A self-locking clamping device based on thermally induced linear expansion

A self-locking clip and linear expansion technology, applied in the field of mechanical clamping, can solve problems such as noise pollution, environmental pollution, energy consumption, etc., and achieve the effects of reducing energy conversion links, reducing use costs, and improving utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

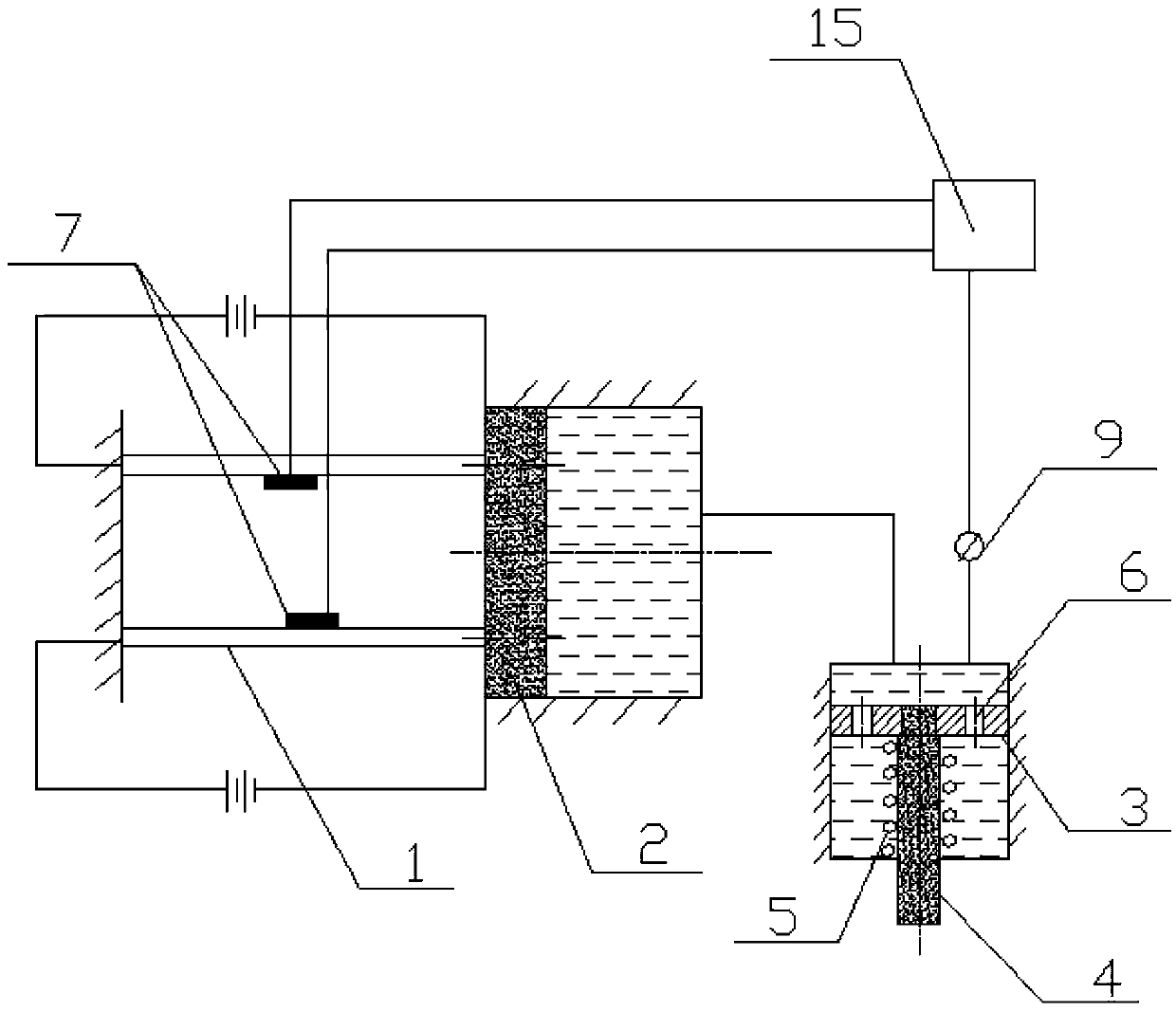

[0044] like figure 1 As shown, the heat-sensitive drive components are two heat-sensitive transmission rods 1 symmetrically arranged, one end of the heat-sensitive transmission rod 1 is fixed, the other end is connected to the driving piston 2, and the temperature control component is electrically connected to the heat-sensitive transmission rod. By energizing the circuit, the heat-sensitive transmission rod heats up under the action of electric heating or naturally heats up after cooling. During the heating process, the heat-sensitive transmission rod gradually elongates, and gradually pushes the driving piston forward under the action of the heat-sensitive transmission rod. Move, and then push the piston rod down to press the workpiece; when it is released, stop heating or cooling, so that the heat-sensitive transmission rod shrinks and resets, and the output piston and piston rod reset under the action of the return spring 5.

[0045] Wherein, the number of the heat-sensiti...

Embodiment 2

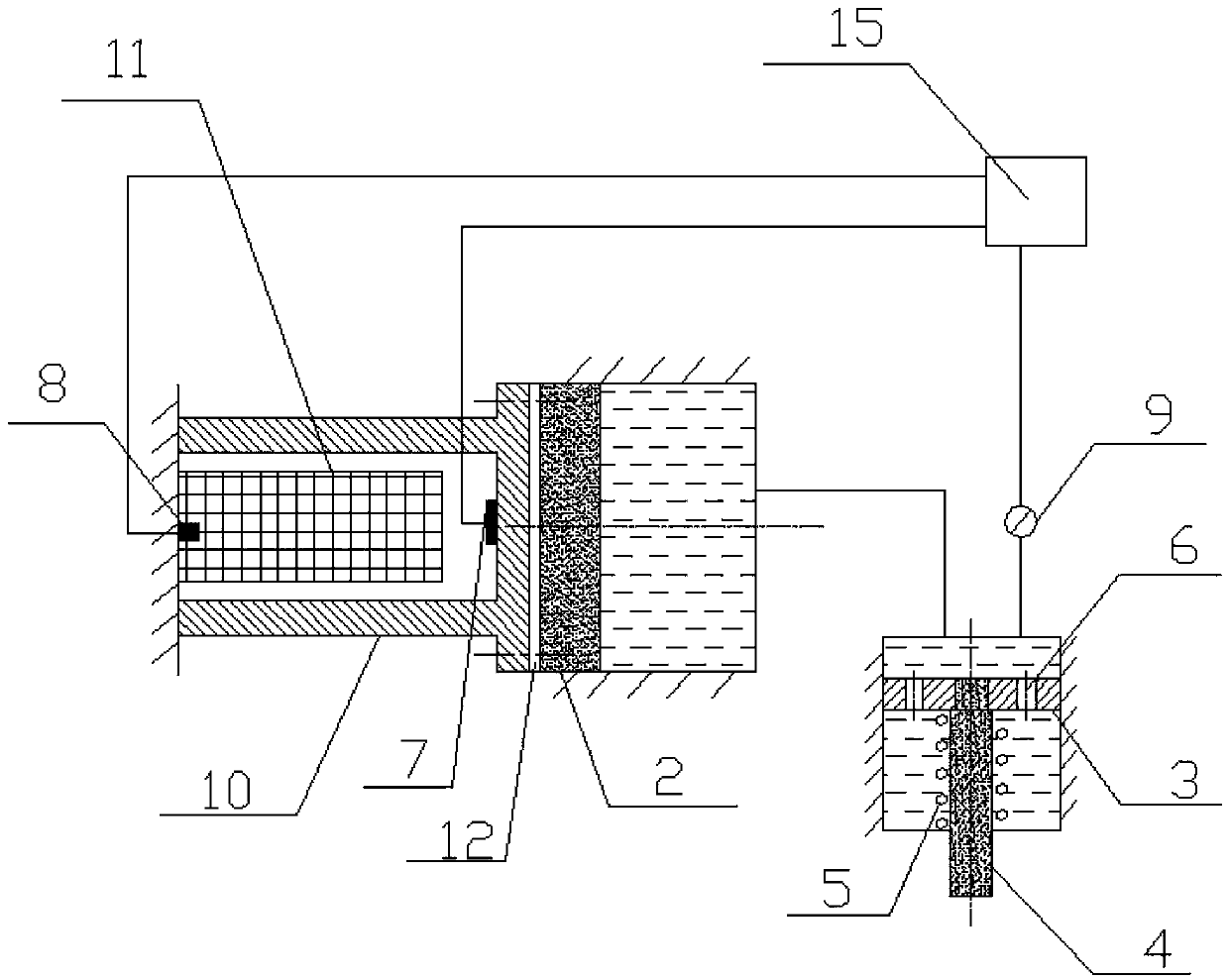

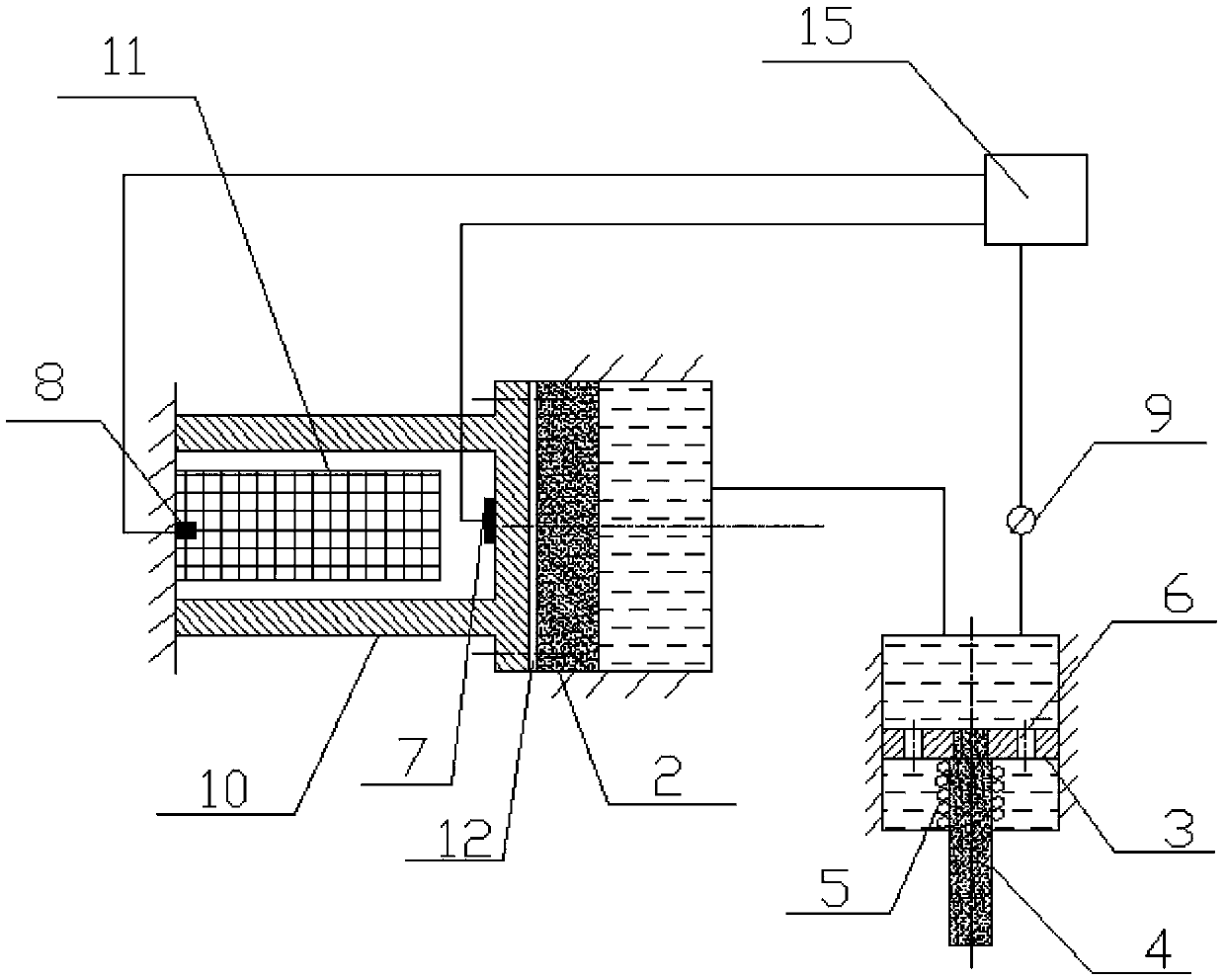

[0049] like figure 2 , 3 As shown, the heat-sensitive driving component is a hollow thin-walled tube 10 , and a semiconductor heating / refrigerating element 11 is arranged inside the hollow thin-walled tube. One end of the hollow thin-walled tube 10 is fixed, and the other end is connected to the driving piston 2 .

[0050] A heat insulating pad 12 is provided at the joint between the hollow thin-walled tube and the driving piston to prevent the hollow thin-walled tube from overheating and damaging the driving piston.

[0051] By using the semiconductor heating / cooling fast conversion technology to act on the hollow thin-walled tube, due to the heat-induced linear expansion of the material, the size of the material will increase approximately linearly with the increase of temperature, and vice versa. That is, in the semiconductor cooling state, the material shrinks, and in the heating state, the material elongates. Therefore, controllable two-way micro-displacement can be ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com