Modified slag compound admixture and preparation method thereof

A composite admixture and slag technology, which is applied in the field of modified slag composite admixture and its preparation, can solve the problem of not implementing high value-added resource utilization, etc., so as to increase added value, reduce hydration heat, and improve impermeability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

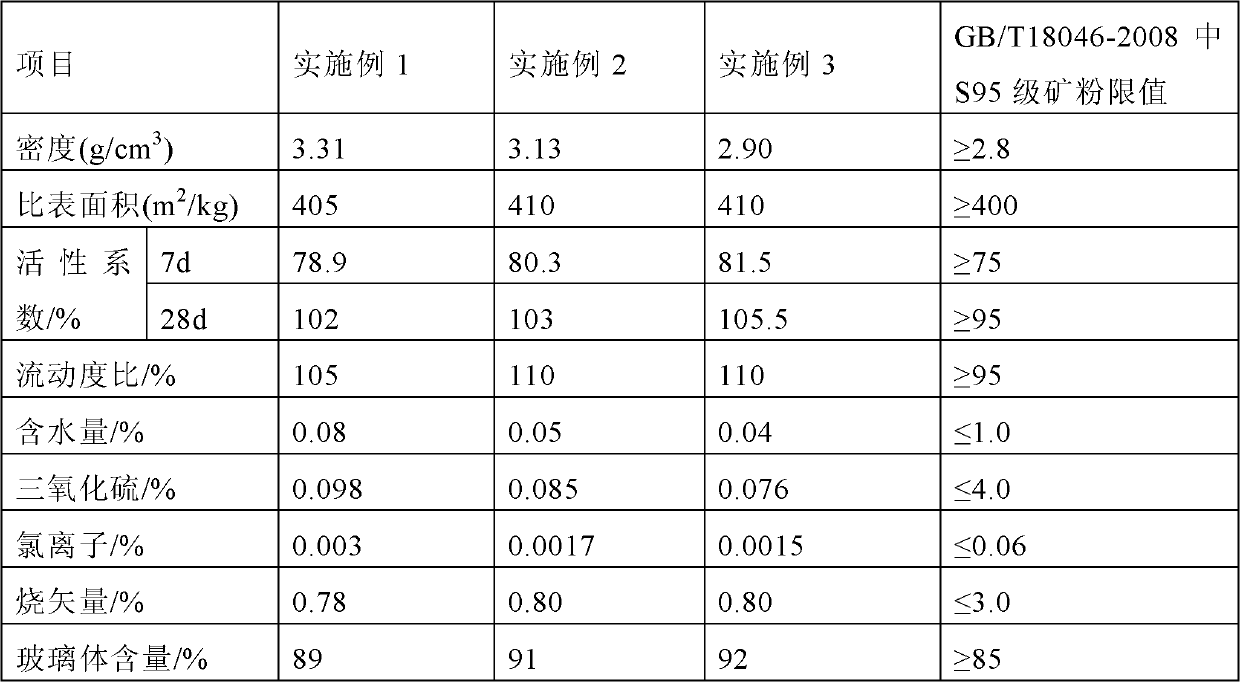

Embodiment 1

[0026] The mass percentage of S95 grade slag powder is 60%, and the density is 2.90g / cm 3 , specific surface area 415m 2 / kg; 7-day activity index ≥ 75%, 28-day activity index ≥ 95%, sulfur trioxide content ≤ 4.0%, chloride ion content ≤ 0.06%.

[0027] The mass percentage of ground converter steel slag powder is 30%, and the density is 3.90g / cm 3 , specific surface area 405m 2 / kg, 28-day activity index ≥ 75%, sulfur trioxide content ≤ 4.0%, chloride ion content ≤ 0.05%, alkalinity ≥ 2.2.

[0028] The mass percentage of white slag is 10%, and the specific surface area is 420m 2 / kg.

[0029] Add 60% slag powder by mass, 30% steel slag powder and 10% white slag into the mixer and stir for 5 minutes to prepare the modified slag composite admixture . Refer to GB / T 18046-2008 "Granulated Blast Furnace Slag Powder Used in Cement and Concrete" to test the performance of the modified slag composite admixture sample in all aspects. The benchmark cement is Conch brand 42.5 Port...

Embodiment 2

[0031]The mass percentage of S95 grade slag powder is 68%, and the density is 2.90g / cm 3 , specific surface area 415m 2 / kg, 7-day activity index ≥ 75%, 28-day activity index ≥ 95%, sulfur trioxide content ≤ 4.0%, chloride ion content ≤ 0.06%.

[0032] The mass percentage of ground converter steel slag powder is 25%, and the density is 3.90g / cm 3 , specific surface area 405m 2 / kg, 28-day activity index ≥ 75%, sulfur trioxide content ≤ 4.0%, chloride ion content ≤ 0.05%, alkalinity ≥ 2.2.

[0033] The mass percentage of white slag is 7%, and the specific surface area is 420m 2 / kg.

[0034] Add 68% slag powder by mass, 25% steel slag powder and 7% white slag into the mixer, and stir for 4 minutes to prepare the modified slag composite admixture . Refer to GB / T 18046-2008 "Granulated Blast Furnace Slag Powder Used in Cement and Concrete" to test the performance of the modified slag composite admixture sample in all aspects. The benchmark cement is Conch brand 42.5 Portla...

Embodiment 3

[0036] The mass percentage of S95 grade slag powder is 80%, and the density is 2.90g / cm 3 , specific surface area 415m 2 / kg, 7-day activity index ≥ 75%, 28-day activity index ≥ 95%, sulfur trioxide content ≤ 4.0%, chloride ion content ≤ 0.06%.

[0037] The mass percentage of ground electric furnace steel slag powder is 15%, and the density is 3.90g / cm 3 , specific surface area 405m 2 / kg; 28-day activity index ≥ 75%, sulfur trioxide content ≤ 4.0%, chloride ion content ≤ 0.05%, alkalinity ≥ 2.2.

[0038] The mass percentage of white slag is 5%, and the specific surface area is 420m 2 / kg.

[0039] Add 80% slag powder by mass, 15% steel slag powder and 5% white slag into the mixer, and stir for 3 minutes to prepare the modified slag composite admixture . Refer to GB / T18046-2008 "Granulated Blast Furnace Slag Powder Used in Cement and Concrete" to test the performance of the modified slag composite admixture sample in all aspects. The benchmark cement is Conch brand 42.5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com