Optical fiber

An optical fiber and light-emitting diode technology, applied in the field of communication, can solve the problems of total reflection, waste of light-emitting diode light source, and low coupling efficiency of optical fiber and light-emitting diode, and achieve the effect of improving the coupling light power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

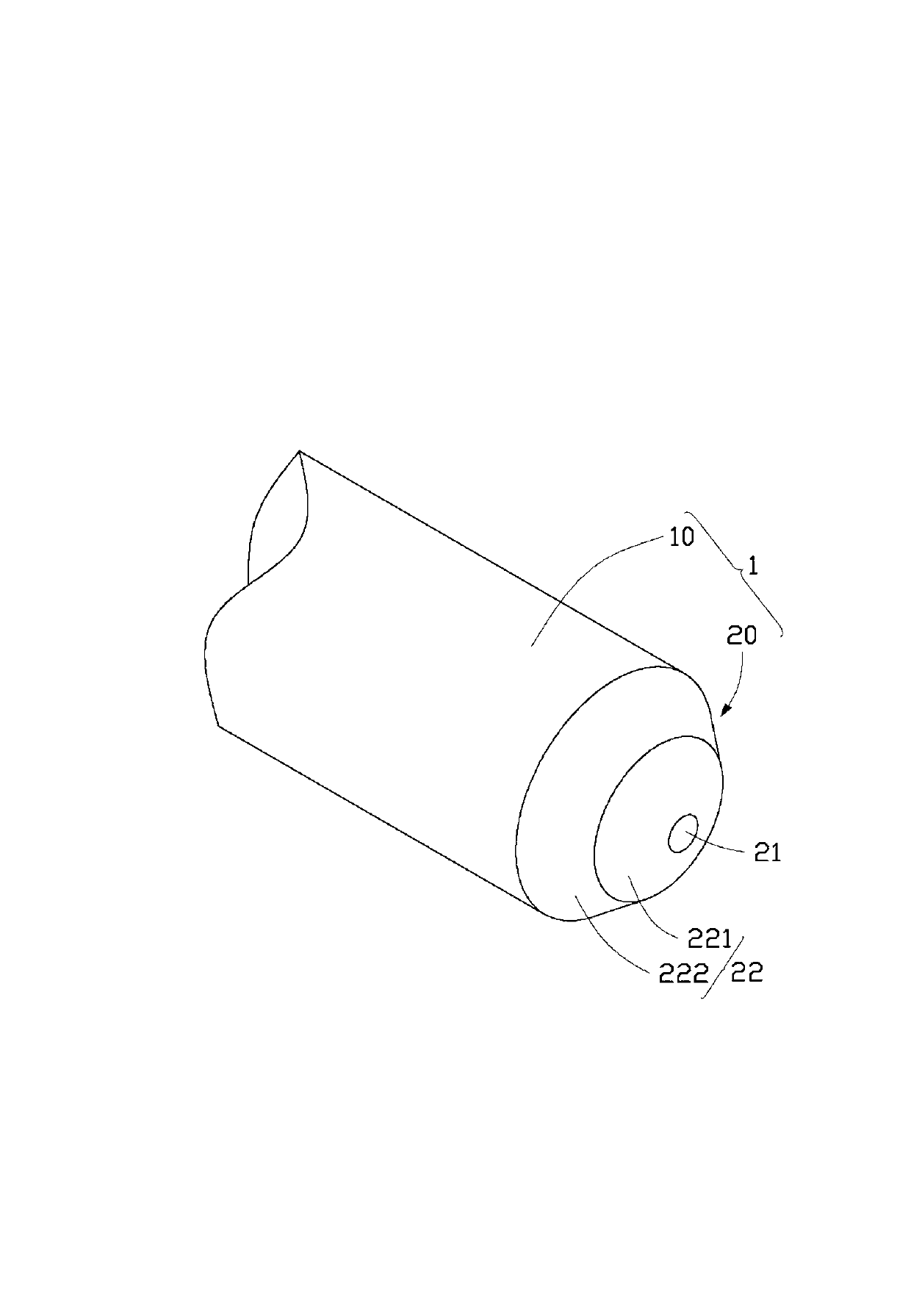

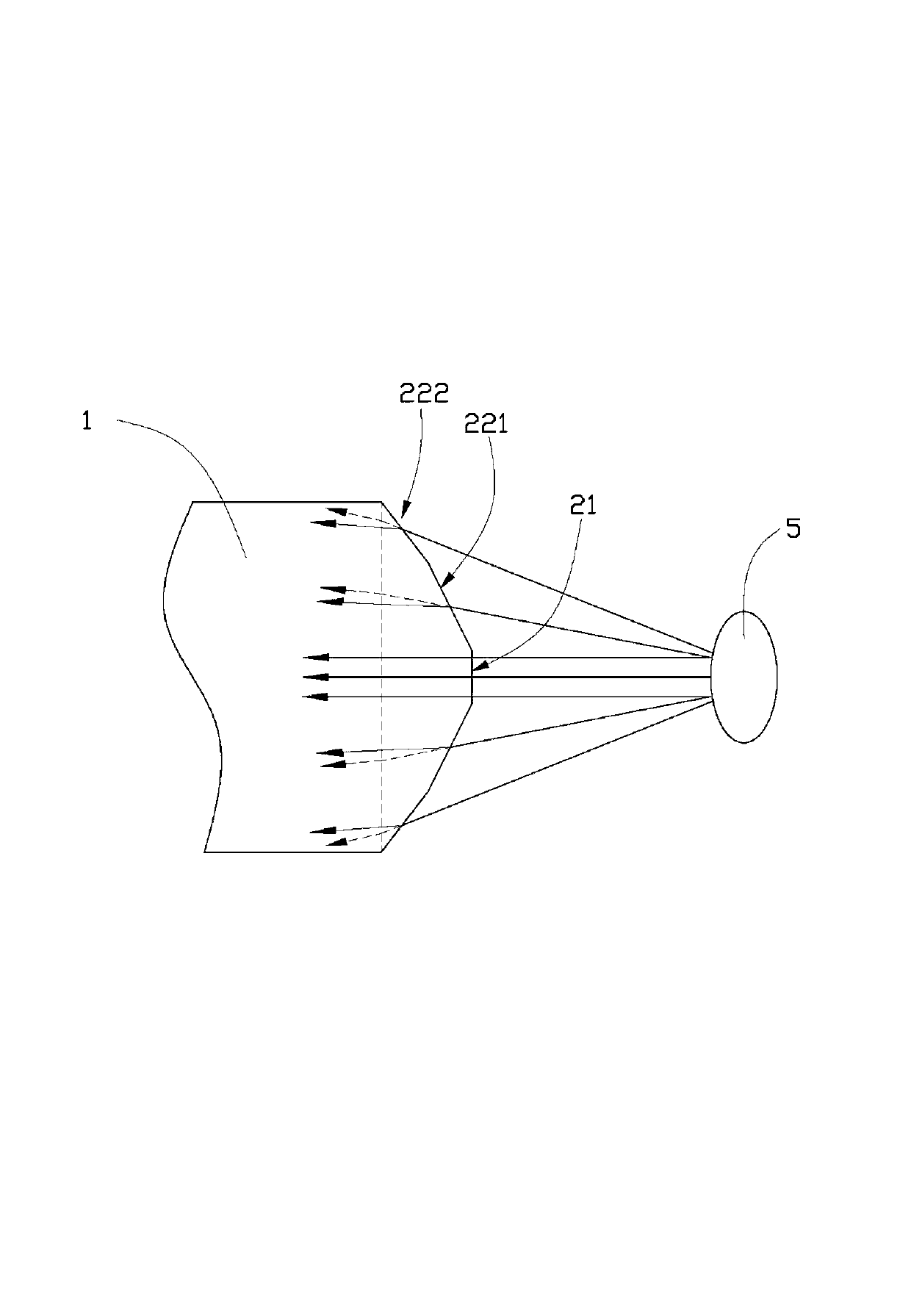

[0012] together with reference figure 1 with figure 2 The optical fiber 1 includes a cylindrical main body 10 and an end 20 , the end 20 is opposite to the LED 5 in use, and the light emitted by the LED 5 enters the main body 10 of the optical fiber 1 from the end 20 . In this embodiment, the optical fiber 1 is a single-mode fiber (single-mode fiber, SMF).

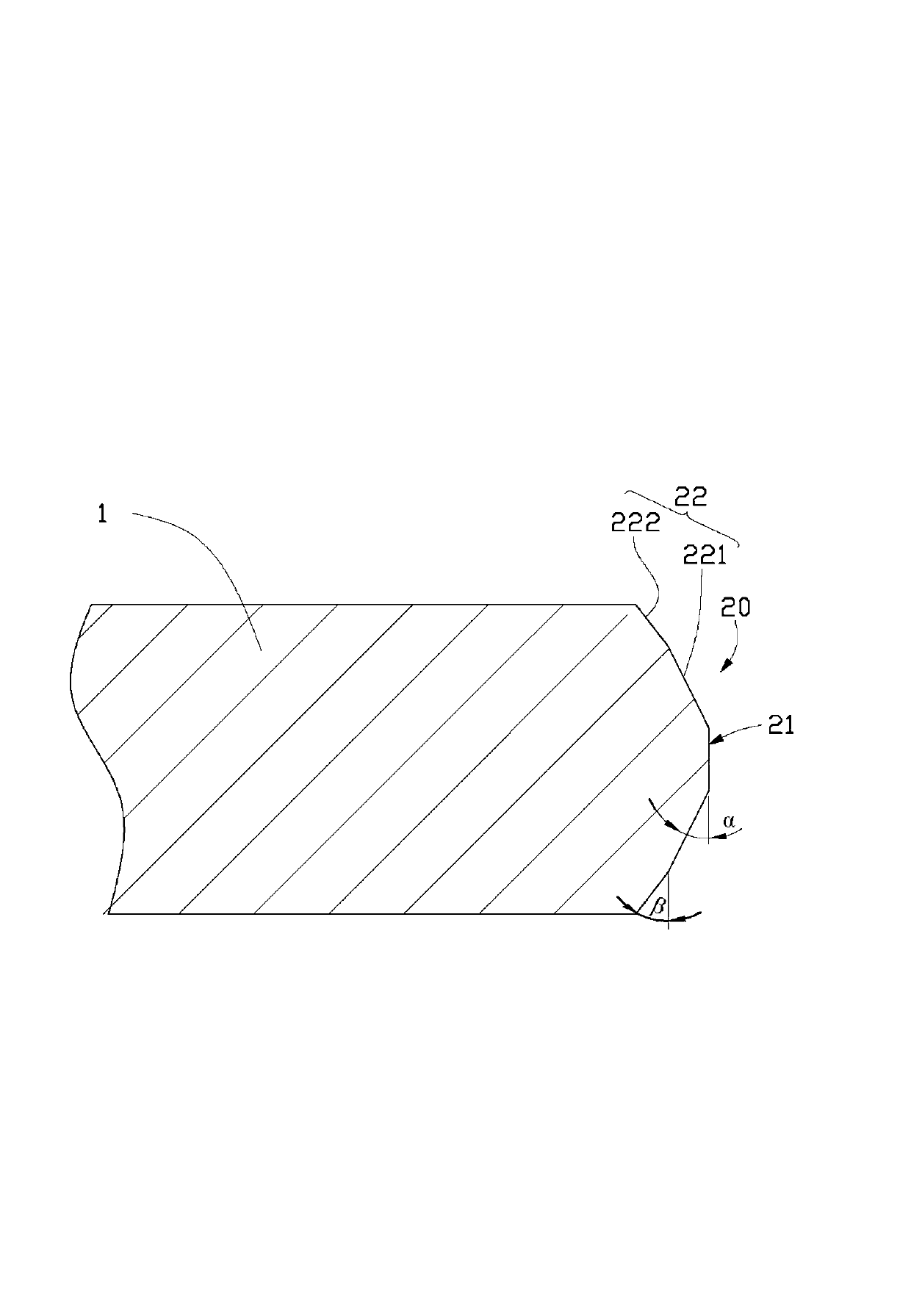

[0013] The end portion 20 includes a vertical and central end face 21 and a cutting face 22 connecting the end face 21 with the cylindrical side of the main body 10 . In this embodiment, the optical fiber 1 is laser cut to form the cut surface 22 .

[0014] The cutting surface 22 includes a first cutting surface 221 connected to the end surface 21 and a second cutting surface 222 connected to the main body 10 . The first cutting surface 221 can be imagined as a circular surface formed by rotating a straight line around the axis of the main body 10 , and there is a small angle α between the straight line and the end sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com