Optical fiber macrobend coupling structure and processing method based on ultraviolet curing adhesive

A UV curing glue and optical fiber macro-bend technology, applied in the field of sensing, can solve the problems of poor sensor stability and robustness, low macro-bending dark field coupling power, and small sensor range, so as to improve the sensing signal strength and process Process method improvement, the effect of increasing the signal-to-noise ratio of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

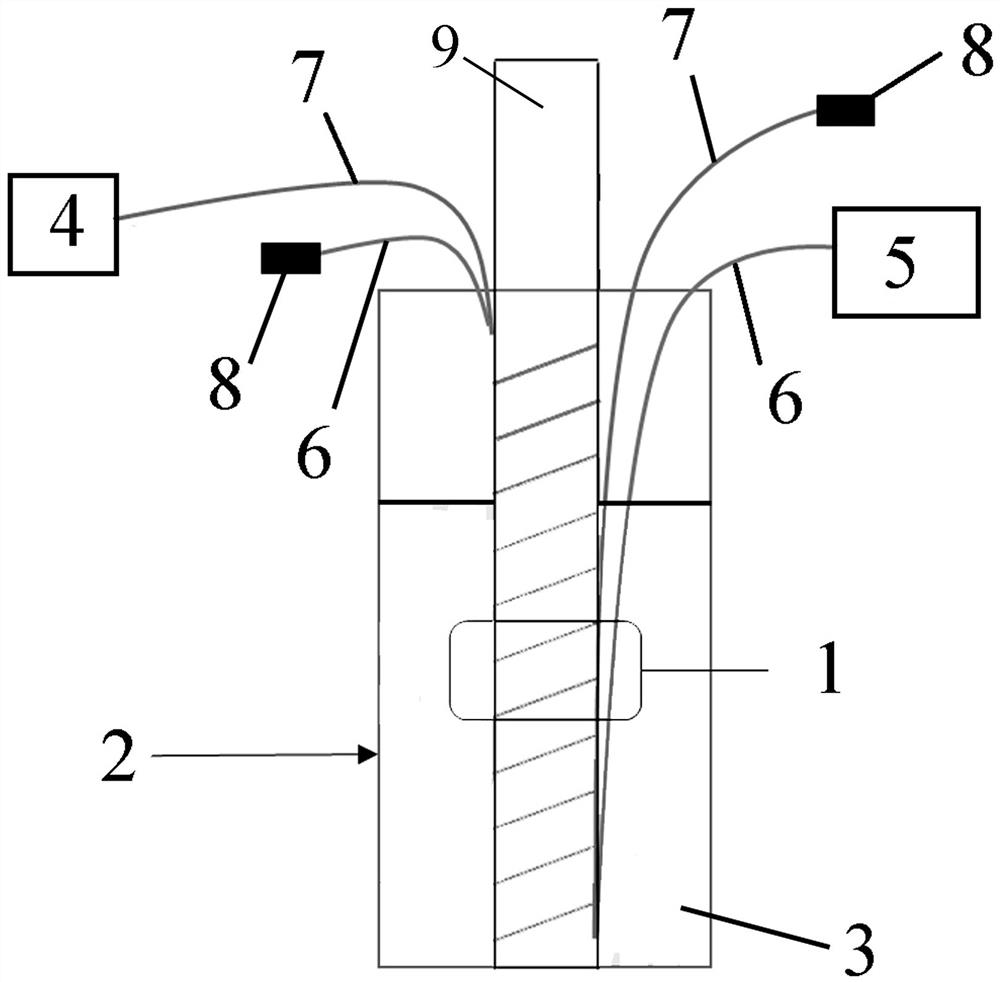

[0032] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

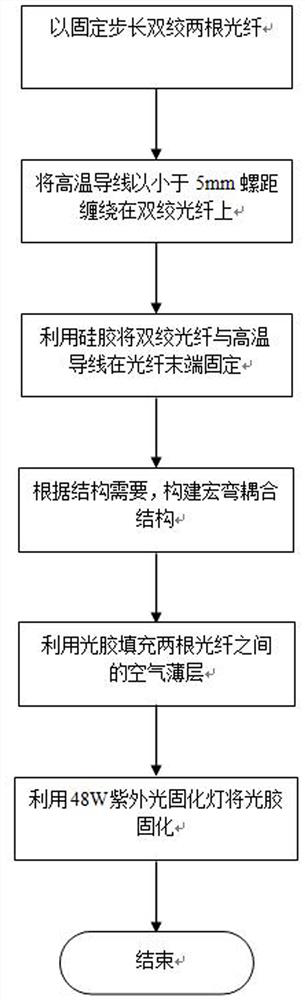

[0033] A processing method of an optical fiber macrobend coupling structure based on UV curing glue, such as Figure 4 shown, including the following steps:

[0034] ① Twist the active fiber and the passive fiber with a fixed step length. During the twisting process, reserve the respective head and end of the active fiber and the passive fiber in the twisted-pair fiber;

[0035] ②Using high-temperature wires to wrap the twisted-pair fiber with a pitch of less than 5mm;

[0036] ③ Coat the head and end of the twisted-pair optical fiber evenly with silica gel, and at the same time wrap the head and end of the high-temperature wire in the silica gel, then put a heat-shrinkable sleeve on the place where the silica gel is applied, and let the silica gel naturally solidify. , passive optical fiber, high temperature wire to form an integrated structure;

[0037...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com