Rigging system for casting railcar coupler parts

A pouring system and rail car technology, applied in casting and molding equipment, molds, mold components, etc., can solve problems such as increased accident risk and loading offset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

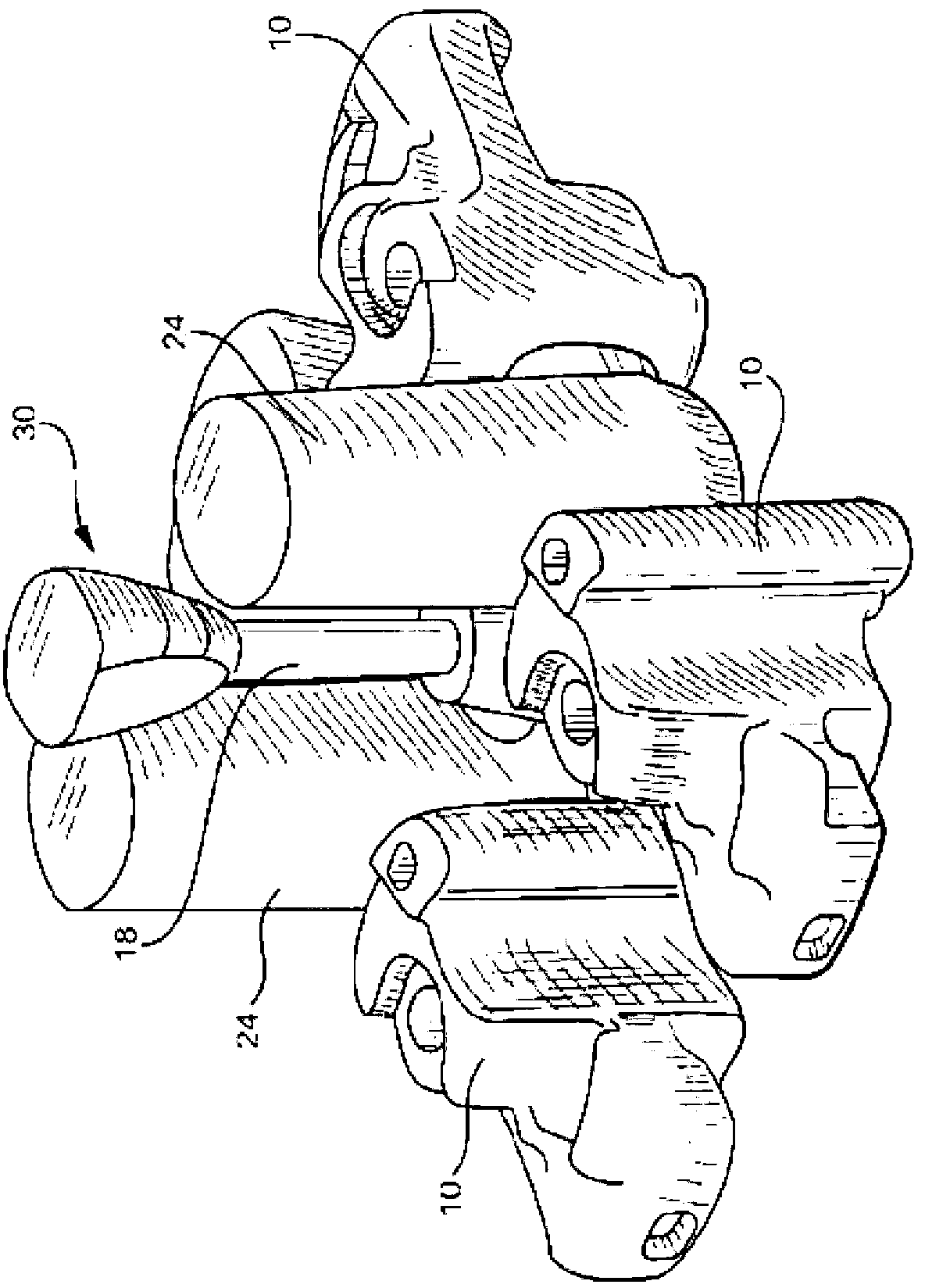

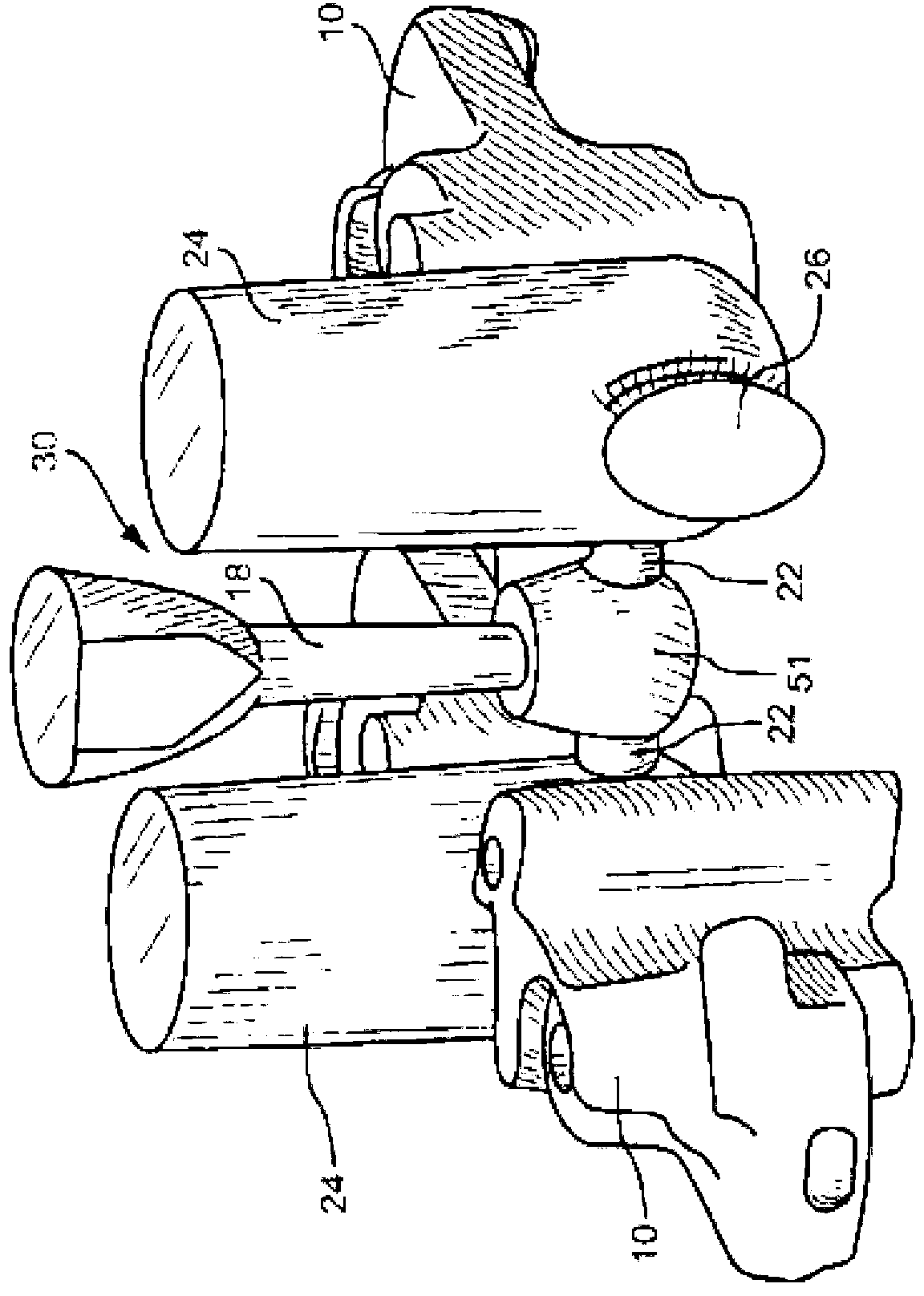

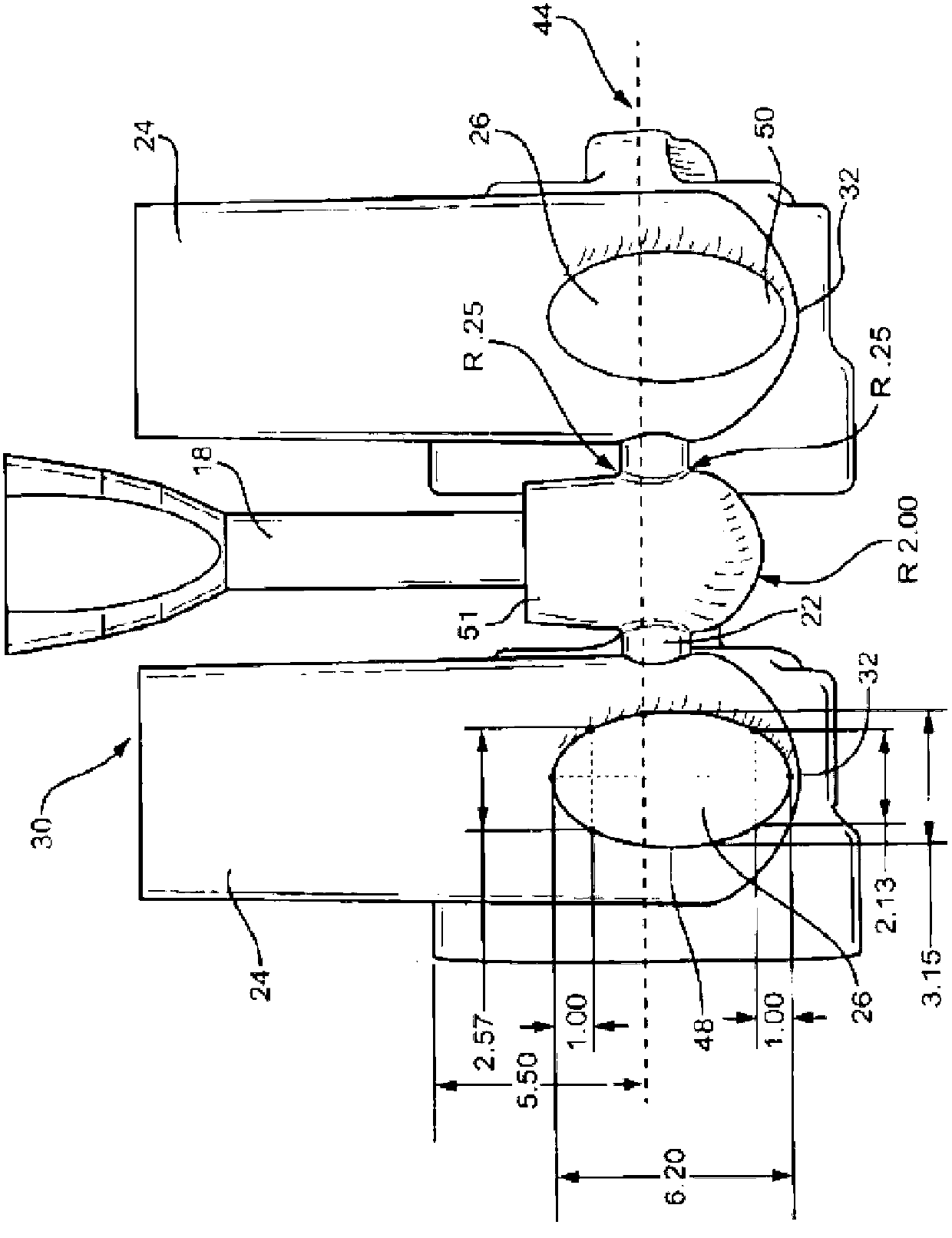

[0077] A gating system (also referred to as a gating system) is described herein for casting railcar coupler knuckles and cores for use in the gating system. Referring to the Figures, in one embodiment, the coupler knuckle 10 is formed from cope (upper) (not shown) and drag (lower) 14 portions of a mold. Copa and drag 14 sections may be formed from "green sand" in a molding box (not shown). In this process, the coupler knuckle pattern is placed in a molding box, onto which wet molding sand (a mix of silica sand, clay, organic binder and water) is poured, compacted and then heated to cure the mold. Removal of the mold leaves a cavity 16 which forms the outer wall of the coupler knuckle 10 . In this process, the mold box is held around the sand mold to maintain the shape of the mold during the metal pouring process.

[0078]In another procedure, coping 12 and drag 14 are formed using a "room temperature setting" procedure in which molding sand is mixed with a binder such as ph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com