Savoury food concentrate

A kind of concentrate and food technology, applied in food science, food preparation, food ingredients as gelling agent, etc., can solve the problems of low processing performance, poor scoopability, hard texture, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0137] method

[0138] Formulations 1a, 1b and 1c (see Table 1) were processed at laboratory scale using the following method (batch size: 1.5 kg):

[0139] Dry ingredients (salt, gelling agents (xanthan gum, locust bean gum), yeast extract, dry flavor imparting ingredients, colorants) were weighed and premixed. Separate starch from other dry ingredients. Water (approximately 40°C), glycerin (when present) and beef extract were mixed into the powder mixture (excluding starch) using a blender to homogenize. With a mixer, additionally mix the melted fat into the mixture. Measure total weight (excluding bowl and whisk). The mixture was heated on a water bath up to 83°C while mixing with a stirrer to activate the gelling agent. The mixture was kept at 83°C for 3 min to simulate the pasteurization step. The total weight before and after heat treatment is compared and the amount of water lost during the process is added. Then, high shear mixing was applied within 1 min using...

Embodiment 2

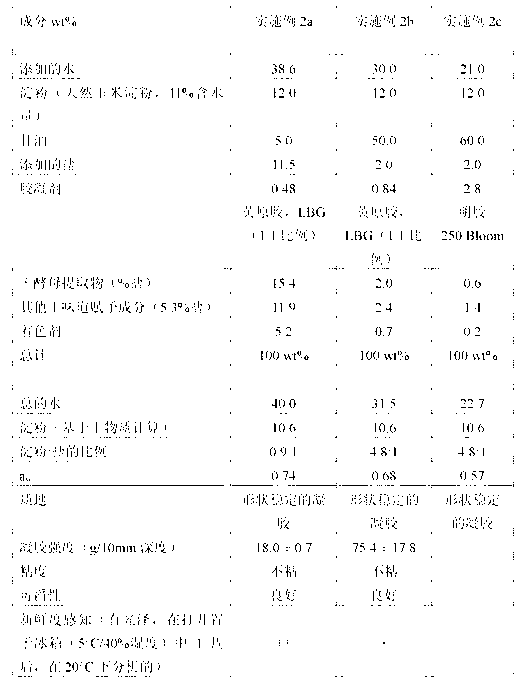

[0146] Example 2 shows formulations according to the invention comprising different levels of glycerol.

[0147] Formulations 2a and 2b were prepared at laboratory scale on a Unimix LM6 using the following method (batch size: 5.5 kg):

[0148] Add liquid ingredients (water, glycerin) to a mixing container. The mixture was heated to 75 °C while applying stirring (150 rpm) and homogenization (5000 rpm) (stirring and homogenization devices were used throughout the process). The premixed dry ingredients (except starch) were added to the mixture at 75°C and the product was further heated during homogenization to dilute the entire powder mixture in water. After pasteurization at 85° C. for 4 min, the mixture was cooled. Add cornstarch natural powder at 68°C (a temperature lower than the gelatinization point of starch), and homogenize within 3min at 8000rpm. Immediately thereafter the product was filled into containers (filling temperature: 62-63° C.), then sealed, and allowed to ...

Embodiment 3

[0153] A food concentrate in the form of a gel was prepared containing the following ingredients:

[0154] Composition (wt%) beef added water 34.3 Heat-moisture treated potato starch agglomerates (13.8% moisture content) 24.3 glycerin 15.4 added salt 5.7 Beef Extract (65°Brix, 35% Water, 8% Salt) 2.9 Yeast Extract (6.2% Salt) 3.5 beef fat 2.4 Other flavor-imparting ingredients (29.1% salt) 9.1 xanthan gum 0.22 Colorant 1.9 Locust Bean Gum 0.22 total 100 total water 38.7 total salt 8.8 Starch:Salt Ratio 2.4:1 % gelling agent / liquid phase 0.81 Aw 0.75 Gel strength (at 20°C) 36.6

[0155] Using a 25 L Fryma Romaco Maxx D vessel and a 25 L Brogtec vessel equipped with a simple stirrer and double jacket, Example 3 was prepared on a pilot plant scale (batch size: 15 kg) using the following method: The liquid ingredients (water , glycerin, beef extract) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com