Ratio automatic management and control system

A control system and automatic proportioning technology, applied in various fluid ratio control and other directions, can solve the problems of high calculation error rate, slow completion speed, and complicated maneuverability, and achieve the effect of simple control, fast completion speed, and time saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

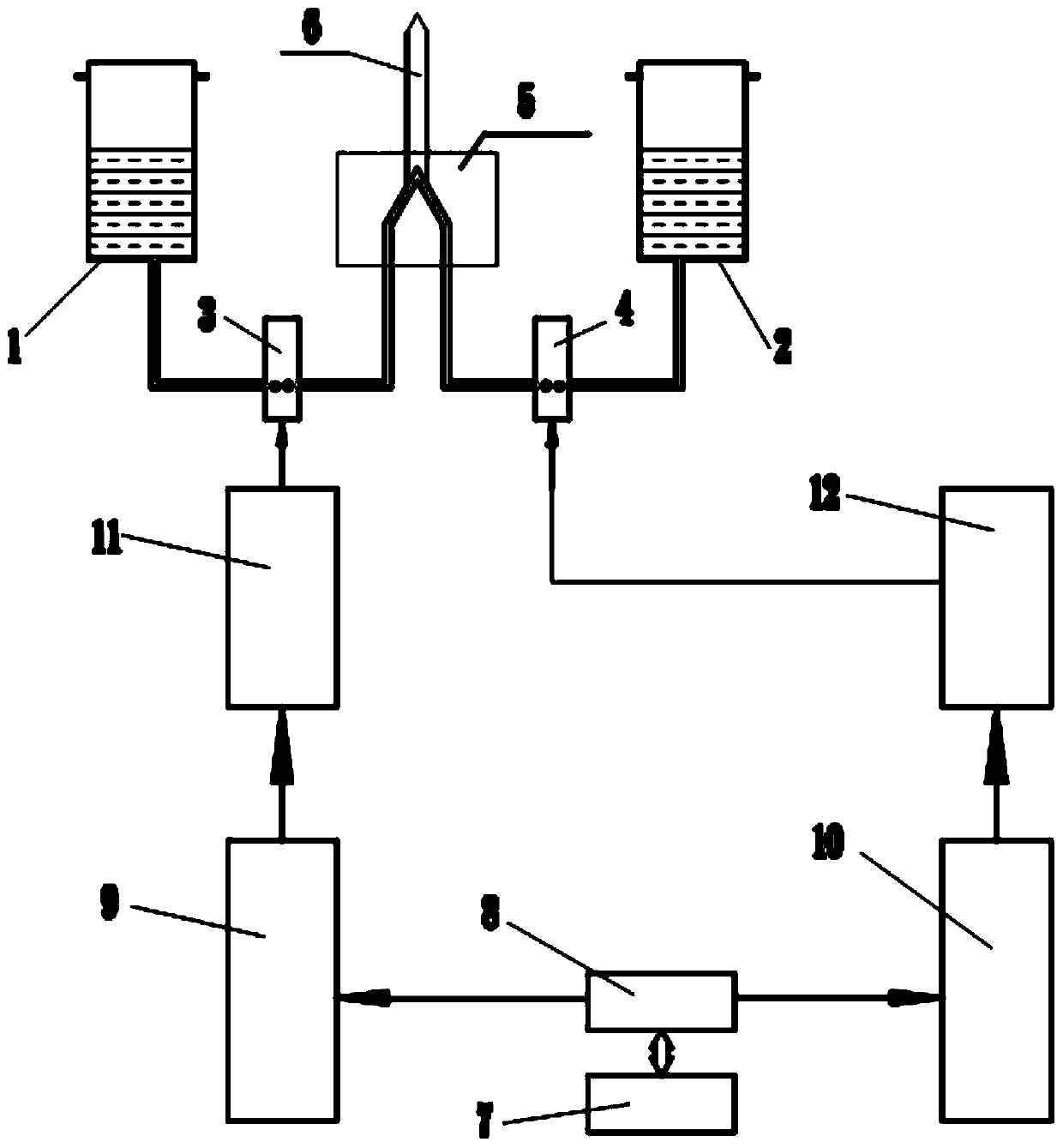

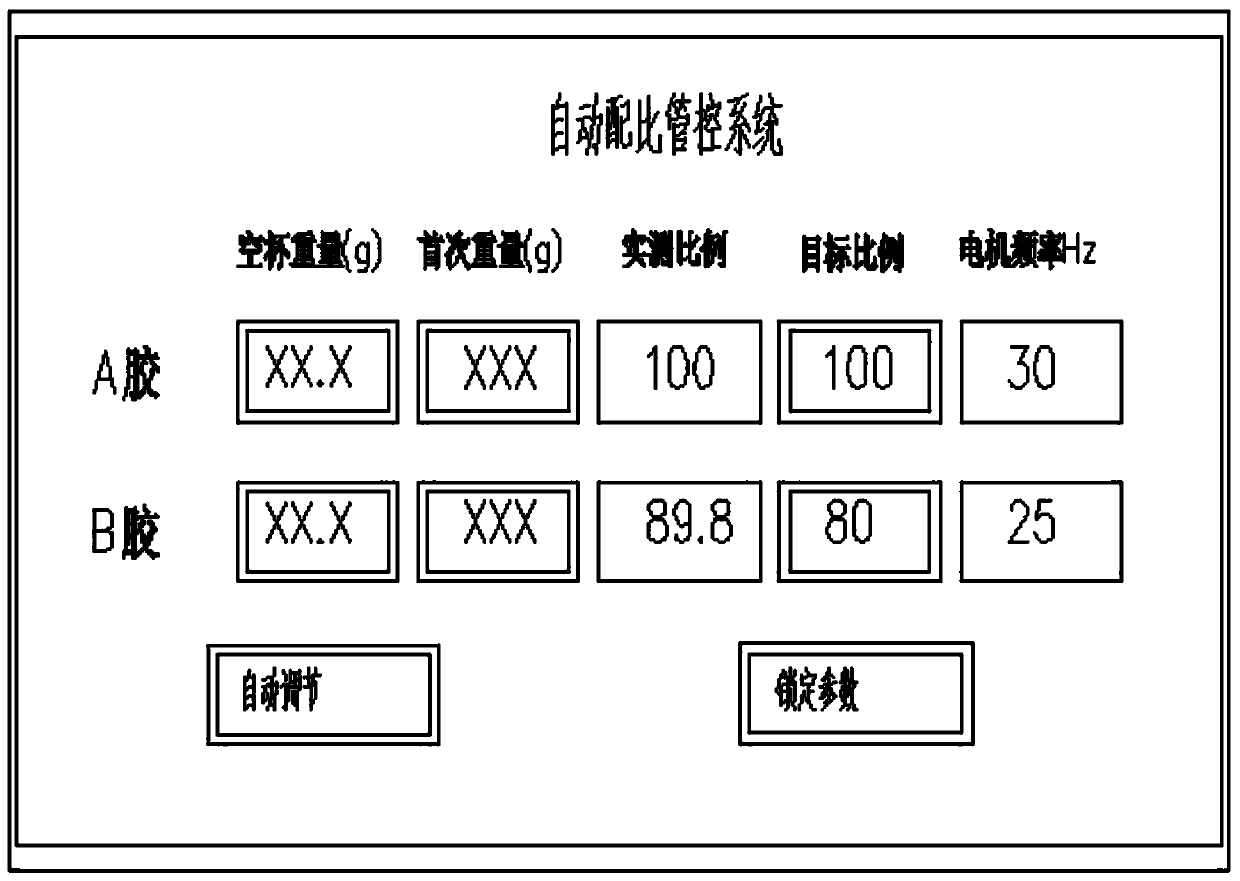

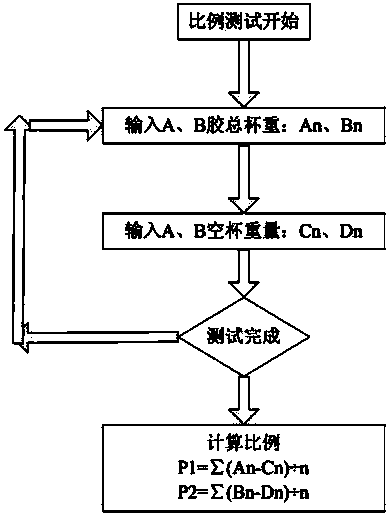

[0019] like figure 1 , 2 , 3 and 4 describe its embodiment: an automatic proportioning control system, A glue is housed in the glue container 1, B glue is housed in the glue container 2, and the glue container 1 passes through the pipeline and the metering pump 3 outside the barrel Connection, the glue container 2 is connected with the metering pump 4 outside the barrel through the pipeline, the A glue and the B glue are respectively pumped by the metering pump 3 and the metering pump 4 to the rubber mixing valve 5 and start to converge, and then in the static mixer 6 Carry out sufficient mixing, which constitutes the delivery and mixing circuit of A / B glue. This system is also provided with man-machine interface 7, this man-machine interface 7 is connected with PLC controller 8 by signal; This PLC controller 8 is connected with frequency converter 9 by signal, and this frequency converter 9 is connected with motor 11 by signal, and this motor 11 It is mechanically connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com