Precise fiber optic delay line and precise delay control method based on corner cube

A technology of fiber optic delay line and corner cube prism, which is applied in the coupling and coating of mirrors and optical waveguides, can solve the problems of high precision and low insertion loss, achieve small insertion loss, reasonable design, and realize instrumentation and engineering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

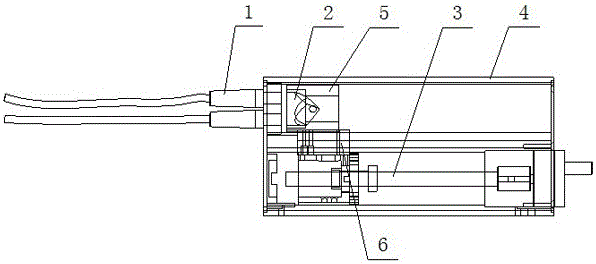

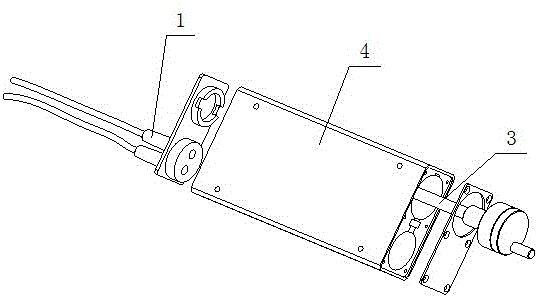

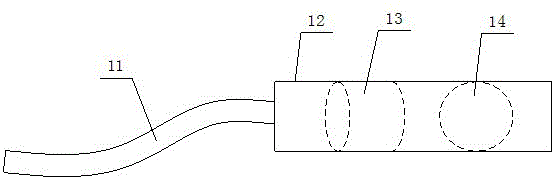

[0028] like Figure 1 to Figure 8 As shown, a precision fiber delay line based on a corner cube prism, including a fiber collimator 1, a corner cube prism 2, a ball screw 3 and a packaging case 4, two fiber optic collimators 1 are installed in parallel on the packaging case 4 At one end, the corner cube 2 and the ball screw 3 are placed in the package housing 4, the chord surface of the corner cube 2 is opposite to the light exit port of the fiber collimator 1, and the chord surface 21 of the corner cube 2 is coated with a pair of Anti-reflection coating with light wavelength of 1550nm, three cones 22 are coated with anti-reflection coating with light wavelength of 1550nm, the whole reflectivity reaches more than 95%, the corner cube prism 2 is fixed in the lens frame 5, and the lens frame 5 passes through the connecting block 6 Connect with ball ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com