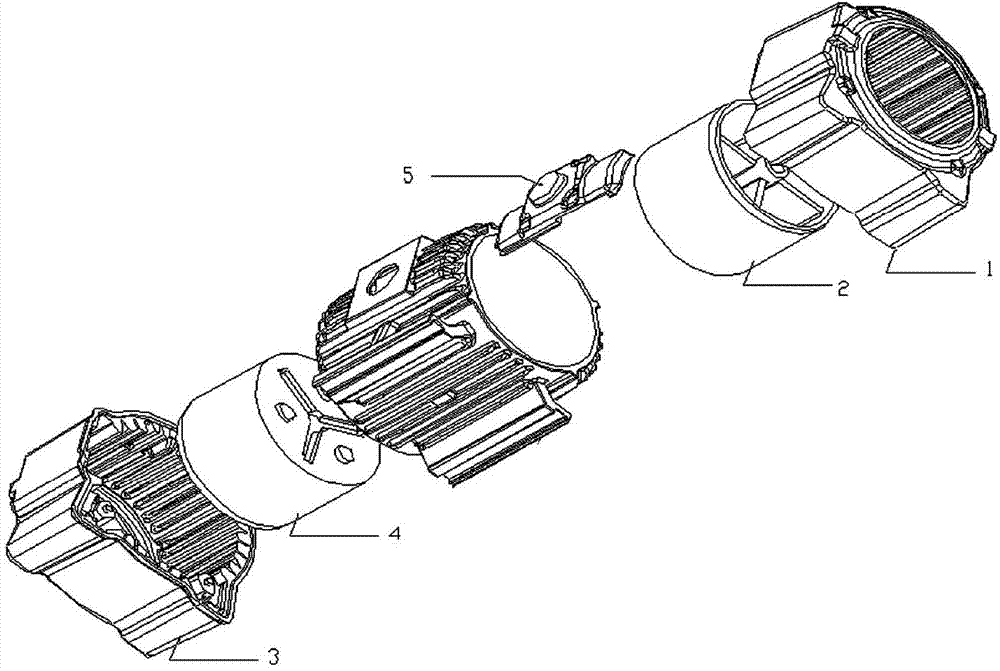

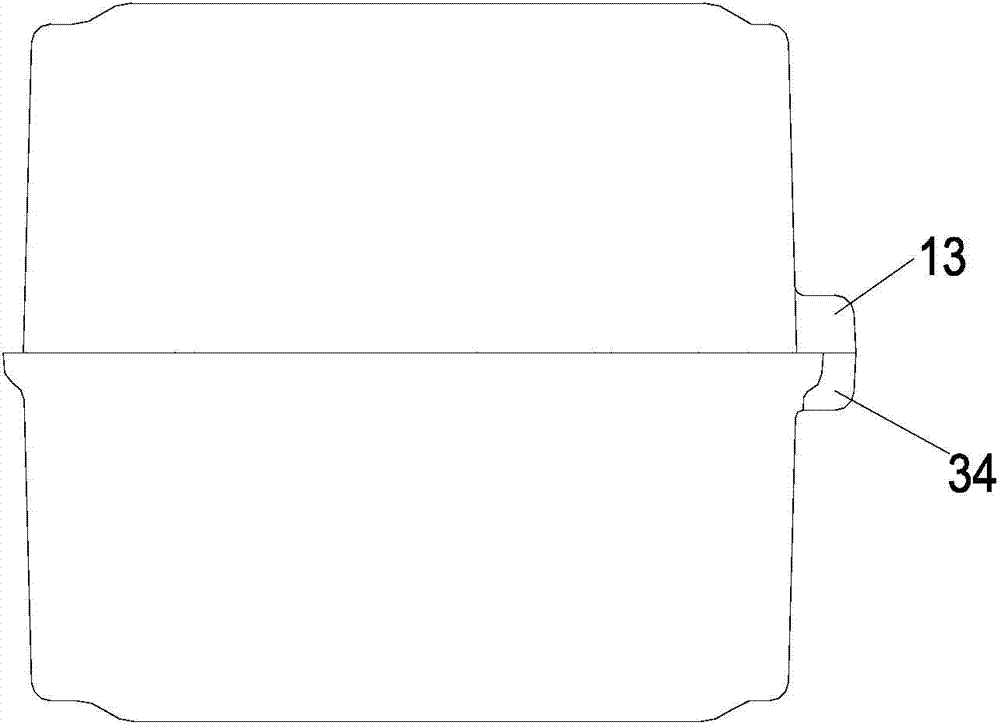

[0049] Check the integrity of the sand core, assemble the sand cores of each part of the shell into a whole sand core, and become a sand shell mold;

[0050] Put the sand shell mold into the pouring box and fix it, and pour the molten iron at a pouring temperature of 1200°C-1400°C;

[0051] After cooling and forming, open the pouring box and take out the casting.

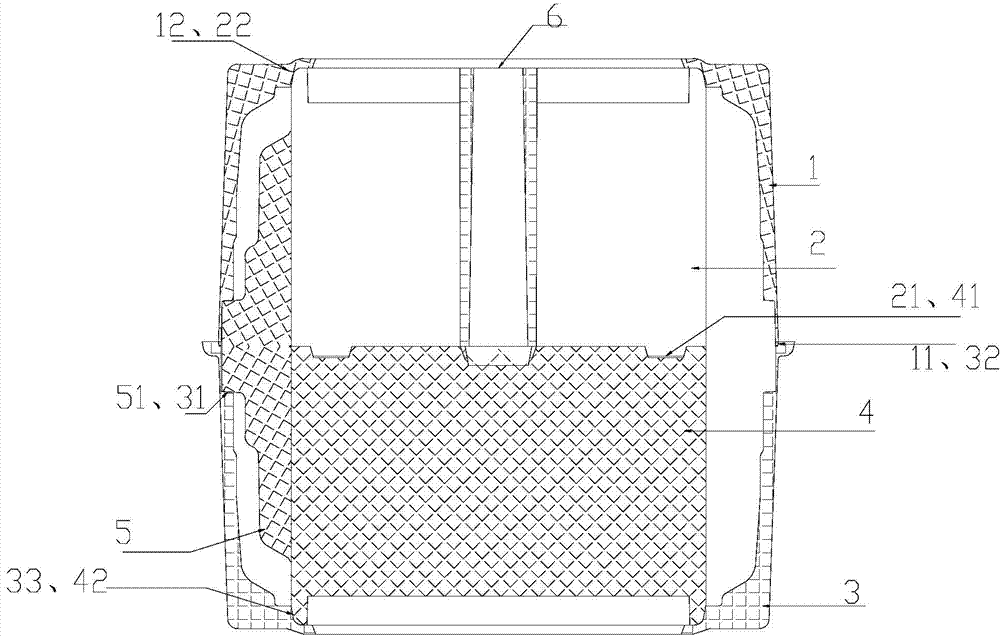

[0052] Preferably, the sand core of the motor housing includes an u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com