Novel capacitance plate suspension structure of differential motion metal capacitance diaphragm capsule

A technology of capacitor plates and metal capacitors, which is applied in fluid pressure measurement, measuring devices, and instruments using capacitance changes, can solve problems such as poor measurement accuracy and stability, and achieve the effect of improving anti-interference ability and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

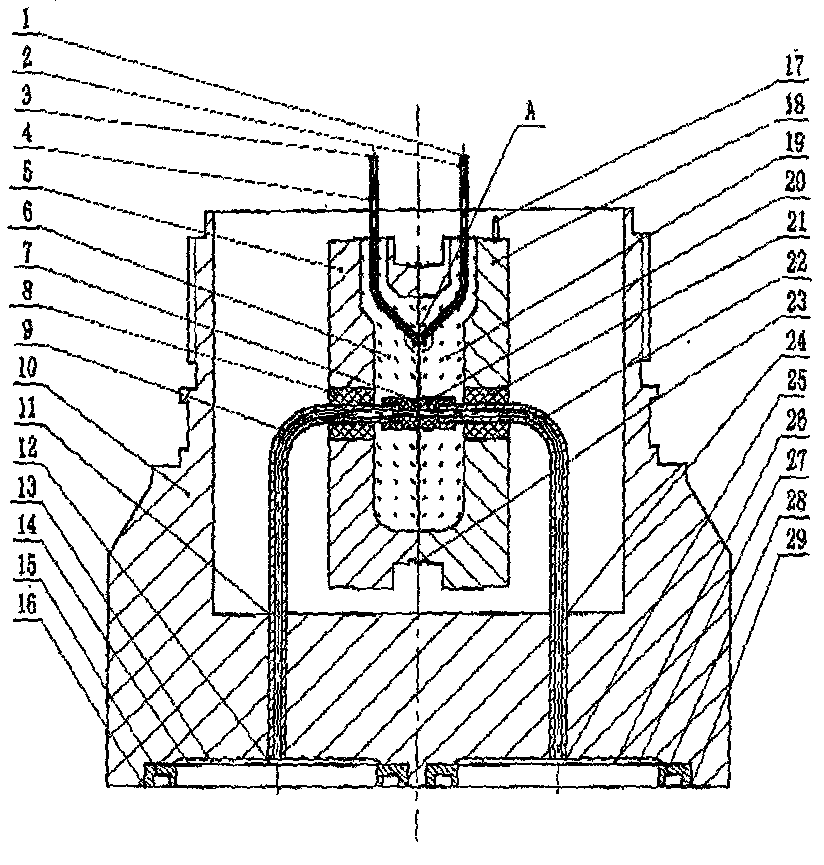

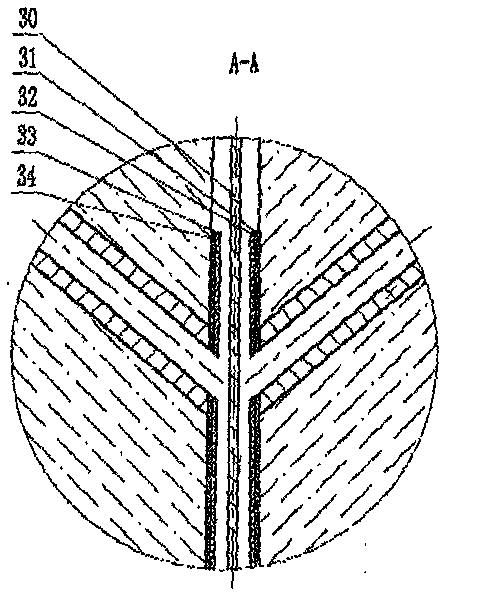

[0016] There is a metal base 10, the lower end of the metal base 10 is provided with an isolation diaphragm 14 (27) and a protective ring 15 (28), and the inner surface of the metal base 10 is connected with a metal pressure guiding tube 9 (22) bent into 90 degrees. ), the lower end of the metal pressure guiding tube 9 (22) is fixed in the metal base 10, and the other end of the metal pressure guiding tube 9 (22) passes through the ceramic ring 8 ( 21) The glass 6 (19) that is arranged on the inner end of the metal half cup body 5 (18) is connected with the ceramic cap 7 (21) fixed in the middle of the glass 6 (19); the glass 6 at the inner end of the metal half cup body 5 (18) (19) The inner upper end is provided with a metal oil-filled pipe 2 (4), and the inner end of the glass 6 (19) is also provided with a conductor film 31 (34), an insulating protective film 32 (33) and a central metal diaphragm 30 successively; Silicone oil 13 (26) is arranged in the middle of sheet 14 (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com