Process method for dealumination in jellyfish processing

A process method and dealumination technology, applied in application, food preparation, food science, etc., can solve the problems that jellyfish products are difficult to meet the national standards, and achieve the effect of improving product safety, low cost and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

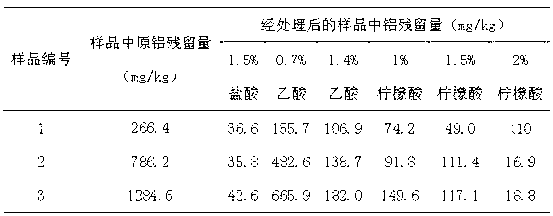

[0028] Embodiment 1. A process for dealumination in jellyfish processing

[0029] Process flow:

[0030] The first step: fresh jellyfish → pretreatment → primary alum → second alum → third alum → drain → set aside;

[0031] Step 2: Three alum jellyfish→soak→rinse→soak in 2% citric acid→rinse again→drain again→shred→seasoning→sterilize→package→inspect→finished product.

[0032] 1) Raw material pretreatment: separate the head and skin of the fresh jellyfish, cut the neck, pier, scrape the red coat, remove the beard from the head of the jellyfish;

[0033] 2) Primary alum, secondary alum, and triple alum: Use 0.4-0.5 kg of alum for every 100 kg. After the alum is completely dissolved, let the jellyfish absorb the alum liquid evenly, marinate for about 20 hours, remove and drain the bittern, and use it as primary alum; Add 4-5kg of alum to every kg of salt, pickle with 15kg of jellyfish and salt-alum mixture per 100kg, sprinkle a layer of salt-alum mixture on the bottom of the p...

Embodiment 2

[0041] Embodiment 2. A process for dealumination in jellyfish processing

[0042] Process flow:

[0043] The first step: fresh jellyfish → pretreatment → primary alum → second alum → third alum → drain → set aside;

[0044] The second step: three alum jellyfish → soak → rinse → shred → soak in 2% citric acid → rinse again → drain again → seasoning → sterilization → packaging → inspection → finished product.

[0045] 1) Raw material pretreatment: separate the head and skin of the fresh jellyfish, cut the neck, pier, scrape the red coat, remove the beard from the head of the jellyfish;

[0046]2) Primary alum, secondary alum, and triple alum: Use 0.4-0.5 kg of alum for every 100 kg. After the alum is completely dissolved, let the jellyfish absorb the alum liquid evenly, marinate for about 20 hours, remove and drain the bittern, and use it as primary alum; Add 4-5kg of alum to every kg of salt, pickle with 15kg of jellyfish and salt-alum mixture per 100kg, sprinkle a layer of s...

Embodiment 3

[0054] Embodiment 3. A process for dealumination in jellyfish processing

[0055] Process flow:

[0056] Step 1: fresh jellyfish → pretreatment → primary alum → second alum → third alum → drain → shred → set aside;

[0057] Step 2: Three alum jellyfish → soak → rinse → soak in 2% citric acid → rinse again → drain again → seasoning → sterilization → packaging → inspection → finished product.

[0058] 1) Raw material pretreatment: separate the head and skin of the fresh jellyfish, cut the neck, pier, scrape the red coat, remove the beard from the head of the jellyfish;

[0059] 2) Primary alum, secondary alum, and triple alum: Use 0.4-0.5 kg of alum for every 100 kg. After the alum is completely dissolved, let the jellyfish absorb the alum liquid evenly, marinate for about 20 hours, remove and drain the bittern, and use it as primary alum; Add 4-5kg of alum to every kg of salt, pickle with 15kg of jellyfish and salt-alum mixture per 100kg, sprinkle a layer of salt-alum mixture...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com