Preparation method of degradable type composite filter rod for cigarette

A technology for composite filter rods and cigarettes, which is applied in the fields of e-liquid filter elements, applications, tobacco, etc., to achieve the effects of reducing pollution, simple methods, and novel and changeable structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

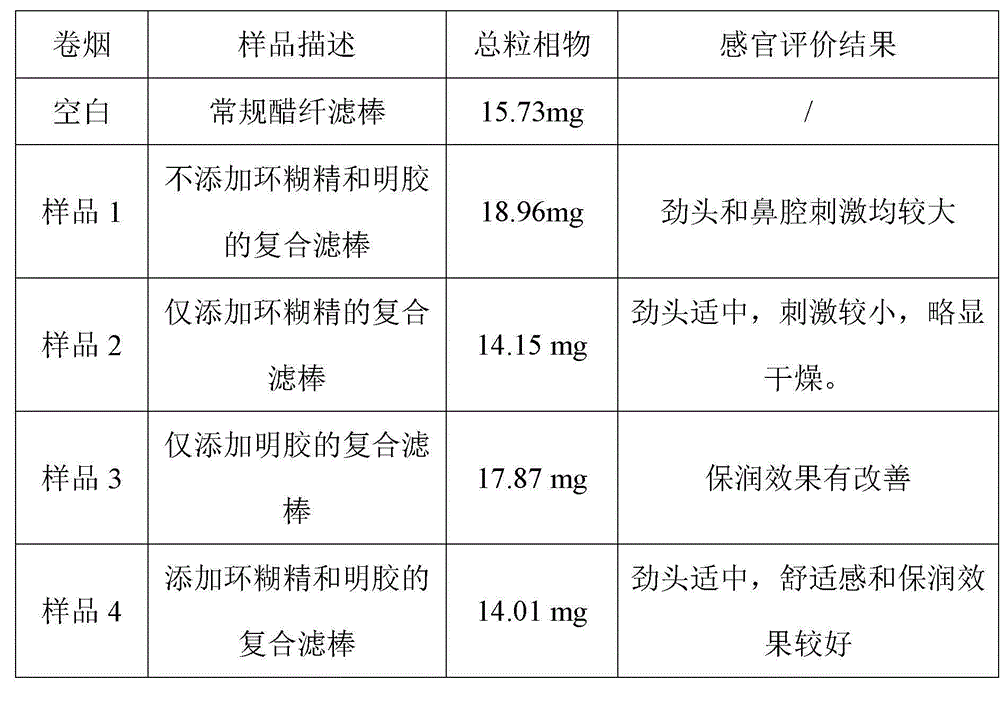

Examples

Embodiment 1

[0023] (1) Cutting and crushing the rice into particles with uniform particle size;

[0024] (2) By weight percentage, 88% chopped rice is fully mixed with 4% cyclodextrin and 8% gelatin;

[0025] (3) In the above mixture, add 83°C water accounting for 10% of the total weight of the mixture, stir and mix for 24 minutes to obtain the puffed material, and pour it into the feeding port of the extrusion puffing machine;

[0026] (4) Under the conditions of extrusion temperature of 120°C and screw speed of 500r / min, the puffed material is extruded and puffed into granules, and cooled to room temperature to obtain puffed filter elements for cigarette filter rods;

[0027] (5) According to the conventional method, use the puffed filter element and conventional acetate fiber tow as materials to prepare binary or ternary composite filter rods.

Embodiment 2

[0029] (1) Cut and crush the corn into particles with uniform particle size;

[0030] (2) By weight percentage, fully mix 65% chopped corn with 23% cyclodextrin and 12% gelatin;

[0031] (3) In the above mixture, add 85°C water accounting for 18% of the total weight of the mixture, stir and mix for 25 minutes to obtain the puffed material, and pour it into the feeding port of the extrusion puffing machine;

[0032] (4) Under the conditions of extrusion temperature of 180°C and screw speed of 240r / min, the puffed material is extruded and puffed into a cylindrical shape with a diameter of 7.0mm, and cooled to room temperature to obtain a puffed filter element for a cigarette filter rod;

[0033] (5) Cut the puffed filter element into a cylinder with uniform length, and then compound it with conventional acetate tow according to the conventional method to prepare a binary or ternary composite filter rod.

Embodiment 3

[0035] (1) Cut and crush the sweet potatoes into particles with uniform particle size;

[0036] (2) Mix 75% chopped sweet potatoes with 10% cyclodextrin and 15% gelatin by weight percentage;

[0037] (3) In the above mixture, add 88°C water accounting for 25% of the total weight of the mixture, stir and mix for 28 minutes to obtain the puffed material, and pour it into the feeding port of the extrusion puffing machine;

[0038] (4) Under the conditions of extrusion temperature of 150°C and screw speed of 380r / min, the puffed material is extruded and puffed into a cylindrical shape with a diameter of 7.5mm, and cooled to room temperature to obtain a puffed filter element for a cigarette filter rod;

[0039] (5) Cut the puffed filter element into a cylinder with uniform length, and then compound it with conventional acetate tow according to the conventional method to prepare a binary or ternary composite filter rod.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com