High-energy X-ray radiographic film changing robot

An X-ray and robotic technology, applied in the field of high-energy X-ray non-destructive testing, can solve the problems of long safety waiting time and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

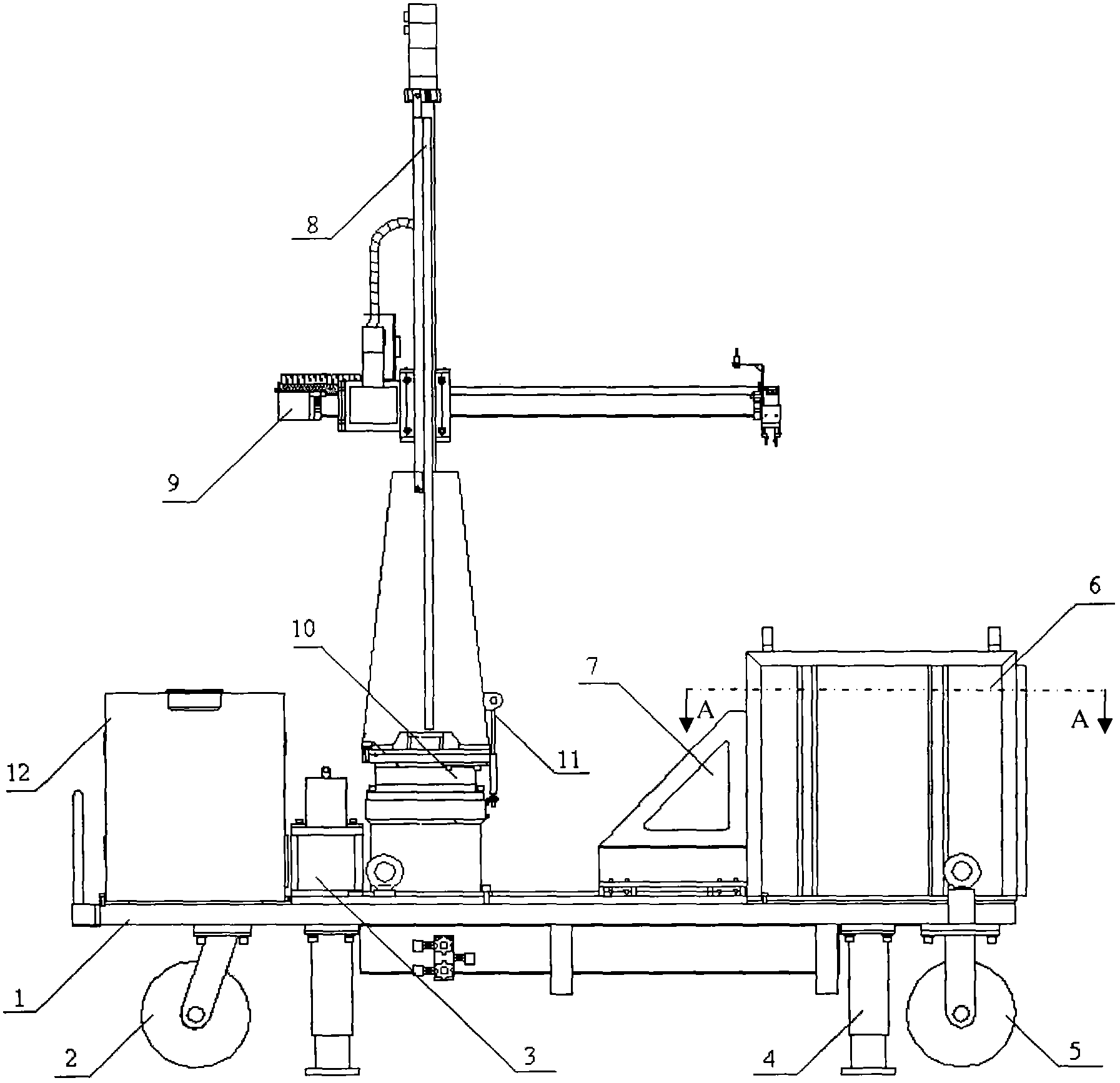

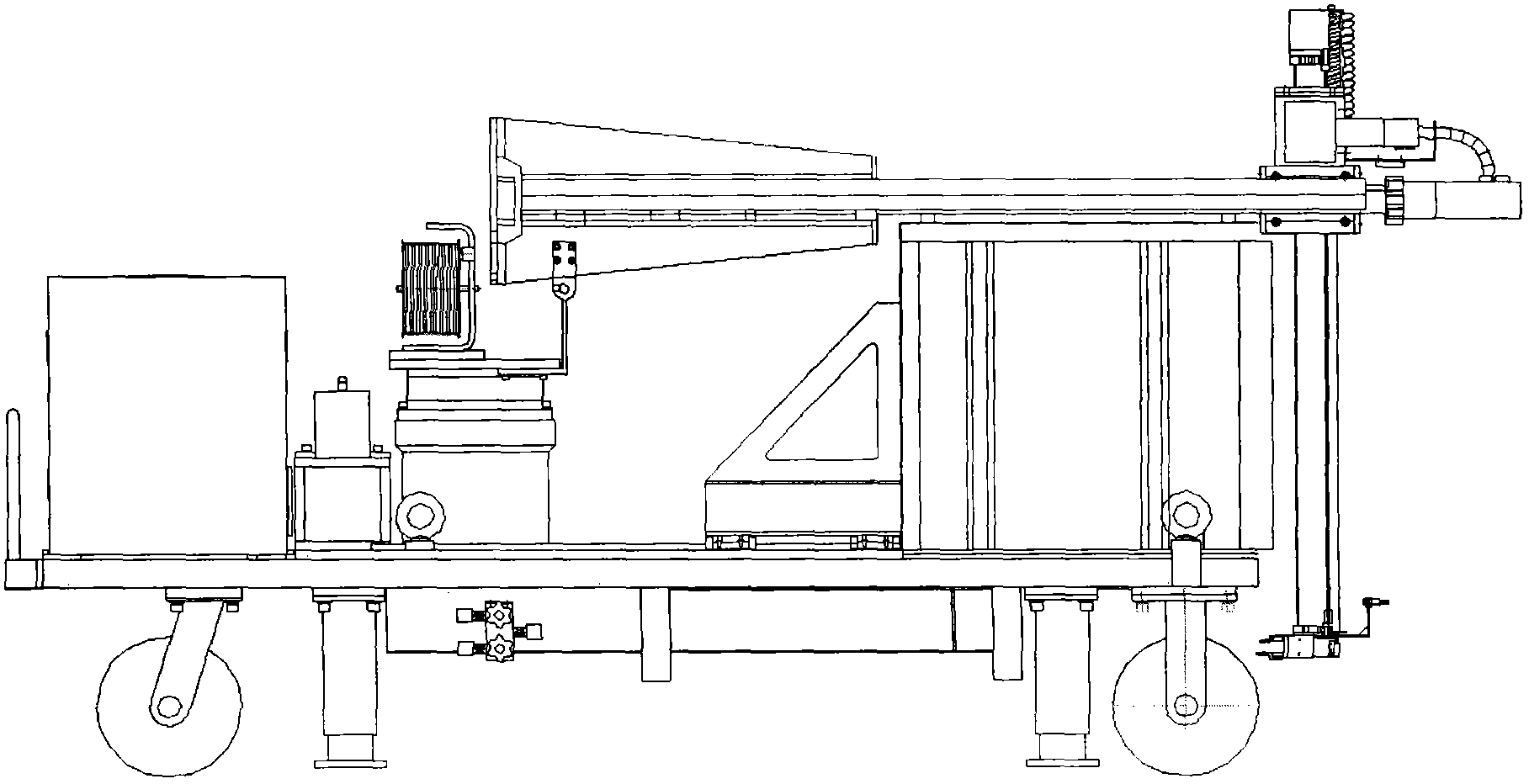

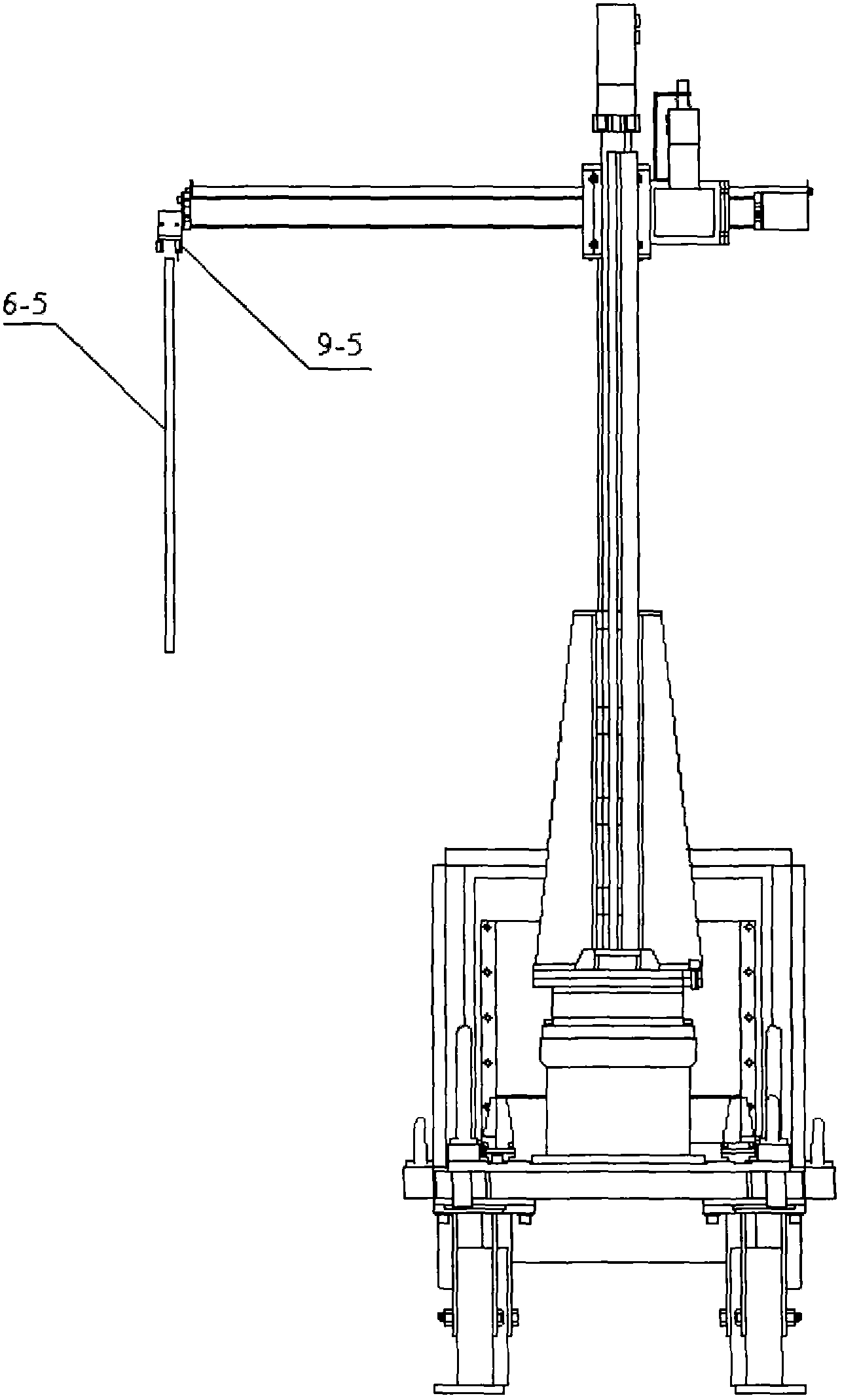

[0044] In order to describe the design idea and method of the present invention in detail, the following will be described in detail in conjunction with the accompanying drawings.

[0045] 1. Principle of system structure

[0046] 1. Movable car body

[0047] like figure 1As shown, two sets of roller groups are installed at the bottom of the movable car body 1, one is the front roller group 5 in the direction of the film library, and this group of rollers is fixed in one direction and cannot change direction; The group rollers are universal wheels, which can turn 360 degrees, and the front roller group 5 and the rear roller group 2 respectively have two before and after. The main body of the roller is steel, and the outer surface is made of plastic material. This structure can adapt to the movement of the movable car body 1 within a small range. A cover of manual hydraulic jack 4 is equipped with at the bottom of the movable car body 1, and each two supporting legs front an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com