Method for activating and modifying steel slag by residual heat of converter steel slag

A technology of converter steel slag and steel slag, which is applied in the field of utilization of converter steel slag, can solve the problems of little significance for large-scale application of steel slag, little space for performance improvement, and congenital deficiency of steel slag, so as to ensure gelling performance and avoid direct losses , to achieve the effect of reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

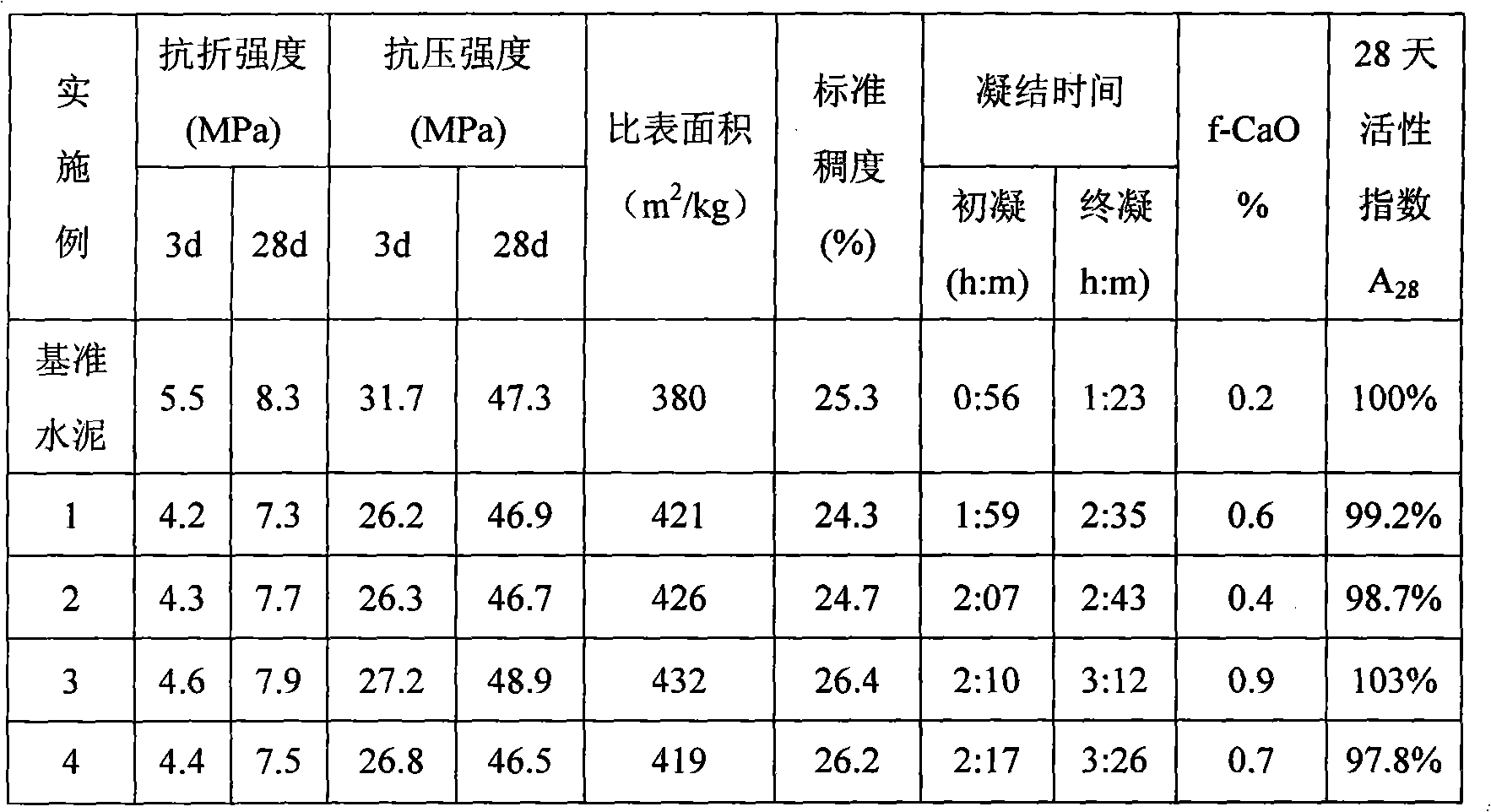

Embodiment 1

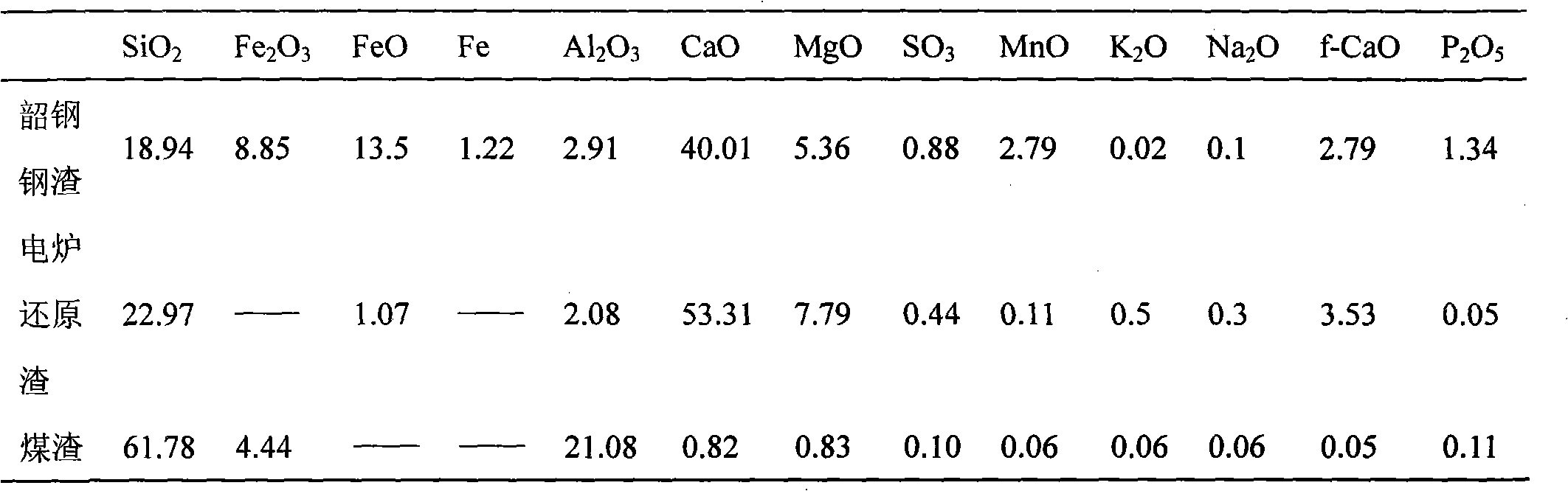

[0029] The slag discharge capacity of the converter steel slag is 3 tons, and the performance adjustment material is 10% of the steel slag weight.

[0030] Mix electric furnace reduction slag, coal slag, and additives according to the following parts by weight to prepare performance-adjusting materials:

[0031] Electric furnace reduced slag 70 parts (210 kg)

[0032] Cinder 25 parts (75 kg)

[0033] 5 parts plastic-retaining starch (15 kg)

[0034] After the performance adjustment material is granulated, it is placed in a steel slag ladle.

[0035] The property-adjusting material and steel slag are mixed by the impact force of molten steel slag pouring.

[0036] The mixed performance adjusting material and steel slag were heated in a slag ladle for 8 hours.

[0037] Under the action of waste heat of molten steel slag, chemical reaction occurs between steel slag and performance adjusting material.

Embodiment 2

[0039] The amount of slag discharged from the converter steel slag is 3 tons, and the performance adjustment material is 15% of the weight of the steel slag.

[0040] Mix electric furnace reduction slag, coal slag, and additives according to the following parts by weight to prepare performance-adjusting materials:

[0041] Electric furnace reduced slag 80 parts (360 kg)

[0042] 17 cinders (76.5 kg)

[0043] 3 parts thickening starch (13.5 kg)

[0044] After the performance adjustment material is granulated, it is placed in a steel slag ladle.

[0045] The property-adjusting material and steel slag are mixed by the impact force of molten steel slag pouring.

[0046] The mixed performance adjusting material and steel slag were hot stuffed in a slag ladle for 12 hours.

[0047] Under the action of waste heat of molten steel slag, chemical reaction occurs between steel slag and performance adjusting material.

Embodiment 3

[0049] The amount of slag discharged from the converter steel slag is 3 tons, and the performance adjustment material is 20% of the weight of the steel slag.

[0050] Mix electric furnace reduction slag, coal slag, and additives according to the following parts by weight to prepare performance-adjusting materials:

[0051] Electric furnace reduced slag 90 parts (540 kg)

[0052] Cinder 7 parts (42 kg)

[0053] 3 parts (18 kg) plastic-proof thickening starch

[0054] After the performance adjustment material is granulated, it is transported to the steel slag ladle by a screw conveyor.

[0055] The property-adjusting material and steel slag are mixed by the impact force of molten steel slag pouring.

[0056] The mixed performance adjusting material and steel slag were hot stuffed in a slag ladle for 18 hours.

[0057] Under the waste heat of the molten steel slag, the chemical reaction occurs between the steel slag and the performance adjusting material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| activation index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com