Non-contact type impact wave hyperpressure measuring method

A non-contact, measurement method technology, applied in the direction of measuring device, blasting force measurement, ultrasonic/sonic wave/infrasonic wave, etc., can solve the problems of large shock wave overpressure error, result deviation, and influence on shock wave overpressure propagation, etc., to achieve measurement Accurate, operationally safe results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make it easier for those skilled in the art to understand and implement the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

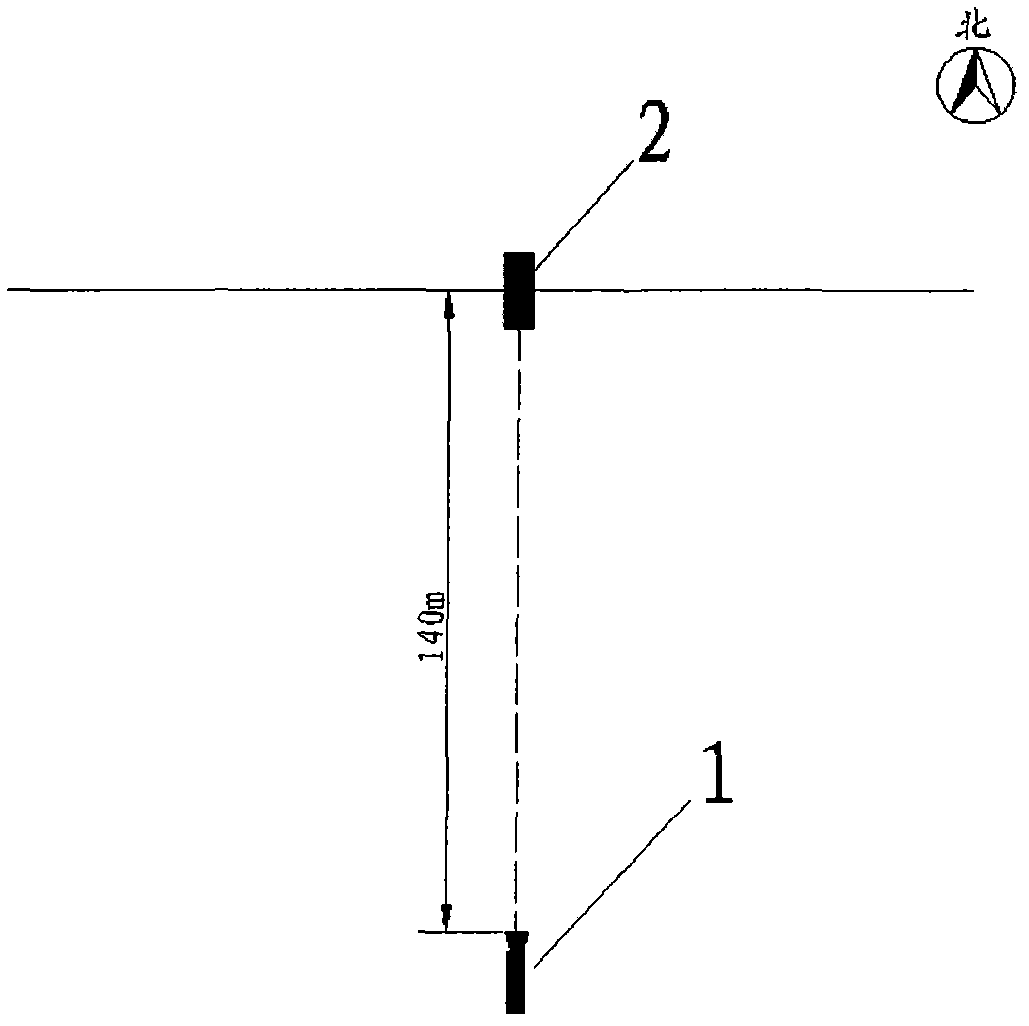

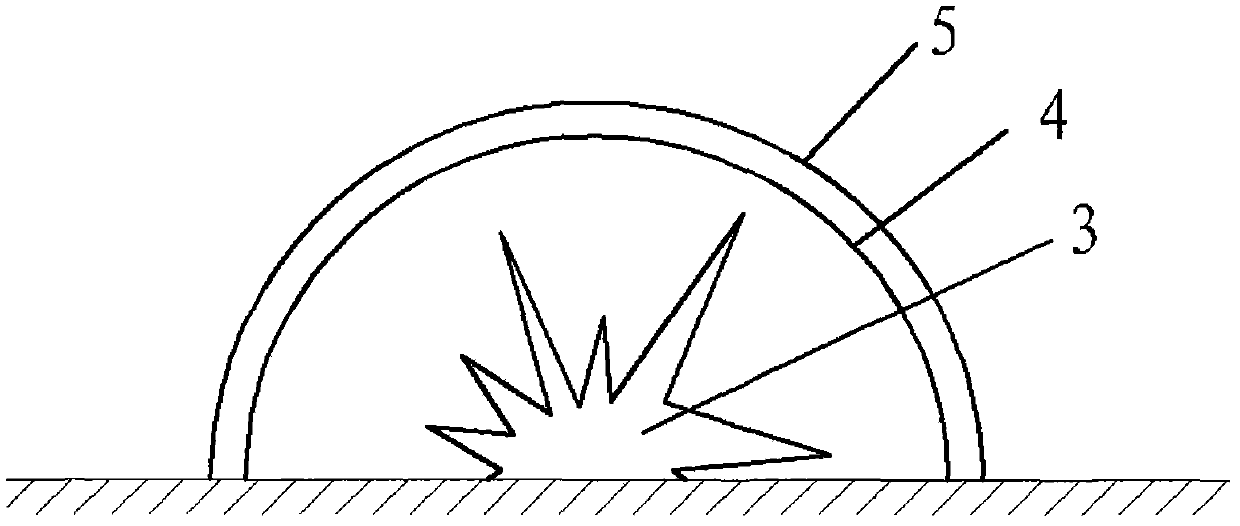

[0023] In order to overcome the shortcomings of the existing shock wave overpressure measurement method, the present invention provides a non-contact measurement method, which can directly observe the propagation process of the air shock wave, and realize the measurement of the air shock wave propagation velocity and overpressure generated by the explosion of various charge structures , its specific scheme is as figure 1 As shown, the high-speed camera 1 is set up in a safe position without any line of sight, and there is a sufficient safety distance between the charge structure 2, such as 140m, or the high-speed camera 1 is set up in a non-safety area affected by the explosion, But take enough protective measures for the high-sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com