Optical taper type high-power coupler and manufacturing method thereof

A high-power, coupler technology, applied in the field of optical communication, can solve the problems of lens end face and fiber receiving end face damage, air particle breakdown loss of fiber end face, affecting fiber bending loss, etc., to achieve high efficiency and high reliability. Simple, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

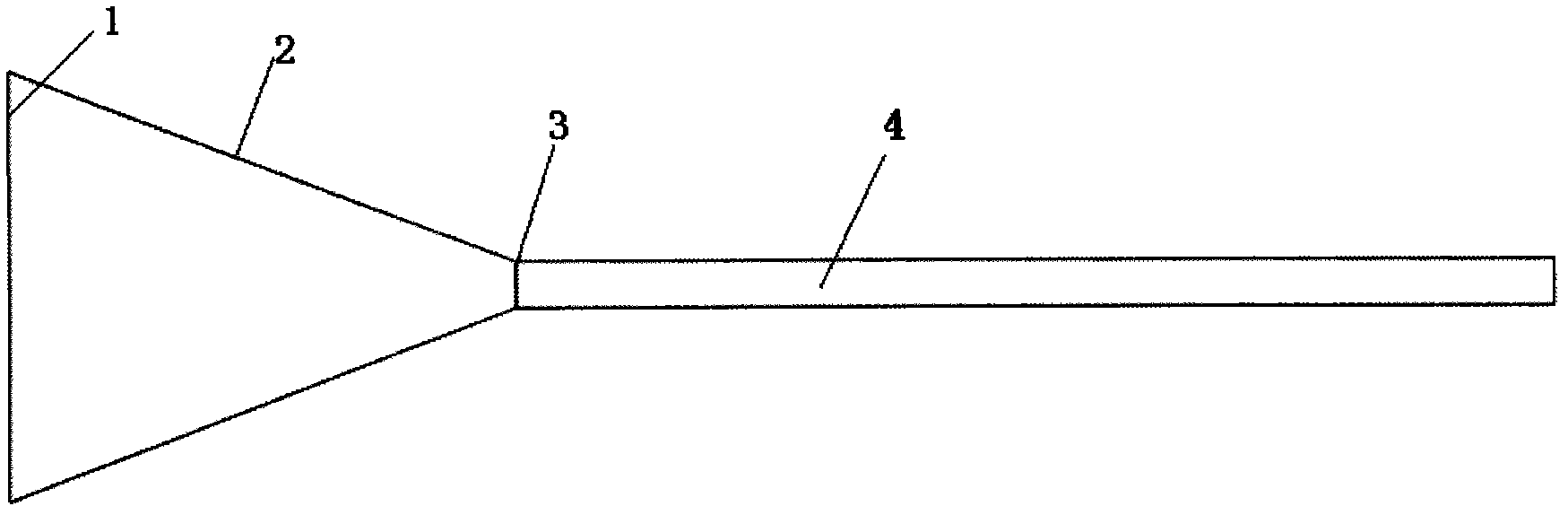

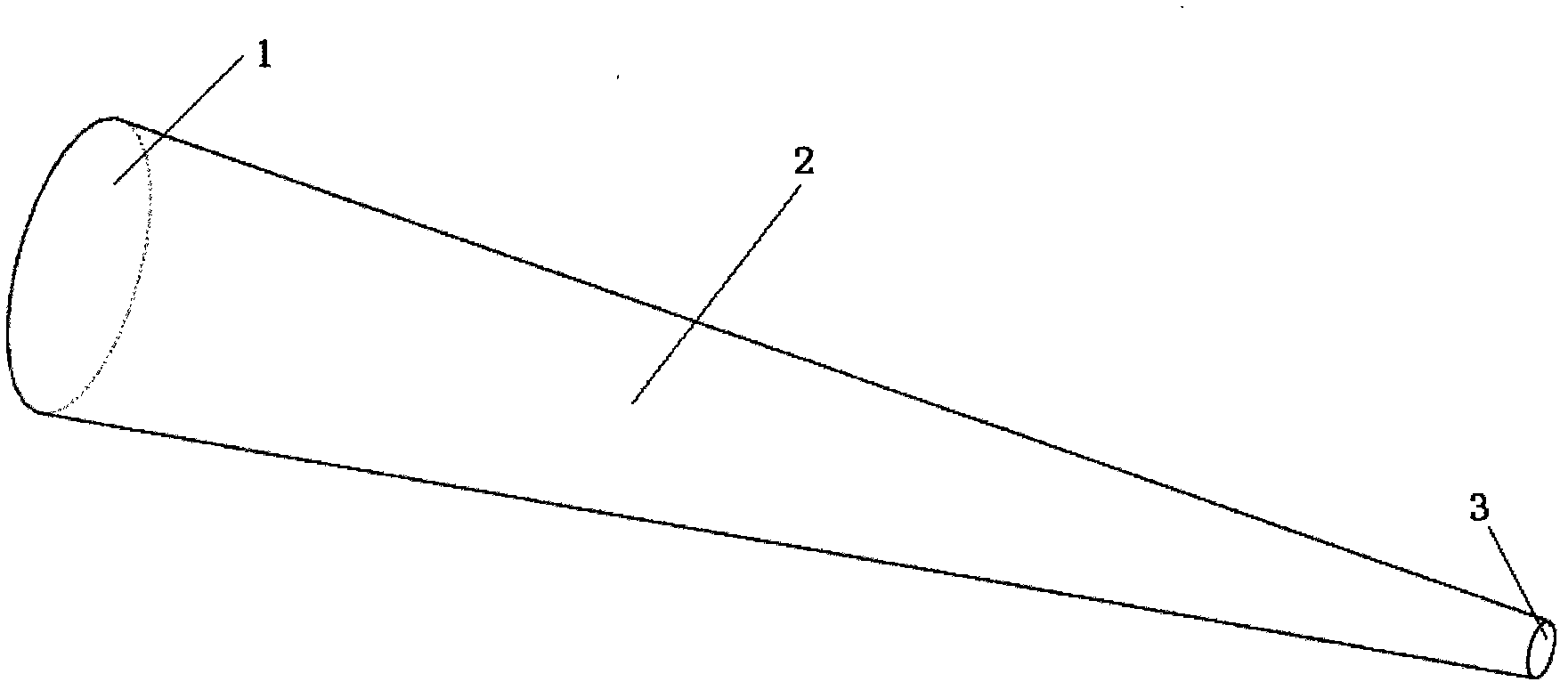

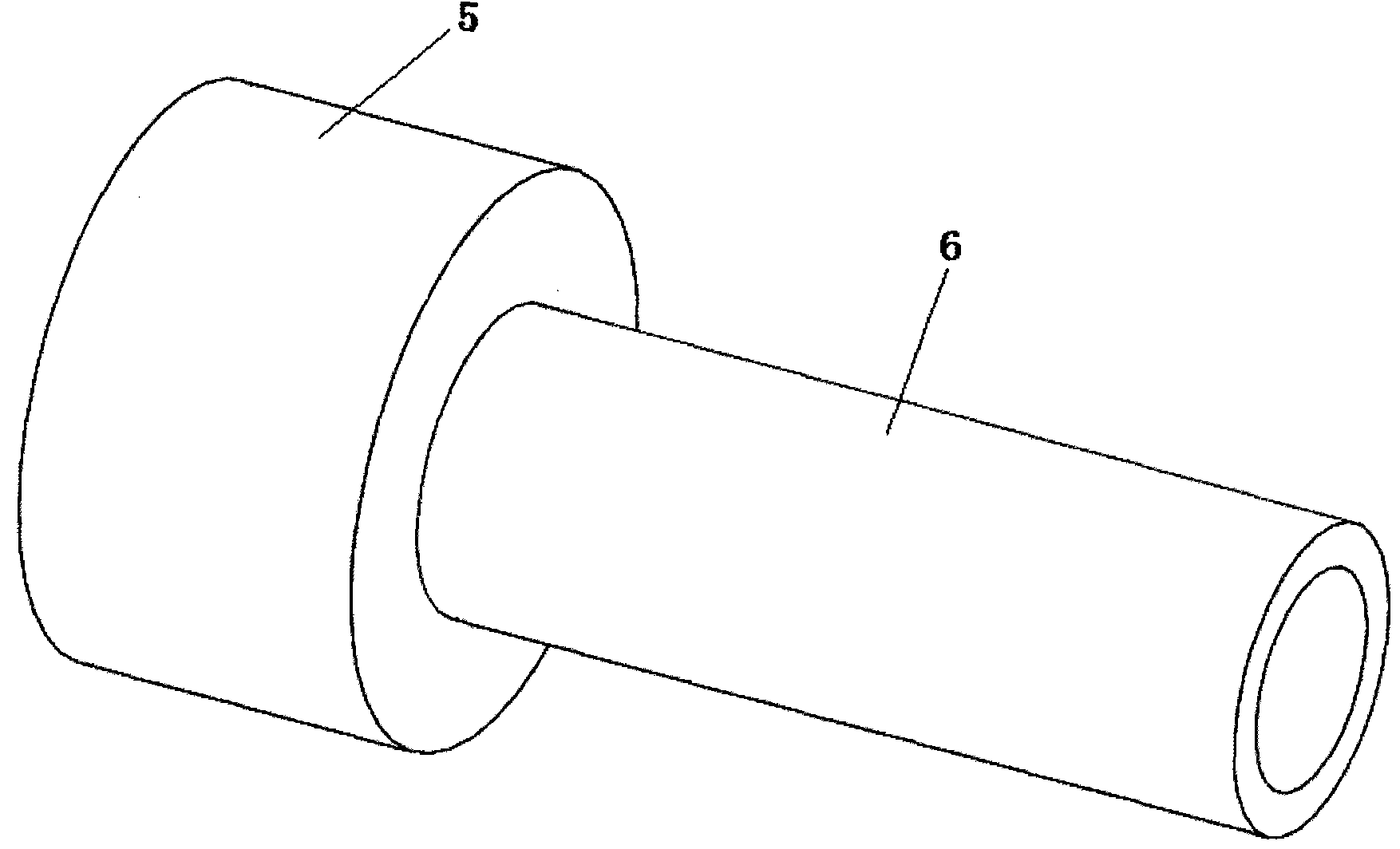

[0044] According to the transmission requirements of high-energy lasers, the diameter of the core area at the thick end of the light cone is required to reach 3.2 mm, and the core diameter of the energy fiber used for laser transmission is required to reach 100 μm. More than 75%. Based on this design purpose, an optical fiber preform with a core-to-clad ratio of 0.8 is firstly prepared using the rod-making equipment. The outer diameter of the optical fiber preform reaches 20 mm, and the core diameter is 16 mm.

[0045] Several hundred meters of energy fiber 4 is drawn by using optical fiber prefabricated rods. The core diameter of energy fiber 4 is 100 μm, and the cladding diameter is 125 μm, and then the remaining rods are used to prepare light cones. Put the remaining rods on the melting tapering machine, first set the diameter of the thick end of the light cone 2 to 4mm, so that the diameter of the core area of the thick end can reach 3.2mm, and perform the first drawing ...

Embodiment 2

[0048] According to the transmission requirements of high-energy lasers, the diameter of the core area at the thick end of the light cone is required to reach 10mm, and the core diameter of the energy fiber used for laser transmission is required to reach 1mm. More than 85%, and the length of the energy fiber is required to be about 100m, and the length of the optical cone fiber integrated coupler is controlled at about 1000mm. Based on this design requirement, an optical fiber preform with a core-to-clad ratio of 0.8 was first prepared using the rod-making equipment. The outer diameter of the optical rod reached 30 mm, and the core diameter was 24 mm.

[0049] Two hundred meters of energy fiber 4 is drawn by using an optical fiber preform, the core diameter of the energy fiber 4 is 1mm, and the cladding diameter is 1.25mm. Then use the remaining rods to prepare light cones, place the remaining rods on the melting tapering machine, first set the diameter of the thick end of th...

Embodiment 3

[0052] According to the transmission requirements of high-energy lasers, the diameter of the core region at the thick end of the light cone is required to reach 16mm, and the core diameter of the energy fiber used for laser transmission is required to reach 1.6mm. The laser transmittance of the integrated high-power coupler with light cone and fiber Reach more than 90%, and require that the length of the light taper fiber integrated coupler be controlled within 2000mm. Based on this design requirement, an optical fiber preform with a core-to-clad ratio of 0.8 was first prepared by using the rod-making equipment. The outer diameter of the optical rod reached 20 mm, and the core diameter was 16 mm.

[0053] Two hundred meters of energy optical fiber 4 is drawn by using an optical fiber preform, the core diameter of energy optical fiber 4 is 1.6mm, and the cladding diameter is 2.0mm. Then use the remaining rods to prepare light cones. Because the diameter of the thick end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com