Method for preparing fracturing propping agent specially used for shale gas from poor bauxite

The technology of fracturing proppant and bauxite is applied in the field of preparing proppant and preparing special fracturing proppant for shale gas by using poor bauxite, which can solve the problem of unstable proppant performance, high sintering temperature and production cost. High problems, to achieve the effect of being conducive to environmental protection, reducing the crushing rate, easy to operate and easy to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

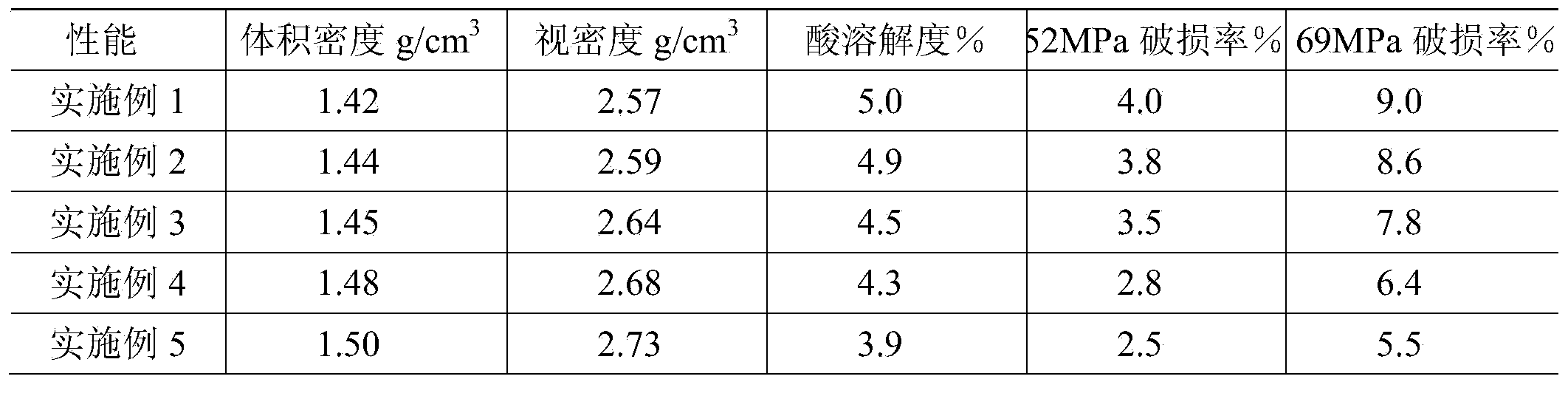

Examples

Embodiment 1

[0027] 1) Put industrial coke into a ball mill and use alumina balls as balls to add water to wet mill for 1 hour to form powdered carbon slurry, which passes through a 180-mesh sieve; among them, when industrial coke is wet-milled, alumina balls and industrial coke are controlled The mass ratio with water is 2:1:0.6;

[0028] 2) According to the mass percentage, 60% active Al 2 o 3 Powder and 40% silicon micropowder are evenly mixed to obtain a highly active composite sintering aid; among them, the active Al 2 o 3 Powder and silica powder particle size are less than 5μm;

[0029] 3) According to the mass percentage, mix 94% of low-grade bauxite and 6% of composite sintering aid to obtain a mixture, put the mixture into a ball mill, use alumina balls as balls and add water to wet mill for 3 hours, Form a mixed slurry, and the mixed slurry is passed through a 320-mesh sieve; wherein, when the mixed material is wet-ground, the mass ratio of the alumina ball stone, the mixed ...

Embodiment 2

[0034] 1) Put industrial coke into a ball mill and use alumina balls as balls to add water to wet mill for 0.9h to form powdered carbon slurry, which passes through a 180-mesh sieve; among them, during wet grinding of industrial coke, control alumina balls, industrial The mass ratio of coke and water is 2.2:1:0.7;

[0035] 2) According to the mass percentage, 65% active Al 2 o 3 Powder and 35% silicon powder are evenly mixed to obtain a highly active composite sintering aid; among them, the active Al 2 o 3 Powder and silica powder particle size are less than 5μm;

[0036] 3) According to the mass percentage, mix 95% of low-grade bauxite and 5% of composite sintering aid to obtain a mixture, put the mixture into a ball mill, use alumina balls as balls and add water to wet mill for 2.5 hours , form mixed mud, mixed mud crosses 320 mesh sieves; Wherein, when mixed material wet grinding, the mass ratio of controlling alumina ball stone, mixed material and water is 2.2:1:0.6; ...

Embodiment 3

[0041] 1) Put the industrial coke into the ball mill, use alumina balls as the balls and add water for wet grinding for 0.8h, and the grinding time is 20 to form powdered carbon slurry, which passes through a 180-mesh sieve; among them, during wet grinding of industrial coke, control alumina The mass ratio of ball stone, industrial coke and water is 2.3:1:0.7;

[0042] 2) According to the mass percentage, 70% active Al 2 o 3 Powder and 30% silicon micropowder are evenly mixed to obtain a highly active composite sintering aid; among them, the active Al 2 o 3 Powder and silica powder particle size are less than 5μm;

[0043] 3) According to the mass percentage, mix 96% of aluminum ore waste and 4% of composite sintering additives to obtain a mixture, put the mixture into a ball mill, use alumina balls as balls and add water to wet mill for 2 hours to form Mix the mud, and pass the mixed mud through a 320-mesh sieve; wherein, when the mixed material is wet-ground, the mass ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com