An automatic load sharing device for a power split gear system

A technology of split gear and automatic load equalization, applied in the direction of gear transmission device, transmission device, hoisting device, etc., can solve the problems of uncompact space structure and increased total weight of load equalizing device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

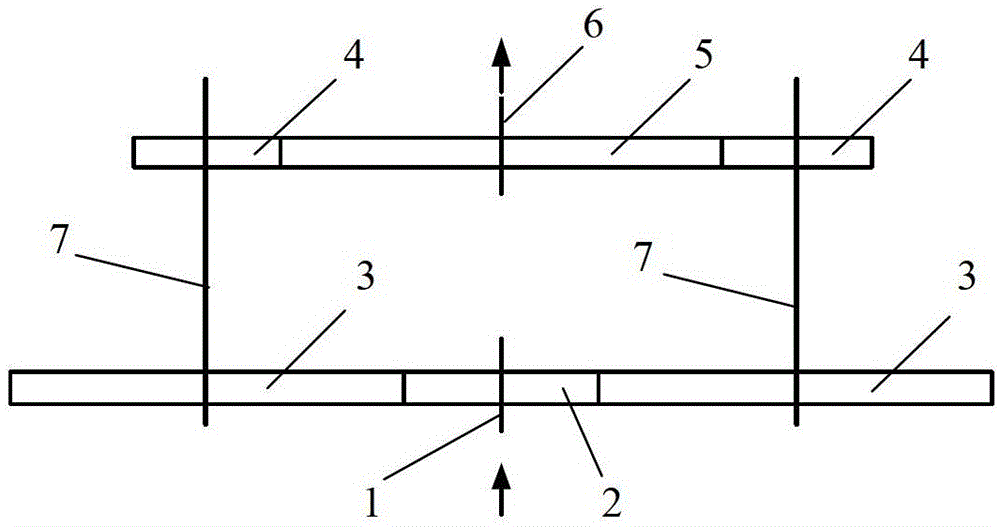

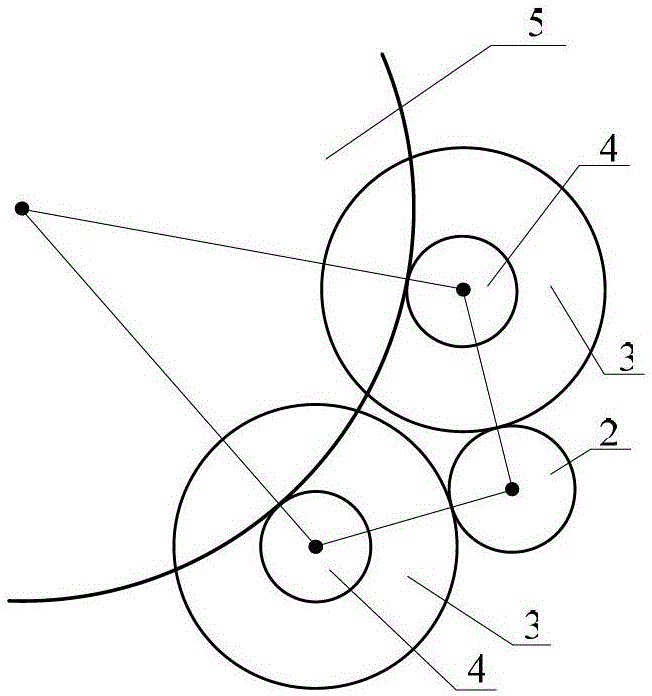

[0024] refer to Figure 1-Figure 4 The automatic load equalizing device of the power splitting gear system of the present invention includes an input device, an output device and two double gear shafts 7; the input device includes a split torque input shaft 1, an input stage pinion 2 and two input stage large gears 3, The output device comprises a power output shaft 6 , two output stage pinions 4 and an output stage bull gear 5 .

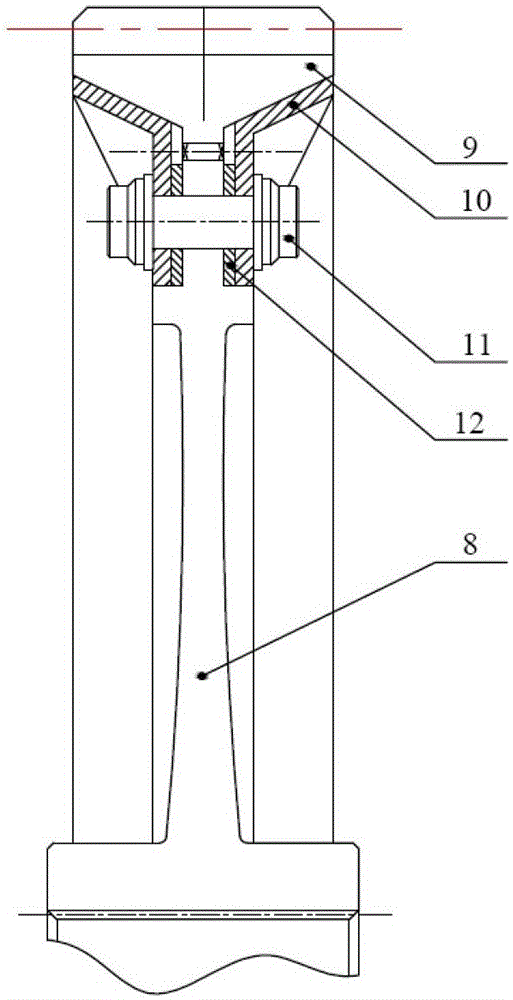

[0025] The two duplex gear shafts are divided into left and right branches, each of which has a duplex gear shaft 7 connected to an input-stage large gear 3 and an output-stage pinion 4 . The input stage pinion gear 2 is processed into one body with the power input shaft 1, and meshes with the two input stage large gears 3 respectively; the two output stage pinion gears 4 are fixedly connected with the double gear shaft 7, and are respectively connected with the output stage large gears 5 meshed. Both the input stage pinion gear 2 and the two inpu...

Embodiment 2

[0032] Such as Figure 5 As shown, another embodiment of the automatic load equalizing device of the power split gear system of the present invention also includes a reversing device, which includes a power input shaft 13 , a small spiral bevel gear 14 and a large spiral bevel gear 15 . The two output stage pinion gears 4 and the output stage large gear 5 are herringbone gears. The small spiral bevel gear 14 meshes with the large spiral bevel gear 15, and the angle of intersection between the two axes is 90°. The large spiral bevel gear 15 and the input stage pinion 2 are connected to the split torque input shaft 1; the gear system passes through the split torque The input shaft 1 is divided into left and right branches, and each branch has a duplex gear shaft 7 connected to an input-stage large gear 3 and an output-stage pinion 4 . The input stage pinion 2 is processed into one body with the split torque input shaft 1, and meshes with the two input stage large gears 3 respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com