Integrated brake-by-wire system

An integrated line and brake fluid technology, applied in the direction of brake components, control valves and air release valves, hydraulic brake transmission devices, etc., can solve the problem of increasing production costs, occupying car space, and reducing production costs. The space occupied by the brake system and other problems, to achieve the effect of reducing the occupied space, reducing the installation space and lowering the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

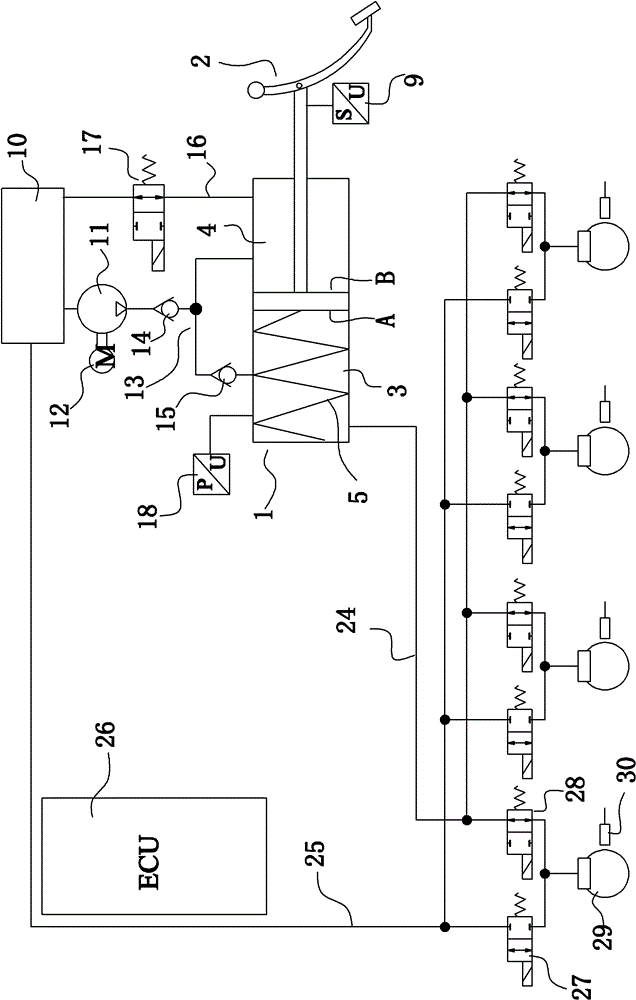

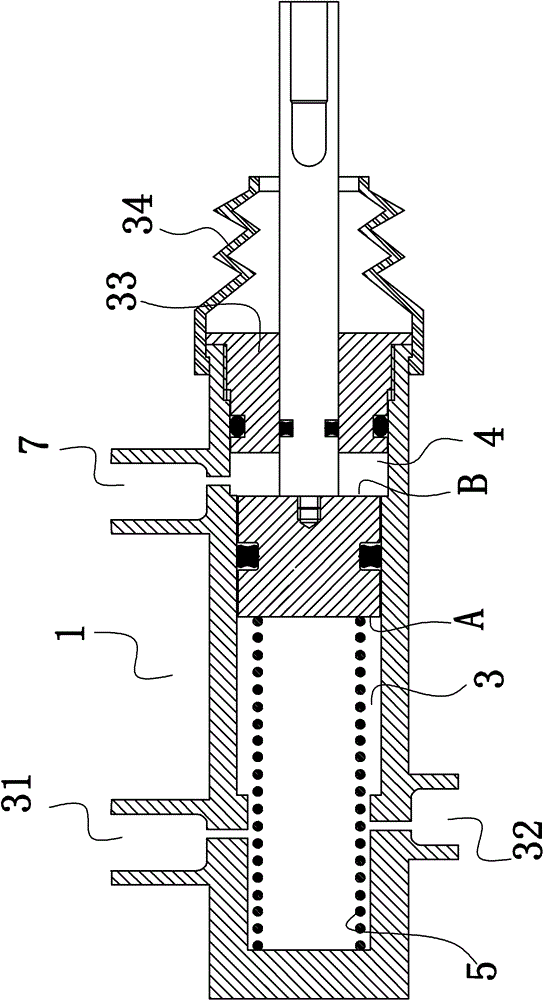

[0033] Embodiment 1: as figure 1 As shown, an integrated brake-by-wire system includes an electronic control unit 26, a brake fluid tank 10, a motor 12, a pump 11, a brake master cylinder 1, a brake pedal 2, a wheel brake 29 and a device for detecting the wheel speed Speedometer 30. A stroke sensor 9 is arranged on the brake pedal 2 . The piston rod on the brake master cylinder 1 is connected to the brake pedal 2; specifically, the brake pedal 2 is provided with a pedal connecting rod opposite to the piston rod of the brake master cylinder 1, and the pedal connecting rod is hinged on the brake pedal. on pedal 2. A counterbore is provided on the outer end surface of the piston rod of the brake master cylinder 1 and the bottom surface of the counterbore is a hemispherical groove. The inner diameter of the smaller one of the counterbores is also larger than the diameter of the pedal linkage. A spherical protrusion is arranged on the end of the pedal connecting rod, the pedal ...

Embodiment 2

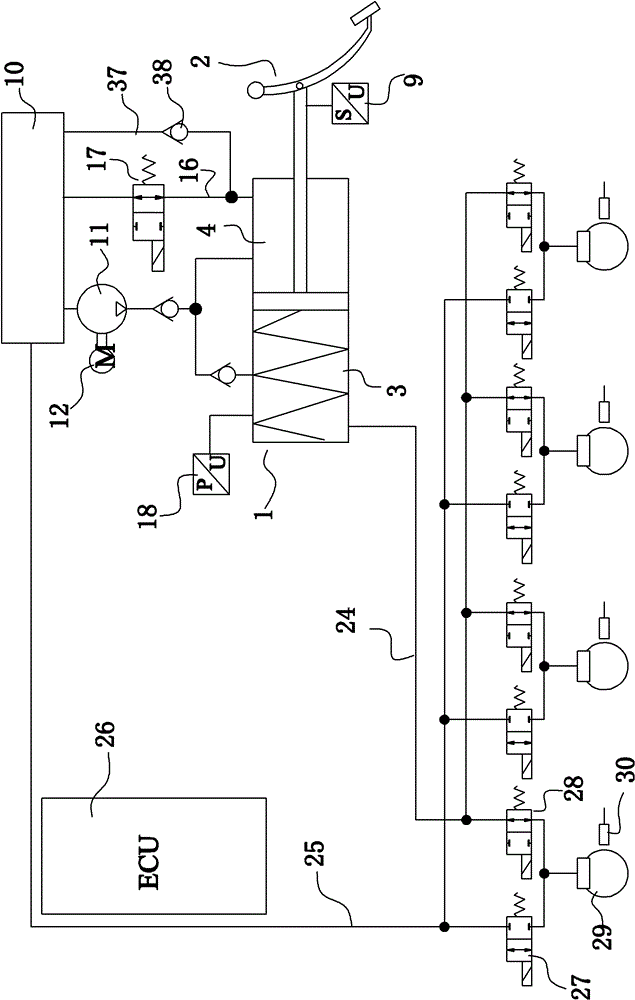

[0044] Embodiment 2: as image 3 As shown, a sixth brake passage 37 is provided between the brake fluid tank 10 and the brake master cylinder 1 , which connects the brake fluid tank 10 and the liquid replenishing chamber 4 . The sixth brake passage 37 is provided with a first one-way valve 38 through which the brake fluid can flow from the brake fluid tank to the liquid replenishing chamber. Refer to Embodiment 1 for the rest of the structure of this embodiment.

[0045] When the brake-by-wire system breaks down, specifically, when the electronic control unit 26 works normally but the motor 12 or the pump 11 breaks down, conventional hydraulic braking can be realized through the cooperation of the sixth brake passage 37 and the first one-way valve 38. At the same time, when the brake-by-wire system works normally, it will not affect the brake-by-wire. Since the flow direction of the first one-way valve 38 is from the brake fluid tank to the liquid replenishment chamber, the ...

Embodiment 3

[0046] Example 3: Figure 5 As shown, one end of the brake master cylinder 1 is provided with an energy storage cavity 39 . A partition 54 is provided between the energy storage chamber and the working chamber 3; a guide hole 50 is provided on the partition to connect the energy storage chamber and the working chamber. The guide flow hole 50 is provided with a fourth one-way valve 52 through which the brake fluid can flow from the working chamber 3 to the energy storage chamber 39 . A piston and an energy storage spring 51 are arranged in the energy storage chamber. A third liquid outlet hole 55 is provided on the cylinder body of the brake master cylinder at the accumulator chamber. A guide rod 6 coaxial with the piston rod of the brake master cylinder 1 is provided on the side of the piston opposite to the working chamber 3 . The guide rod 6 runs through the working chamber 3, the partition plate 54, the energy storage chamber and the piston in the energy storage chamber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com