A mold temperature control system and control method

A mold temperature and control system technology, applied in the field of molds, can solve the problems of uneven heating of plastic melt, different thermal conductivity, warping and deformation, etc., and achieve the effects of improving stability, simplifying mold structure, and reducing heat conduction loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

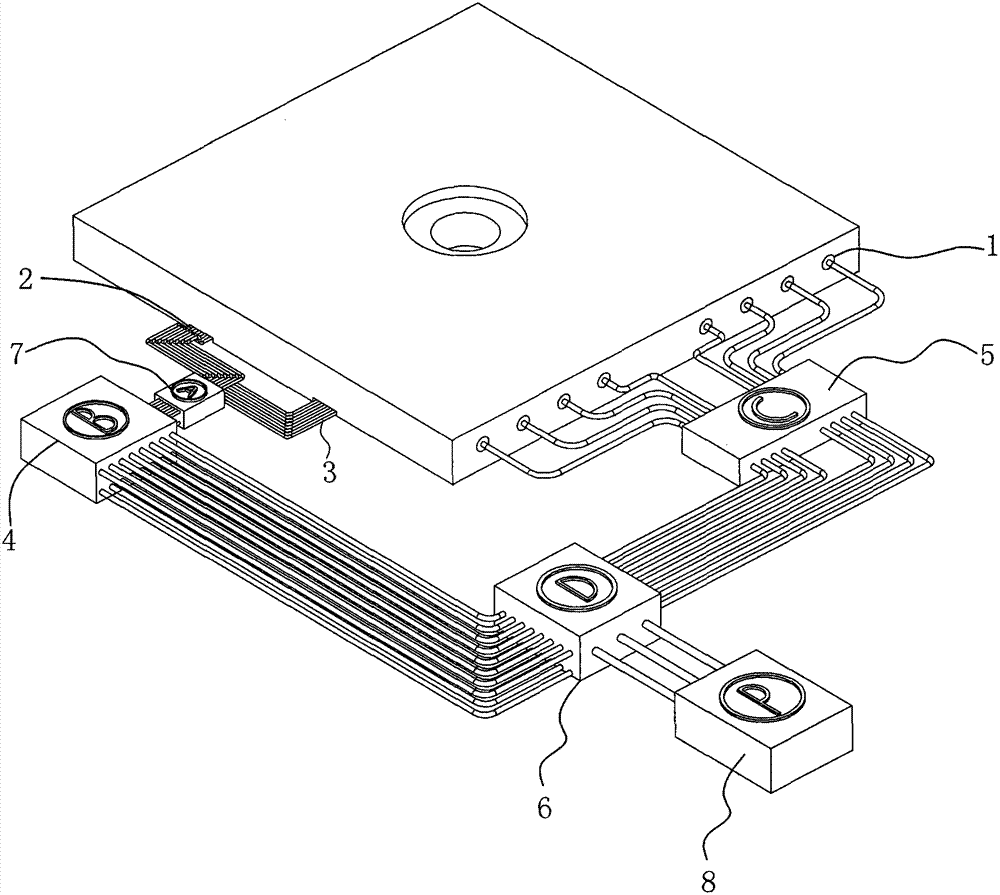

[0032] The mold in the present invention includes a movable template and a fixed template, a mold cavity for molding plastic parts is provided between the movable template and the fixed template, and several heating pipes 1 are respectively provided on the movable template and the fixed template. Eight heating tubes 1 are given in this example, and the number of heating tubes 1 may be ten, twelve, sixteen, twenty, thirty or other different numbers in an actual mold.

[0033] like figure 1As shown, the mold temperature control system of the present invention is arranged on the heating circuit of the heating pipe 1, and all the heating pipes on the fixed plate are connected in a mold temperature control system, which includes a power supply 8 for power supply, Several temperature detection devices for detecting temperature, one or more temperature acquisition instruments 4 connected with the temperature detection devices, and multi-channels connected with the temperature acquisi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com