A main heel Baotou and its preparation method

A main heel and low-melting point fiber technology, which is applied in the field of main heel baotou and its preparation, can solve the problems that the durability of shape retention is not as good as that of leather, impairs sanitation, airtightness, etc., and achieves feasible technology, sufficient raw materials, and improved hygienic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

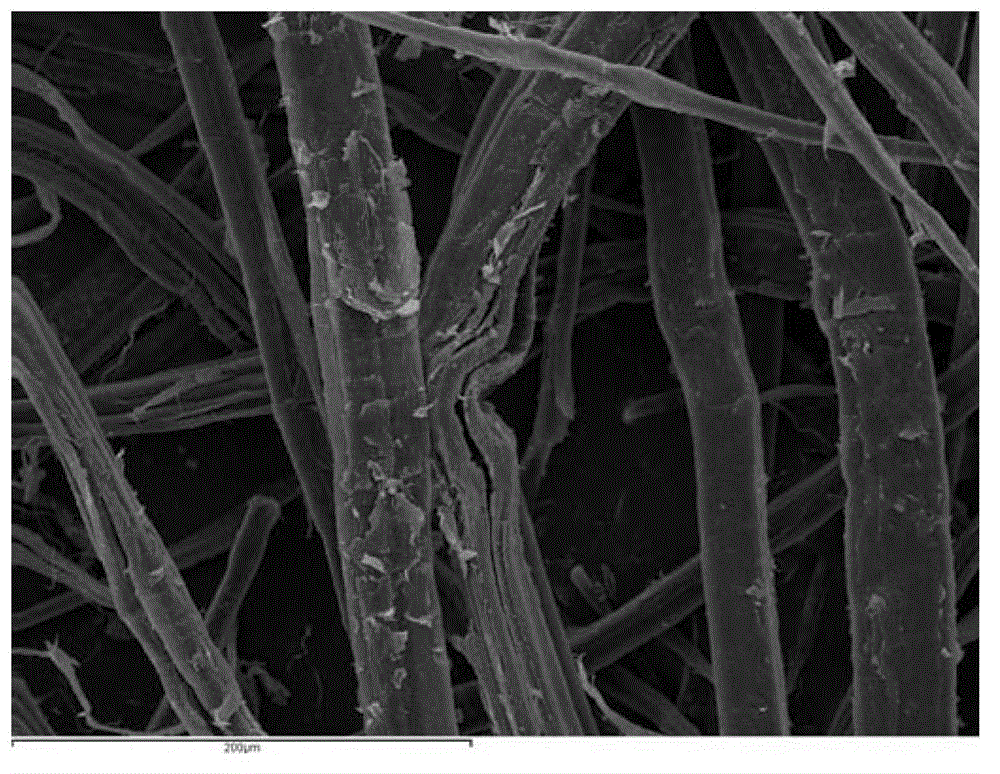

[0024] Embodiment 1, manufacture the main heel toe cap with uniform composition

[0025] 1) Open hemp fiber, polyester and low-melting polyester (melting point is 120° C.), and mix them according to the mass ratio of 40 / 30 / 30 to obtain mixed cotton;

[0026] 2) The mixed cotton is laid, laminated and needle punched to obtain a surface density of 600g / m 2 mixed felt;

[0027] 3) Cut the mixed felt and hot press at 150°C to obtain a preformed main heel toe cap with a thickness of 0.3mm;

[0028] 4) Edge the edge according to the width and thickness of the edge required for shoemaking, and then place it in an oven at a temperature of 130°C until it is basically softened, then take it out, carry out the shoe upper forming operation and the subsequent shoemaking process, that is, the secondary Molded main heel toe cap with uniform components.

[0029] In this example, the hardness of the mixed felt used to prepare the main heel cap is tested according to GB / T2411-2008, reaching ...

Embodiment 2

[0031] Embodiment 2, the manufacture of the main and toe cap with non-uniform components

[0032] 1) Open hemp fiber, polyester and low-melting polyester (melting point 120°C) and mix them in a mass ratio of 30 / 30 / 40 to obtain blended cotton;

[0033] 2) The mixed cotton is laid, laminated and needle-punched to obtain a surface density of 250-300g / m 2 mixed felt;

[0034] 3) Adjust the fiber ratio, repeat step 1) and step 2), and manufacture three kinds of mixed mats with fiber mass fractions of 40 / 30 / 30 and 50 / 25 / 25 respectively;

[0035] 4) Laminate the three kinds of mixed felts prepared above according to the order of natural fiber content from less to more, to obtain mixed felts with non-uniform components;

[0036] 5) Cut the laminated mixed felt and hot press at 120°C to obtain a preformed main heel cap with a thickness of 2.5 mm;

[0037] 6) Edge the edge according to the width and thickness of the edge required for shoemaking, and then place it in an oven at a temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com