All-fiber bionic compound eye imaging system

A bionic compound eye and all-fiber technology, applied in the field of bionic compound eyes, can solve the problems of difficult to obtain a practical compound eye system, increase the difficulty of system combination, and small size of bionic compound eyes, and achieve improved optical imaging capabilities, stable optical characteristics, and light weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

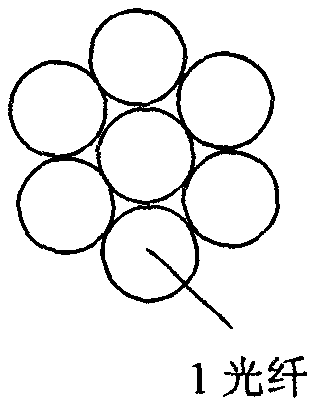

[0034] Constructing all-fiber bionic compound eye with multiple single-core fibers with microlens structure at the end faces

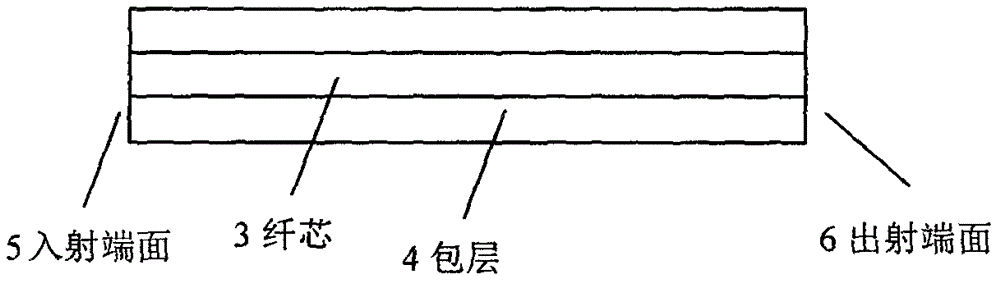

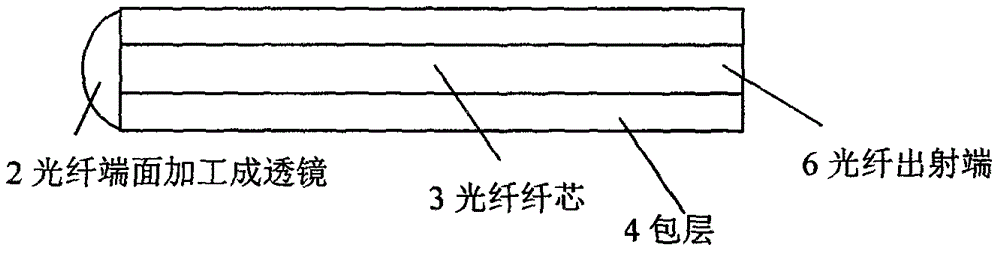

[0035] Such as figure 2 As shown, the single-core optical fiber is composed of a core 3 and a cladding 4, and the two end faces are the light entrance end 5 and the light exit end 6, respectively. By processing the incident light end face 5 of the single-core fiber and processing it into a lens 2 to achieve the function of the bionic cornea, the refractive index of the core 3 of the single-core fiber is higher than that of the cladding 4, and the total reflection principle is used. It can confine the incident light beam in the numerical aperture to the fiber core for transmission, just like a natural biological optic nerve. Therefore, the reflected light from external objects is condensed by the fiber end face lens 2 and then transmitted in the fiber core 3, and a CCD or other photodetector is connected to the exit end 6 of the fiber to detect the outgoi...

Embodiment example 2

[0037] Multi-core fiber structure such as Figure 4 As shown, the multi-core optical fiber is composed of multiple cores 3 with high refractive index and a cladding 4 with low refractive index. The distinguishing feature of the multi-core optical fiber is that there are multiple cores 3 in the same cladding 4. The light transmission principle of the multi-core fiber is the same as that of the single-core fiber, that is, the light beam incident in the numerical aperture is bound in the core 3 for transmission by using the principle of total reflection. The light incident end face 5 of the multi-core optical fiber is micro-processed, and the incident light end face 5 of the optical fiber is processed into an array composed of microlenses 2 corresponding to the number of cores 3, and the reflected light of the target object passes through the lens 2 on the light incident end face 5 of the optical fiber. After being converged, it is transmitted in the core 3 of the multi-core optica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com