A gasket press-fit assembly machine

A technology for assembling machines and washers, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of wasting manpower and operation time, and difficult to guarantee product quality, and achieves time-saving, high-speed, high-performance solutions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The structure of the present invention will be further described below with reference to the accompanying drawings.

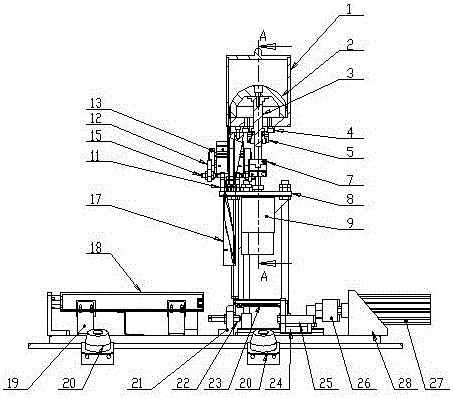

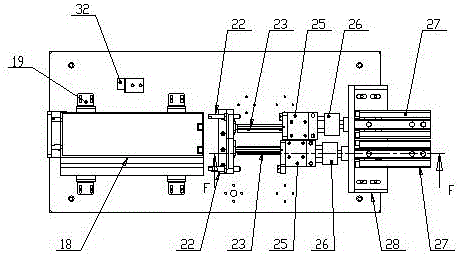

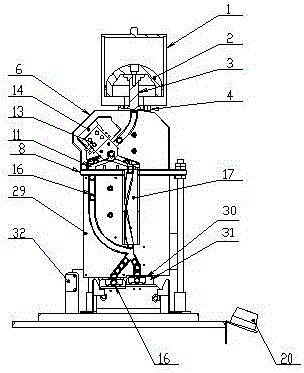

[0018] figure 1 , 2 , 3 shows a structural front view of a washer press-fit assembly machine. Among the figure, the gasket press-in assembly machine adopts pneumatic and motor control structure, and it includes an array mechanism, a sorting mechanism, a press-in mechanism and ink cartridge receiving platform 19.

[0019] The array mechanism fixes the motor 9 to the tray support plate 8, and drives the rotating disc 2 to rotate through the connection of the motor connecting shaft 10, the coupling 7, and the rotor shaft 3 to arrange the gasket 16 out of the hopper 1 into the tray 6.

[0020] The sorting mechanism fixes the jaw cylinder 13 to the jaw cylinder connecting plate 14, and the two ends of the jaw cylinder 13 respectively fix the sorting rod fixing plate 12, and the sorting rod 15 repeatedly stretches and moves through the jaw cylinder 13, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com