Laser annealing method and laser annealing device adopting laser auxiliary heating

A laser annealing and auxiliary heating technology, which is applied in laser welding equipment, metal processing equipment, electrical components, etc., can solve the problems of inability to use laser annealing, inconvenient and flexible, etc., and achieve the goal of optimizing the laser annealing process, simplifying the process, and high annealing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

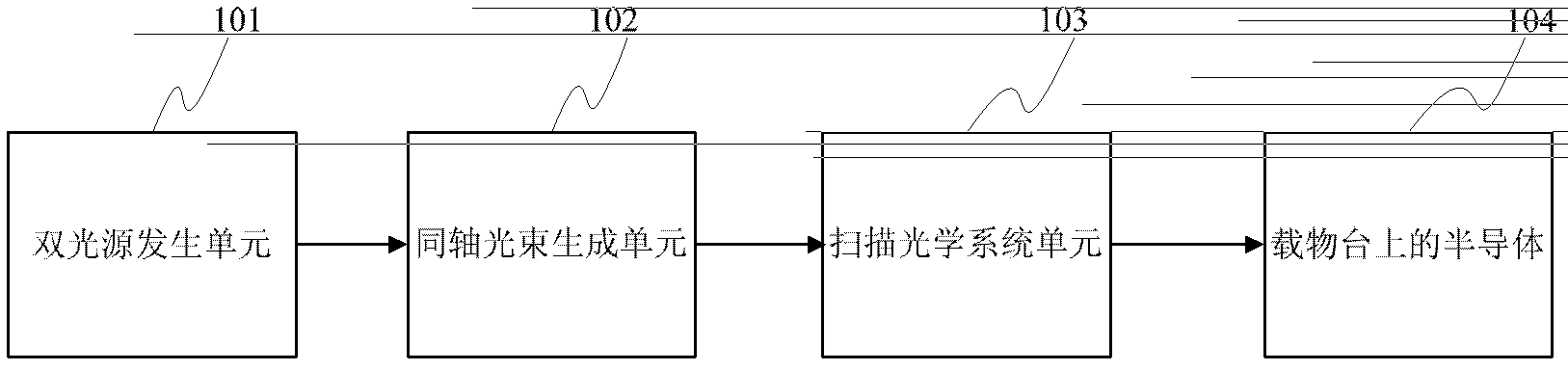

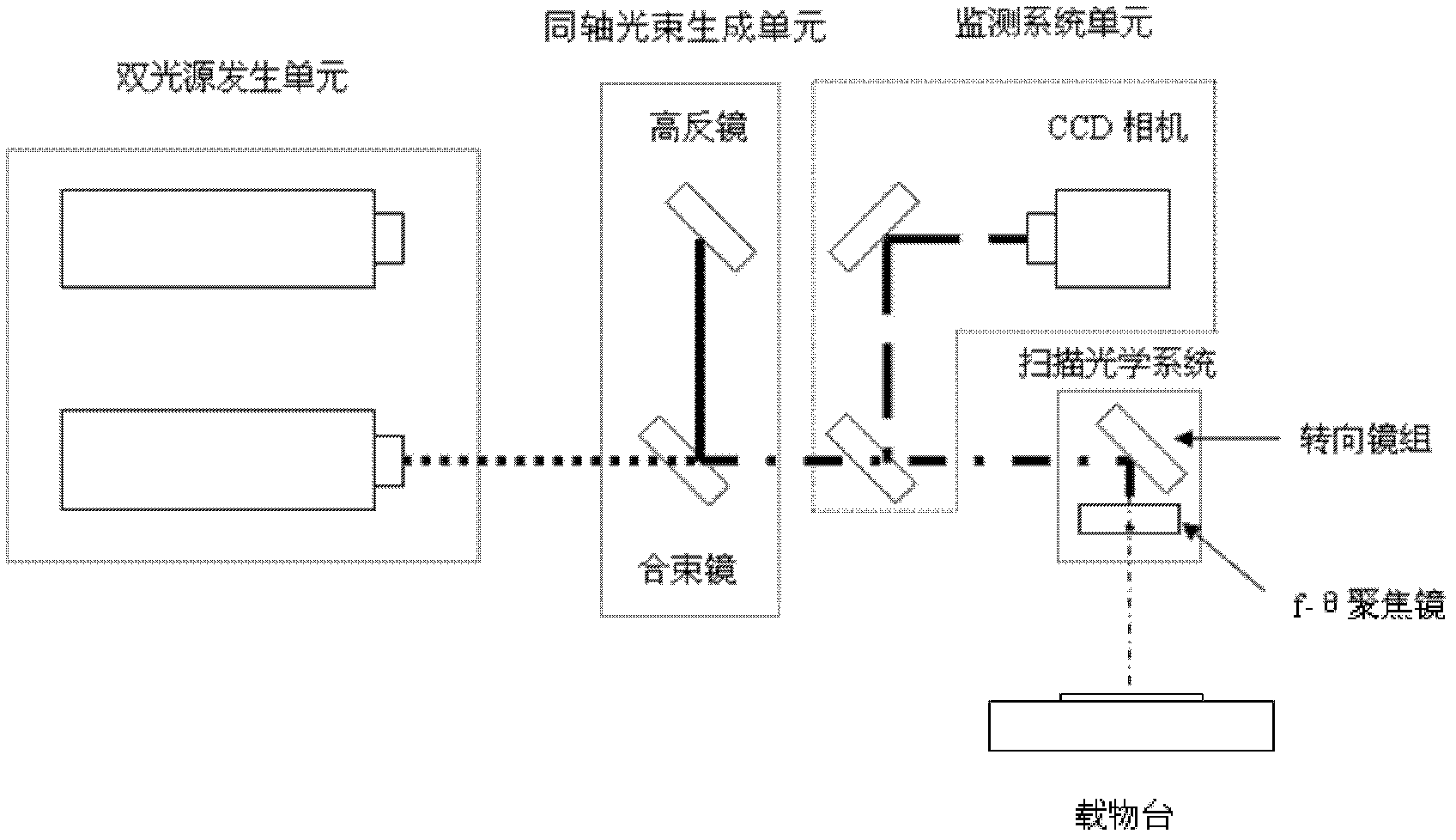

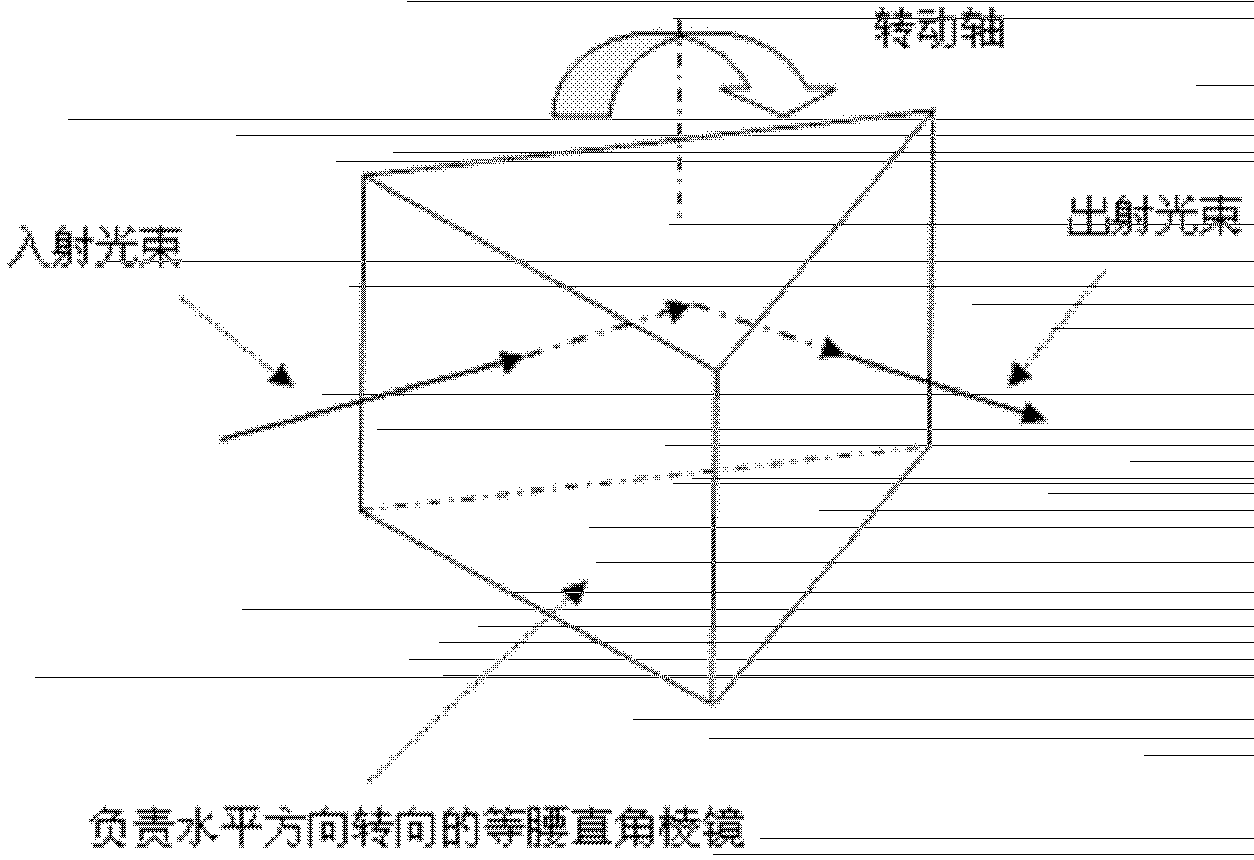

[0047] Such as Figure 1-b As shown, the present invention adopts a laser-assisted heating light source for coaxial transmission of the laser light source used for laser annealing, optimizes the activity of the surface of the semiconductor material to be annealed, and greatly improves the efficiency and effect of laser annealing. The method of the invention creates an original laser annealing scanning method in which the annealing light source performs laser annealing scanning in the horizontal and vertical directions on the surface of the semiconductor material, and changes the traditional laser annealing method in which the laser annealing light source is irradiated at a fixed point and the semiconductor material is rotated on the loading platform. The improved laser annealing method can realize laser annealing in a designated area on the semiconductor surface, which is a feature that traditional laser annealing equipment does not have. The technical solution adopted in the ...

Embodiment 2

[0060] Such as Figure 5 As shown, this figure is one of the optional strategies for the co-optical axis transmission strategy described in the above method, specifically including:

[0061] Step 501, the laser beam used for auxiliary heating is turned and irradiated to the rear surface of the beam combining mirror through a high reflection mirror, and the rear surface of the beam combining mirror is coated with a high reflectivity film for the wavelength of the auxiliary heating laser, so that the auxiliary heating laser beam is once again Turn to transmission.

[0062] Step 502, the laser beam used for laser annealing is incident on the front surface of the beam combiner, and the front surface of the beam combiner is coated with a high transmittance film for the wavelength of the laser annealing laser, and the laser beam used for laser annealing passes through the beam combiner. The beam mirror continues to travel forward.

[0063] Step 503, adjusting the relative position...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com