Tire pressure monitoring system

A tire pressure monitoring and pressure sensor technology, which is applied in tire measurement, tire parts, transportation and packaging, etc., can solve problems such as low measurement accuracy, system failure, and high power consumption, and achieve high measurement accuracy and performance. The effect of low power consumption and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

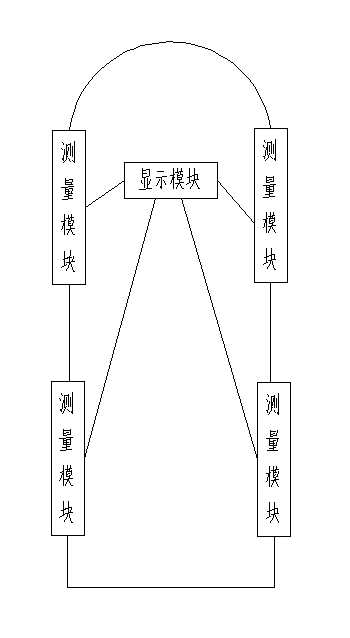

[0017] Such as figure 1 As shown, the tire pressure monitoring system of the present invention adopts a direct measurement method, including a measurement module and a display module. There are four measurement modules, and the four measurement modules are respectively installed on the air valves of the four tires of the automobile; The display module is installed in the cab of the car; the four measurement modules communicate with the display module in a radio frequency manner.

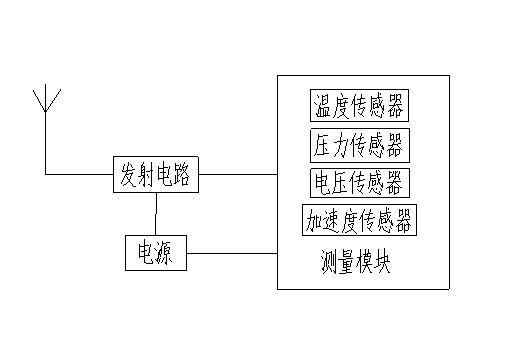

[0018] Such as figure 2 as shown, figure 2 It is a composition diagram of a measurement module, and the measurement module includes a pressure sensor, a temperature sensor, an acceleration sensor, a single-chip microcomputer, a transmitting circuit and a power supply. Described pressure sensor, temperature sensor, acceleration sensor and single-chip microcomputer are all in NPX-C01780, and described pressure sensor, temperature sensor, acceleration sensor are respectively used for measuring the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com