Continuous-casting tundish slag stopping dam and manufacturing method thereof

A slag retaining dam and continuous casting technology, which is applied in the field of tundish flow field optimization of iron and steel metallurgy continuous casting, can solve the problems of easy cracking and molten steel penetration resistance, etc. Effects of the number of furnaces, uniform molten steel temperature and composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

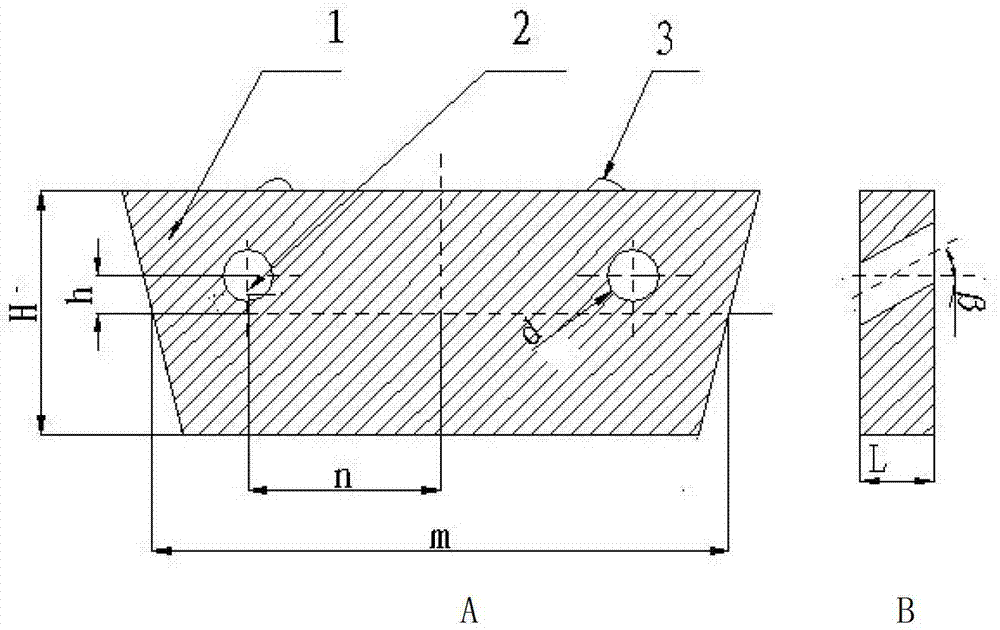

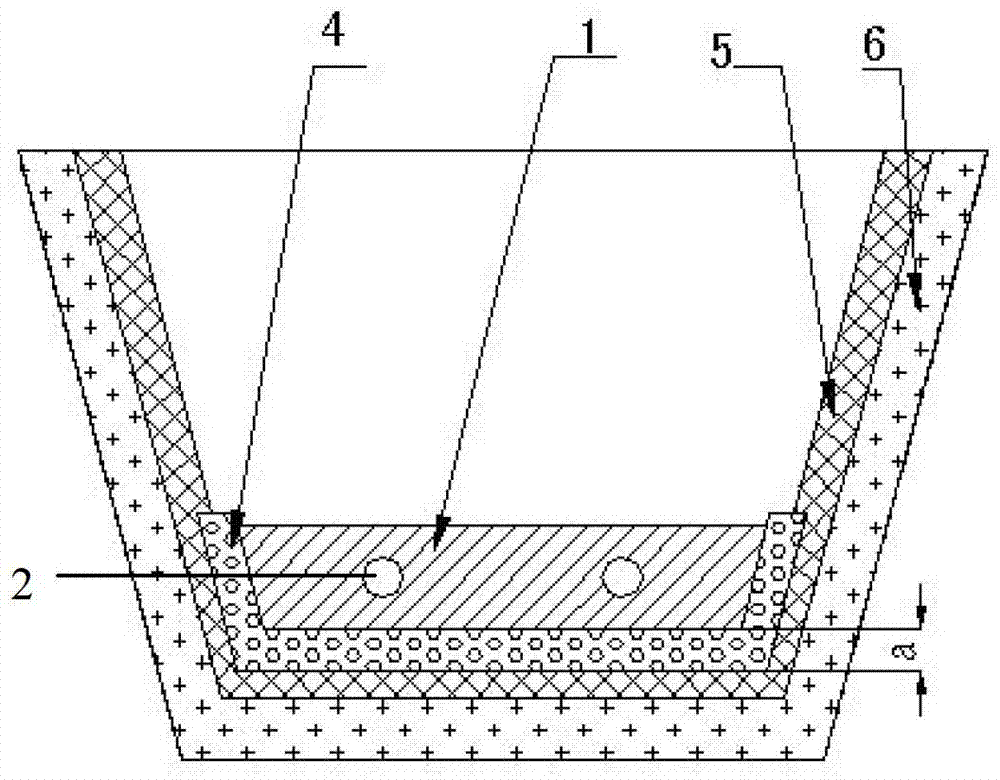

[0045] Continuous casting tundish slag retaining dam, the structure is as follows figure 1 As shown, its longitudinal section is trapezoidal, which is composed of the body 1 of the slag retaining dam, the diversion hole 2 and the lifting ring 3. The two diversion holes 2 are arranged symmetrically with respect to the longitudinal centerline of the slag retaining dam body, and the centers of the diversion holes are respectively located at The left and right 3 / 8 of the longitudinal centerline, that is, n=3 / 8*m, and the center of the diversion hole is located at 1 / 4 above the transverse centerline of the slag retaining dam body, that is, h=1 / 4*H. Two lifting rings 3 are located at the left and right quarters of the body of the slag retaining dam, and the lifting rings are in the shape of "∩"; the height H of the slag retaining dam is 350 mm, and the thickness L of the slag retaining dam is 180 mm.

[0046] In the slag retaining dam of the continuous casting tundish, the upward in...

Embodiment 2

[0055] Embodiment 2, as described in Embodiment 1, the difference is:

[0056] In the slag retaining dam of the continuous casting tundish, the centers of the diversion holes are respectively located at the left and right quarters of the longitudinal centerline, that is, n=1 / 4*m, and the centers of the diversion holes are located 1 above the transverse centerline of the slag retaining dam body / 8, that is, h=1 / 8*H. The height H of the slag dam body 1 is 300 mm, the thickness L of the slag dam body 1 is 160 mm, the upward inclination angle β of the diversion hole 2 is 15°, and the hole diameter d is 70 mm.

[0057] The magnesia spinel castable for continuous casting tundish slag dam is composed of the following materials by weight percentage: 22% of high-purity magnesia with a particle size of 10-5mm, 12% of high-purity magnesia with a particle size of 3mm≦<5mm , 22% of high-purity magnesia with 1mm≦particle size<3mm, 12% of high-purity magnesia with 0.074mm<particle size<1mm,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com