Circuit for driving high-power ultrasonic transducer by one square wave

A square-wave drive, high-power technology, applied in the field of circuits, can solve the problems of the single-chip microcomputer program requiring high performance requirements of the single-chip microcomputer itself, and the complicated design of the control circuit of the ultrasonic power supply, so as to achieve high-power ultrasonic signal output, large rated current, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

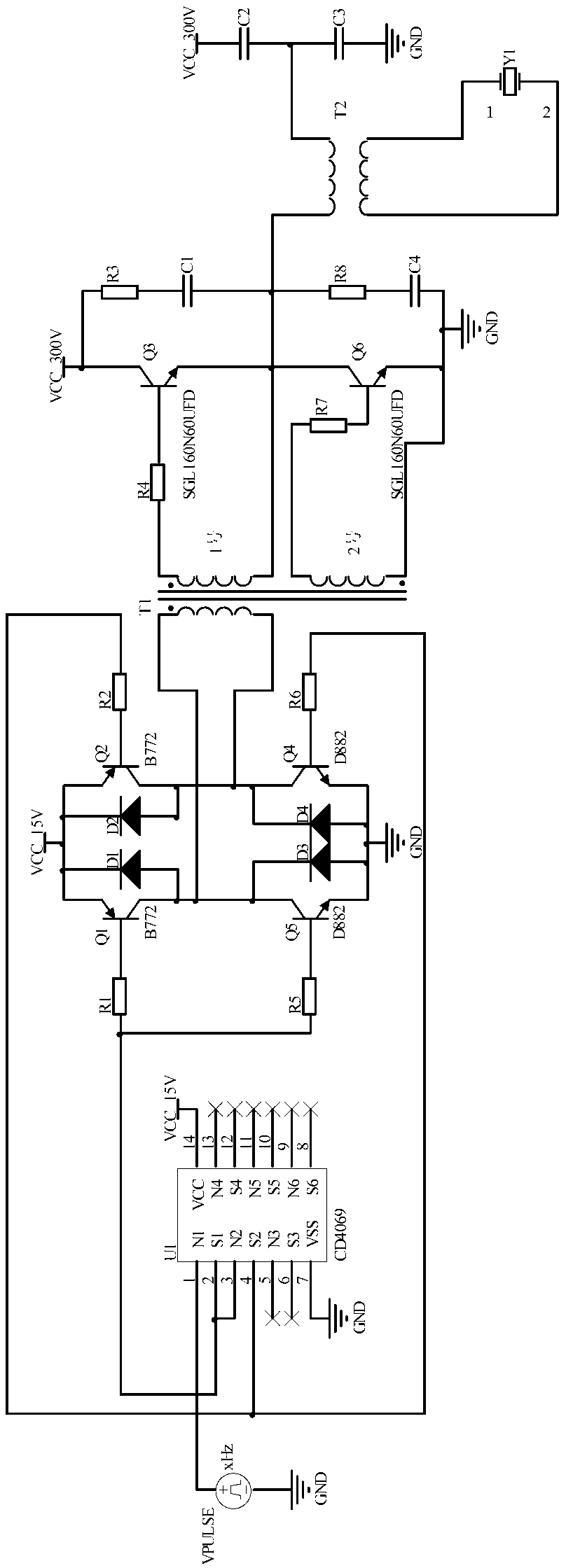

[0009] Such as figure 1 As shown, the circuit for driving a high-power ultrasonic transducer by a square wave includes a pulsed square wave voltage source VPULSE, an inverter U1, a first resistor R1, a second resistor R2, a third resistor R3, a fourth resistor R4, a Fifth resistor R5, sixth resistor R6, seventh resistor R7, eighth resistor R8, first triode Q1, second triode Q2, third triode Q4, fourth triode Q5, first two Diode D1, second diode D2, third diode D3, fourth diode D4, first transformer T1, second transformer T2, first IGBT Q3, second IGBT The polar transistor Q6, the first capacitor C1, the second capacitor C2, the third capacitor C3, the fourth capacitor C4, and the transducer Y1. The signal of the inverter U1 is CD4069.

[0010] One end of the pulsed square wave voltage source VPULSE is grounded, the other end is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com