Machining Technology of Rear Axle Drive Bevel Gear

A technology of active bevel gear and processing technology, which is applied in the field of vehicles, can solve the problems of affecting the service life of the active bevel gear of the rear axle, low precision, coarse grain, etc., to reduce hardness, high precision, and improve the metallographic structure of the core Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

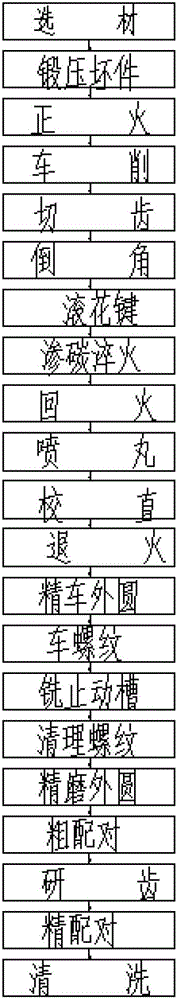

Image

Examples

Embodiment 1

[0034] Example 1: see figure 1 : a kind of rear axle active bevel gear processing technology shown, it comprises the following steps:

[0035] (1) Material selection, select low-carbon alloy steel bars that meet the size;

[0036] (2) Forging the blank, heating the material selected in step (1) to 850°C, and then putting it into the forging die for forging, so as to obtain the blank of the required size;

[0037] (3) Normalizing, put the blank into the heating furnace and heat it to Ac3+30°C, keep it warm for 30 minutes, take out the blank from the furnace and cool it in the air;

[0038] (4) Turning, the blank after normalizing is fixed on the lathe for turning processing, so that it conforms to the columnar structure of the size. Turning is divided into rough turning and finishing turning. Car processing.

[0039] (5) Gear cutting. Fix the blank obtained in step (4) to the gear cutting machine for gear cutting. The gear cutting is divided into rough cutting and fine cutti...

Embodiment 2

[0058] Example 2: see figure 1 : a kind of rear axle active bevel gear processing technology shown, it comprises the following steps:

[0059] (1) Material selection, select low-carbon alloy steel bars that meet the size;

[0060] (2) Forging the blank, heating the material selected in step (1) to 1000°C, and then putting it into the forging die for forging, so as to obtain the blank of the required size;

[0061] (3) For normalizing, put the blank into the heating furnace and heat it to Ac3+40°C. After holding the heat for 30 minutes, take the blank out of the furnace and cool it in the air;

[0062] (4) Turning, the blank after normalizing is fixed on the lathe for turning processing, so that it conforms to the columnar structure of the size. Turning is divided into rough turning and finishing turning. Car processing.

[0063] (5) Gear cutting. Fix the blank obtained in step (4) to the gear cutting machine for gear cutting. The gear cutting is divided into rough cutting a...

Embodiment 3

[0082] Example 3: see figure 1 : a kind of rear axle active bevel gear processing technology shown, it comprises the following steps:

[0083] (1) Material selection, select low-carbon alloy steel bars that meet the size;

[0084] (2) Forging the blank, heating the material selected in step (1) to 1200°C, and then putting it into the forging die for forging, so as to obtain the blank of the required size;

[0085] (3) Normalizing, put the blank into the heating furnace and heat it to Ac3+50°C, keep it warm for 30 minutes, take the blank out of the furnace and cool it in the air;

[0086] (4) Turning, the blank after normalizing is fixed on the lathe for turning processing, so that it conforms to the columnar structure of the size. Turning is divided into rough turning and finishing turning. Car processing.

[0087] (5) Gear cutting. Fix the blank obtained in step (4) to the gear cutting machine for gear cutting. The gear cutting is divided into rough cutting and fine cuttin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com