Gas compressor on-line characteristic analysis method based on temperature control function of gas turbine

A gas turbine and characteristic analysis technology, applied in the field of electric power industry, can solve the complex problems of gas turbine parameters and characteristics of variable working conditions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

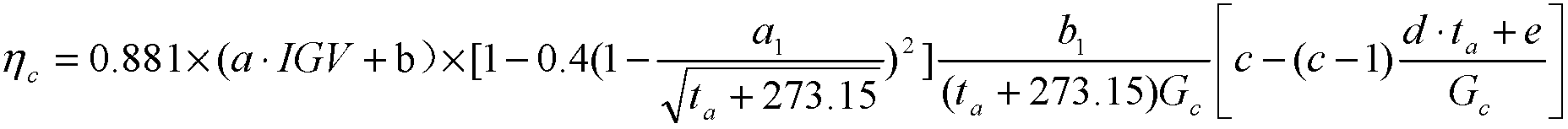

[0055] The specific implementation will be described below by taking a 270MW gas turbine with IGV temperature control of the inlet manifold flow section of the compressor as an example.

[0056] (1) Analyze the rationality of the differential pressure data of the compressor intake manifold.

[0057] Arrange the differential pressure Dp data of the compressor intake manifold according to the IGV opening of the compressor intake manifold flow section from low to high, analyze its distribution, and draw the conclusion that some unreasonable data need to be eliminated.

[0058] Reasonable steps to identify manifold static pressure data are:

[0059] ① According to the original sample (or new sample), fitting Dp (1) =F(IGV,t a ), called the first discriminant.

[0060] Dp (1) =(5.0426×10 -5 IGV 3 -1.1342×10 -2 IGV 2 +2.6784IGV+185.58) / (t a +273.15)

[0061] ② Eliminate unreasonable data in the original sample (or new sample), that is, |Dp-Dp (1) | / Dp (1) ≥5% of the data...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com